Researchers from The Hong Kong Polytechnic University (PolyU) have developed a durable, highly selective, and energy-efficient carbon dioxide (CO2) electroreduction system that can convert CO2 into ethylene for industrial purposes.

Ethylene (C2H4), one of the most in-demand chemicals globally, is primarily used for manufacturing polymers such as polyethylene. Polyethylene is used to make some of the most common plastics and chemical fibers.

The problem with ethylene is that it’s mainly obtained from petrochemical sources and the production process involves the creation of a significant carbon footprint.

The research, led by Professor Daniel Lau, Chair Professor of Nanomaterials and Head of the Department of Applied Physics, adopted the method of electrocatalytic CO2 reduction. They used green electricity to convert carbon dioxide into ethylene, which provides a more eco-friendly and stable alternative for ethylene production.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

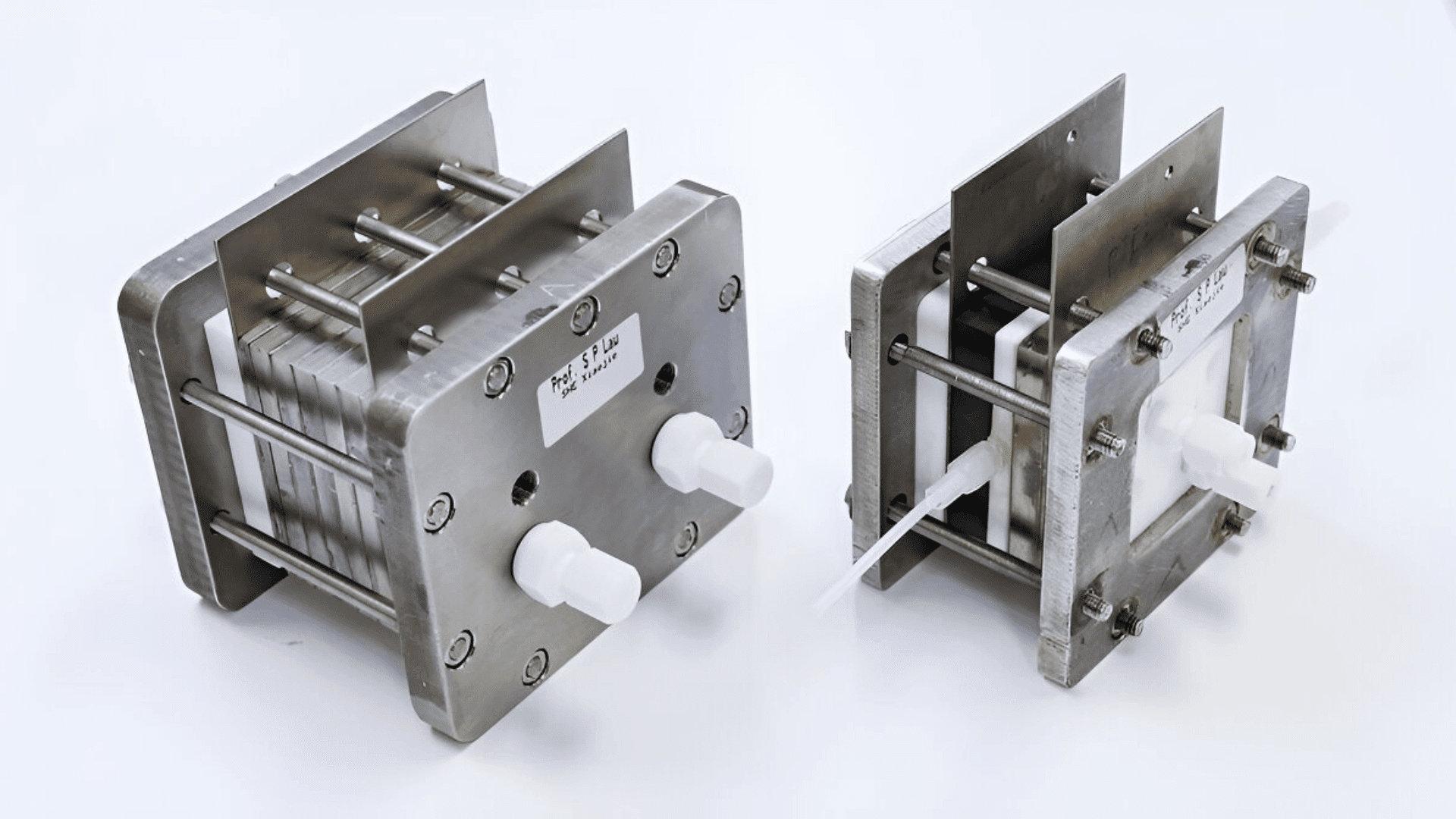

The innovation is to dispense with the alkali-metal electrolyte and use pure water as a metal-free anolyte to prevent carbonate formation and salt deposition. The researchers called their design the APMA system (Anion-exchange membrane, Proton-exchange membrane, and Membrane Assembly).

After the construction of an alkali-metal-free cell stack containing the APMA and a copper electrocatalyst, it produced ethylene with a high specificity of 50%. It also operated for over 1,000 hours at an industrial-level current of 10A.

Further tests showed other improvements over previous systems such as a lack of electrolyte loss and minimizing the formation of hydrogen in competition with ethylene.

The new research won a Gold Medal at the 48th International Exhibition of Inventions Geneva in Switzerland. The research team is working to promote this emerging technology to bring it closer to mass production, which could lead us closer to achieving carbon neutrality.

“We will work on further improvements to enhance the product selectivity and seek for collaboration opportunities with the industry. It is clear that this APMA cell design underpins a transition to green production of ethylene and other valuable chemicals and can contribute to reducing carbon emissions and achieving the goal of carbon neutrality.” Professor Lau stated.