A company is taking sustainable energy one step further. Using low-emission steel, they are creating new wind turbines that “significantly cut down lifetime carbon emissions.” Here is how the company Vestas is doing it.

Vestas 100% steel scraps to make the wind turbines. From there, they melt down the scraps in a furnace powered 100% by wind turbines in their steel mill in Belgium. From the very beginning, the steel they use to manufacture the wind turbines is completely sustainable. After that, they transform the steel into heavy plates used to make the wind turbine towers. These steel plates can be used for both onshore and offshore wind turbine towers. Onshore and offshore are slightly different. Onshore turbines generate power from natural movement in the air. Whereas offshore turbines generate power from the wind.

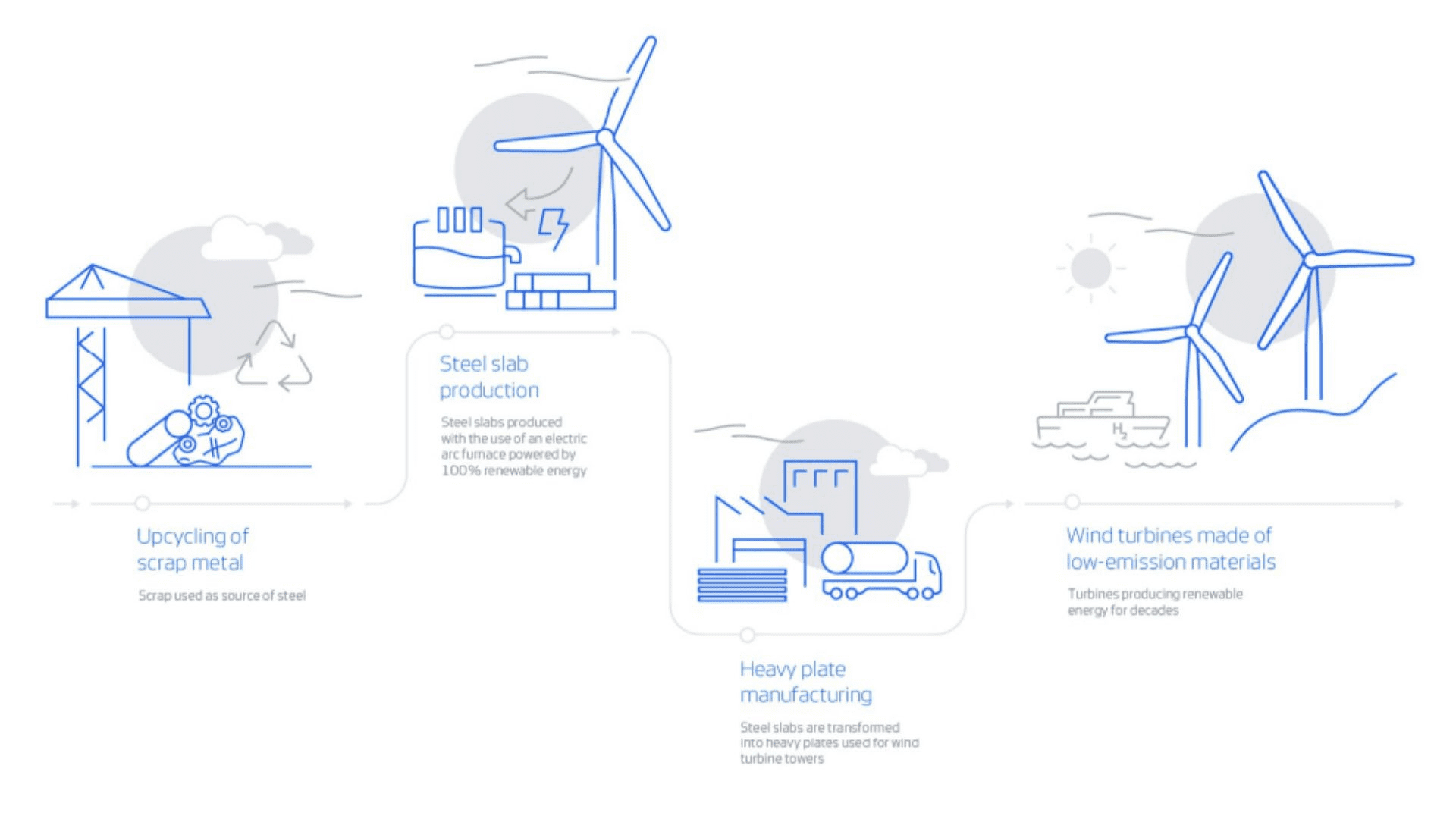

The image below shows the sustainable process that starts with the upcycling of scrap metal. Those scraps are melted down by the furnace powered by wind turbines and turned into steel slabs. After that, Vestas transforms the steel slabs into metal plates. Those metal plates, made from scraps, build wind turbines that produce renewable energy for decades.

By the numbers

When Vestas uses the steel plates for the top two sections of the offshore turbines, the reduction of emissions is 25%. That’s compared to a tower made of conventional steel. For onshore turbines, they can make the whole tower from this steel, and the reduction of emissions doubles at 52%. Steel and iron make up 80-90% of a wind turbine tower. It also accounts for half of the tower’s lifecycle emissions. Vestas aims to reduce carbon emissions in the tower-making process. According to Vestas, the upcycled steel can achieve a 66% decrease in carbon emissions per kg of steel.

Future Plans

Right now, the low emission steel is not a standard for Vestas but there are plans. Next year, the company is putting low-emission steel to use in Poland. The first project for the low emission steel is the Baltic Power Offshore Wind Project. The project in 2025 is an offshore wind farm that is supposed to generate clean energy for about 1.5 million people in Poland. The top sections of 52 of the 76 wind turbines will be of low-emission steel.