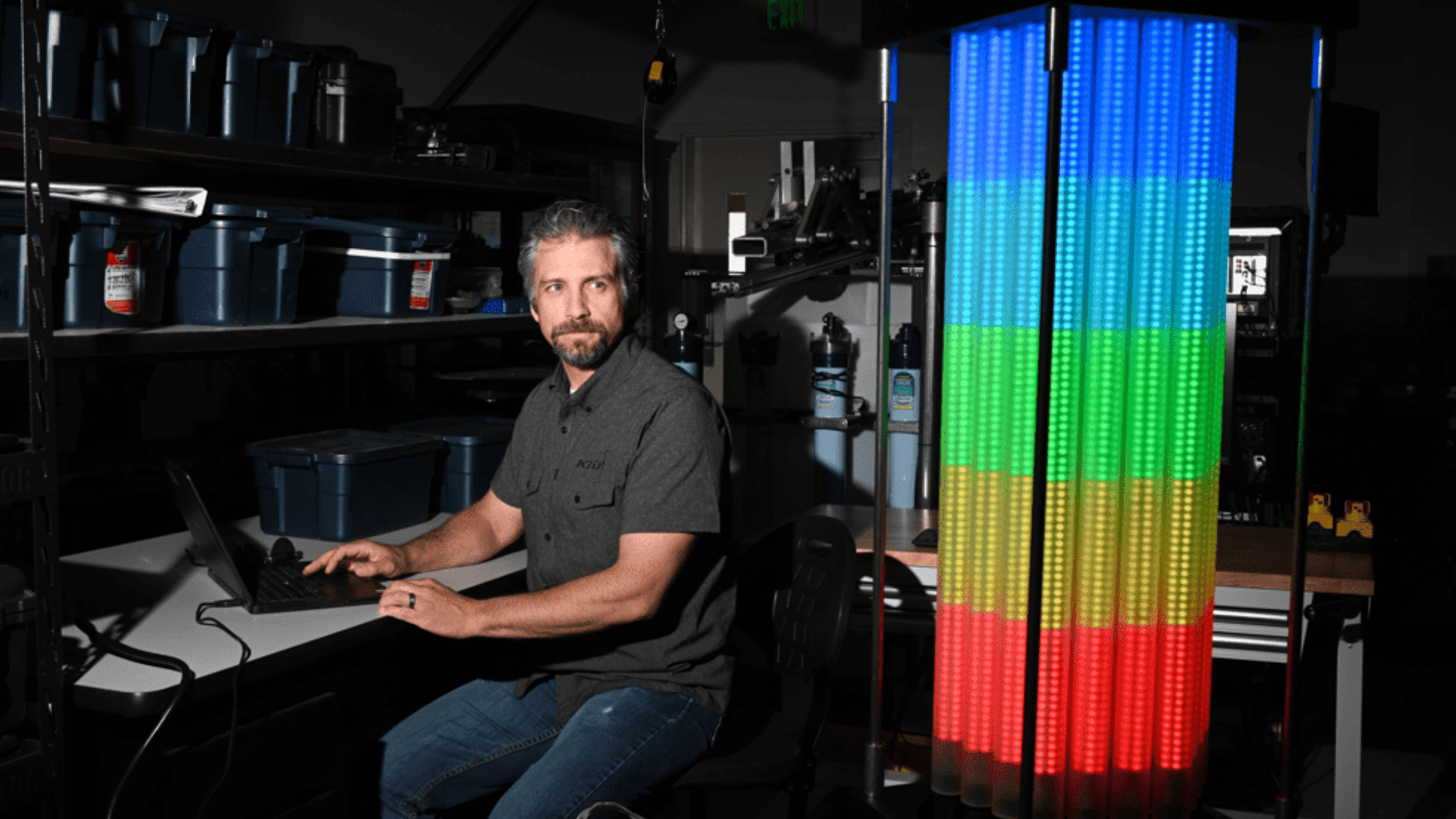

At the Idaho National Laboratory, researcher Ben Baker uses only a laptop to power up a reactor. He types commands that bring the surrogate nuclear reactor to life. The ViBRANT reactor is controlled by the microreactor automated control system (MACS).

However, there were no heavy radiation shields or thick concrete walls required. That’s because this reactor doesn’t run on nuclear fuel. Instead, it uses thousands of LEDs to mimic a real atomic chain reaction. By using particles of light (photons) instead of neutrons, researchers can watch exactly how a reactor behaves without any of the typical hazards.

A Nuclear Reactor Without the Radiation

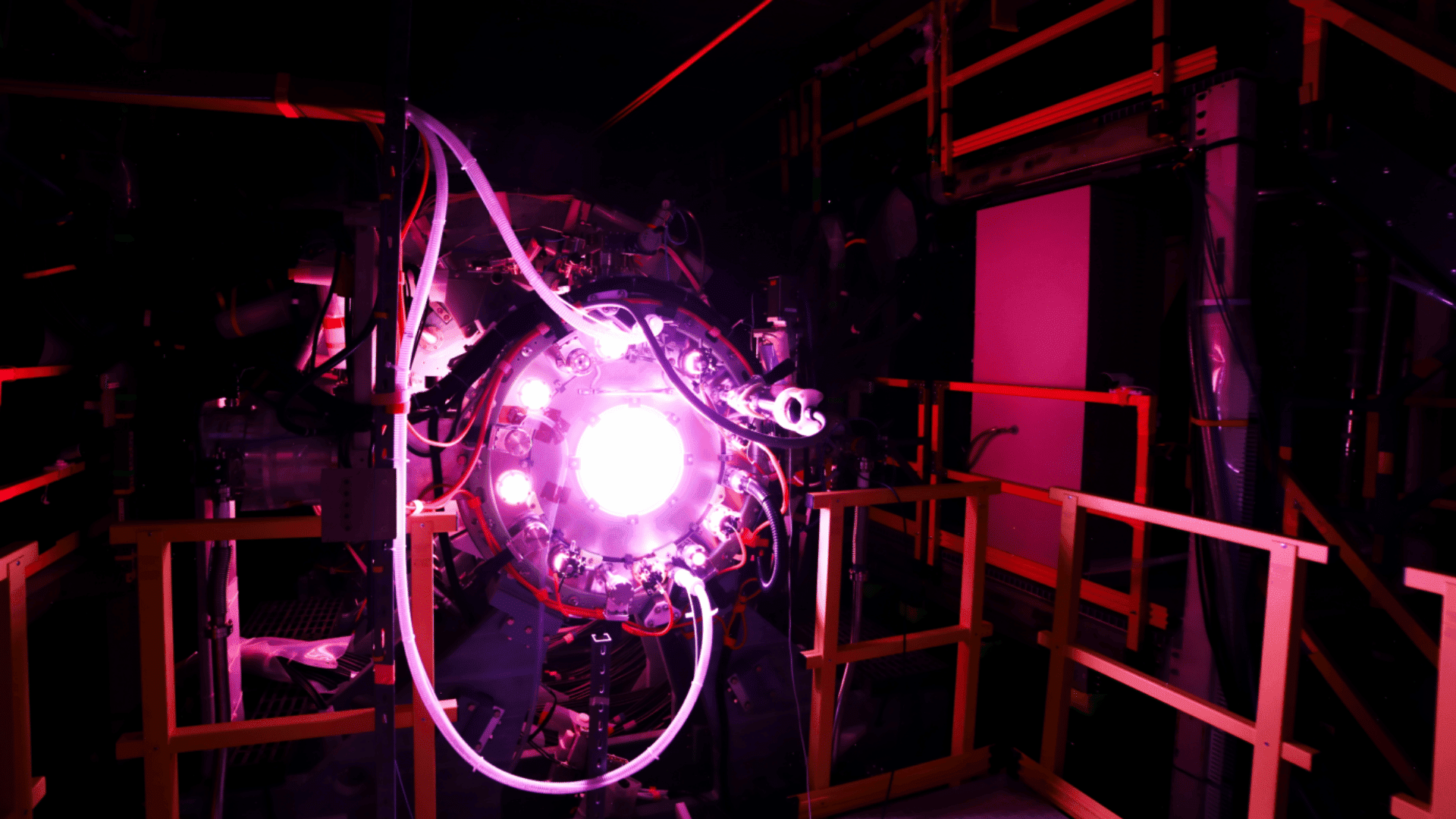

ViBRANT and its control system, called MACS, act as a high-tech dress rehearsal for MARVEL, a real microreactor currently under development. While the “core” is just a light show, the mechanical parts moving the sensors and drums are the exact same ones that will be used in the functional nuclear version.

“MACS/ViBRANT is a hybrid,” Tony Crawford, the researcher who led the project, said. “The actual actuators are the same technology that will be used in the MARVEL reactor.”

“The fuel, the hazardous reflector and absorber materials driving reactor physics are actually replaced by benign materials amenable to light physics,” he added. “It reduces all the hazards from a real reactor to safe and accessible levels with the promise of accelerating development.”

Ability to Adjust

Because the system is safe to stand next to, engineers can adjust the hardware in ways they couldn’t with a live radioactive core. This hands-on approach has already helped the team catch and fix mechanical issues, like a slipping part in the control drums that was redesigned after it failed during a test.

While the real MARVEL reactor might take a full day to reach its operating temperature, the ViBRANT surrogate can be tuned to simulate that entire process in just 10 minutes.

“Ben Franklin once said, ‘Tell me and I forget, teach me and I may remember, involve me and I learn,’” Crawford said. “By being accessible and as intuitive as watching a TV screen, nearly everyone in the reactor development process, from the modeler to the control system developer to the assembler, can get involved and learn.”