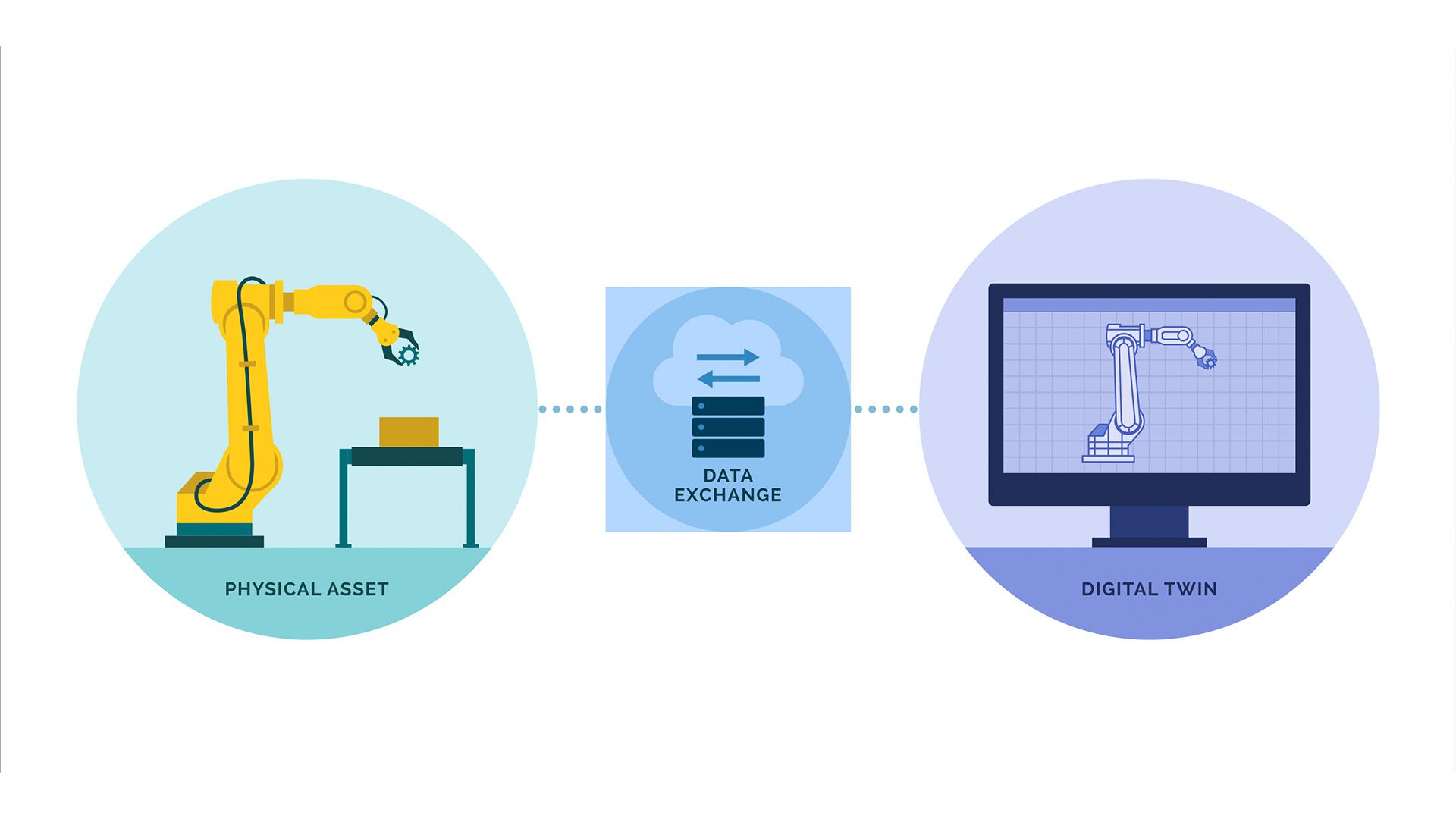

A digital twin uses real-world data to create a virtual replica of any space or object in the physical world. Digital twins have already been proven useful in industries from manufacturing to sports to healthcare, and their global market is expected to reach $48.2 billion by 2026.

How Does A Digital Twin Work?

Digital twins are a combination of multiple enabling technologies; companies decide on which technologies to use depending on their needs. For example, they can use a combination of sensors, cloud computing, AI, AR, VR, and more to experience what the space or object is like firsthand.

Thanks to a network of sensors, the digital twins observe their physical environment to dynamically gather real-time data. The twins learn from the information and its contexts by interacting with humans, devices, and other digital twins. Digital twins can thus support critical decision-making, identify potential issues, optimize and improve systems, and more.

History of Digital Twins

Digital twins were formally introduced by Michael Grieves in 2002 at a conference at the University of Michigan, though NASA was using the concept in the 1960s In the presentation, Grieves’ outlined the concept of a digital twin by discussing real space, virtual space, and the information flow between the two spaces.

Digital twins were not fully embraced or officially named until 2010. NASA used the concept of digital twins to create digital simulations of space capsules and craft for testing. In 2017, Gartner named digital twins as one of the top 10 strategic technology trends, and the concept has been increasingly used ever since. The Internet of Things has since made digital twins more cost-effective and attainable, further popularizing the technology.

Examples & Applications

Because of their customizability and flexibility, digital twins have been used in many different industries and companies for a variety of purposes.

Safety

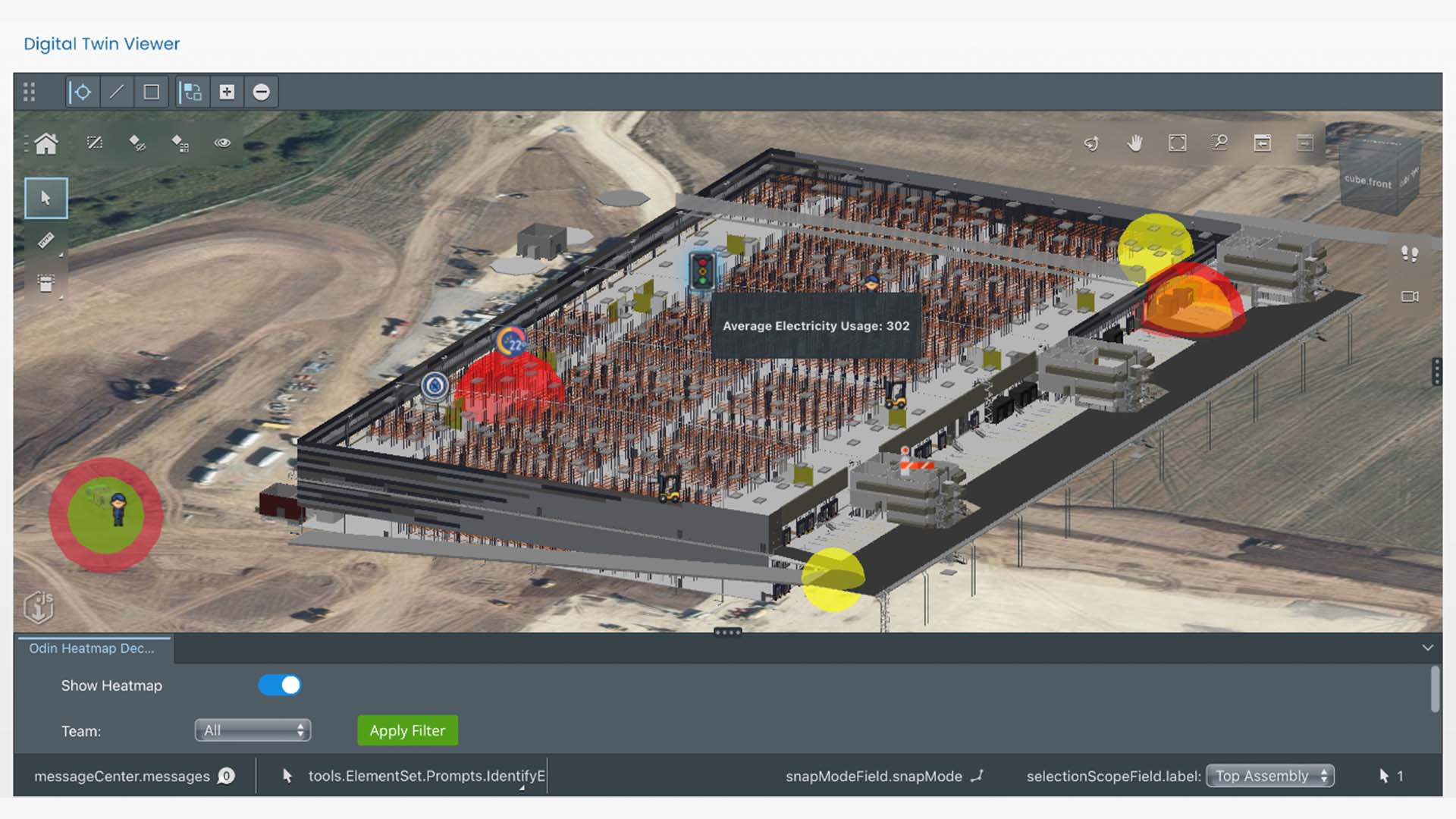

Digital twins replicate physical models, allowing them to keep people out of dangerous locations and predict future problems.

For example, bridge inspectors often suspend themselves with ropes to inspect the tens of thousands of bridges in each state. To save time and reduce risks, drone-based bridge inspections use photogrammetry to create a digital twin. The 3D model produces rapid inspection, detailed analysis, and AI-detected defects, all while keeping inspectors out of danger.

As for predicting future issues, Digital Energy’s ODIN Safety tool, for example, combines digital twin data with AI to predict and avoid potential industrial accidents. After users create an accurate digital twin with reality capture scanning, they can view virtual representations of physical assets within their facility in real time. The data can be fed into AI systems that predict potential hazards and accidents on a job site.

Healthcare

The implications for digital twins in healthcare are massive. For example, they can design medical devices like vena cava filters. To create the filter, researchers need a patient’s digital twin and the medical device’s digital twin. The two models are correlated and researchers can see what happens when the device is installed into a patient’s body without any medical tools, surgery, or side effects.

Similarly, the Living Heart Project is developing highly accurate personalized digital human heart models based on MRI images and ECG data. By leveraging the digital twin heart, researchers can simulate in-vivo (in a living organism) conditions, visualize unseen anatomy, and refine the designs of cardiological devices faster.

City Planning

By 2050, 70 percent of the world’s population is predicted to live in urban cities. This means that cities will likely continue to struggle with the consequences of rapid population growth such as air pollution, traffic congestion, and inequality.

One possible solution to address city design and sustainability issues is digital twins. By combining traditional 2D and 3D urban planning tools with digital twin technology, dynamic virtual models on the city scale can be created. The virtual models enable planners to run simulations of different scenarios in construction, traffic, energy consumption, and more to determine possible outcomes without having to make any actual changes.

For example, Chattanooga, Tennessee, built a digital twin to anticipate and alleviate traffic congestion relief. Researchers ran digital twin experiments on one street in the city and found that more than 90 percent of cars get stopped by red lights during the midday rush. As a result, the city recomputed the timing for traffic signals along the road to change their signaling pattern every four minutes based on traffic conditions. Thanks to digital twin technology, the city will be able to reduce traffic congestion by up to 30 percent.

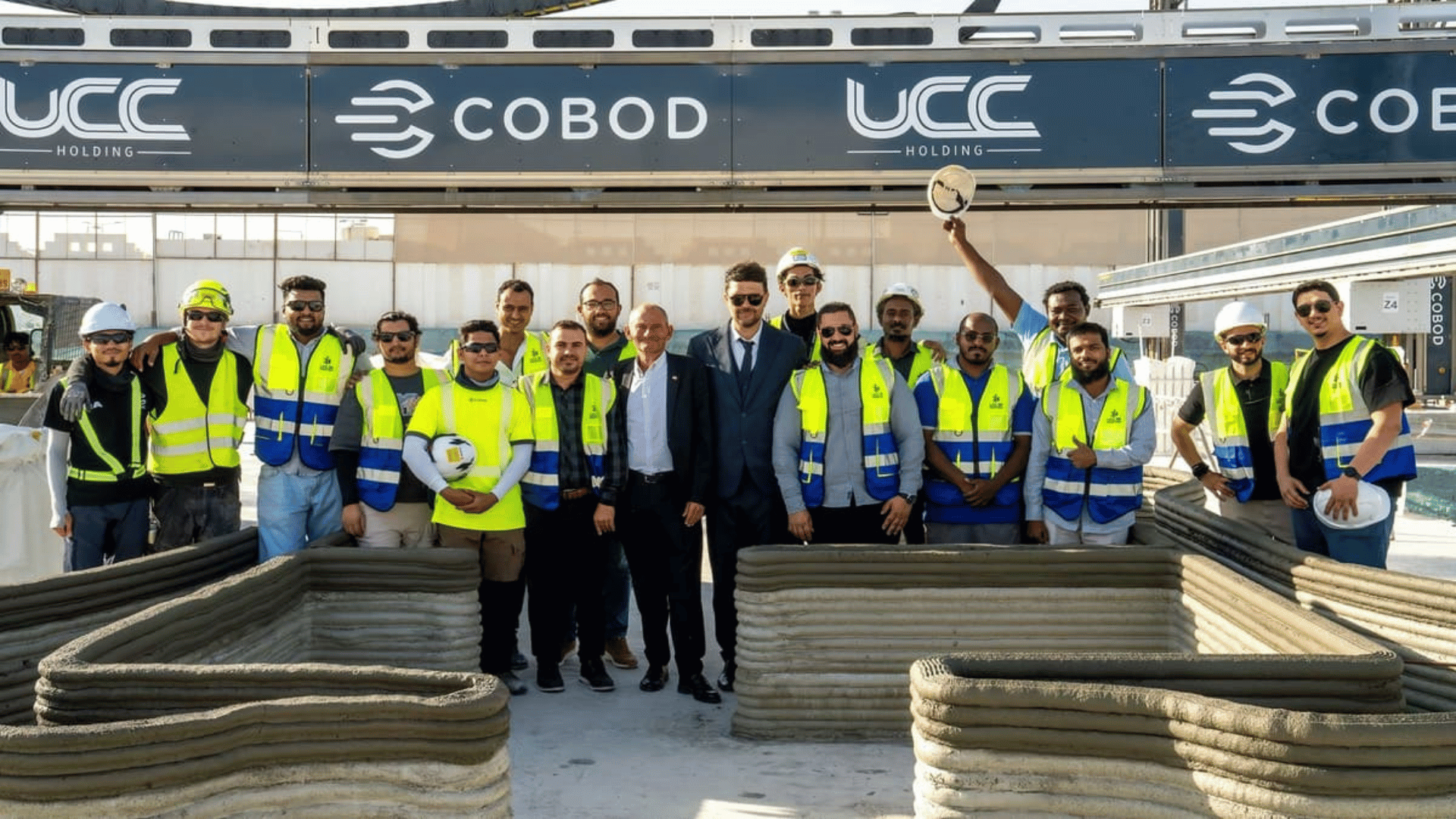

Manufacturing

Some companies are using digital twins to make the production process more efficient and flexible. For example, Unilever PLC, a multinational consumer goods company, created virtual models of its factories, hosted on Microsoft’s Azure platform.

The IoT sensors provide real-time performance data, such as temperature and motor speed, which is combined with advanced analytics and machine learning algorithms to identify the best operational conditions. This helps manufacturers become more sustainable by limiting waste from products and using materials more precisely. Unilever is currently operating eight digital twin factories across four continents.

Architecture

Digital twins can be used in architecture to improve efficiency and safety. For example, TK Elevator, in collaboration with Microsoft Azure, used a digital twin to create the world’s first rope-less elevator for a high-rise building.

In the development stage, the digital twin simulated different situations, like testing emergency brakes, that would have been costly and time-consuming in the physical world. During operation, the elevator now has over 100 sensors per meter that continuously collect data for its digital twin. This data is sent to the Microsoft Azure digital cloud to look for anomalies, predict future failures, produce insights for troubleshooting, and more.

The rope-less elevator improves efficiency because it allows an elevator to go as high up as possible while using less shaft space. This will allow for more people to fit in high-rise buildings in a more spacious way. And, thanks to the digital twin, the elevator will be completely safe.

For more information on digital twins, check out everything you should know about digital twins, Singapore’s digital replica, the digital copy of Ancient Olympia, and how the NFL uses digital twins.

For more information on how TK Elevator used Microsoft Azure’s digital twin program, we visited the TK Elevator Test Tower in Germany. Check it out: