Explore Tomorrow's World From Your Inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

Every summer, you can’t wait for the weather to warm up so you can slip on your swimming trunks or bathing suit, put on your favorite pair of shades, and spend a pleasant afternoon cooling off at your local pool. But have you ever wondered how a swimsuit is made and how it came to be?

The Evolution of Swimsuit Production

The first bathing suits were invented in the eighteenth century. Men typically swam without a suit, and women’s suits were designed to be modest with loose, long gowns. The women’s suits were made out of linen, wool, canvas, or flannel, and they often had small lead weights sewn into the dress to ensure that the dress did not float up in the water.

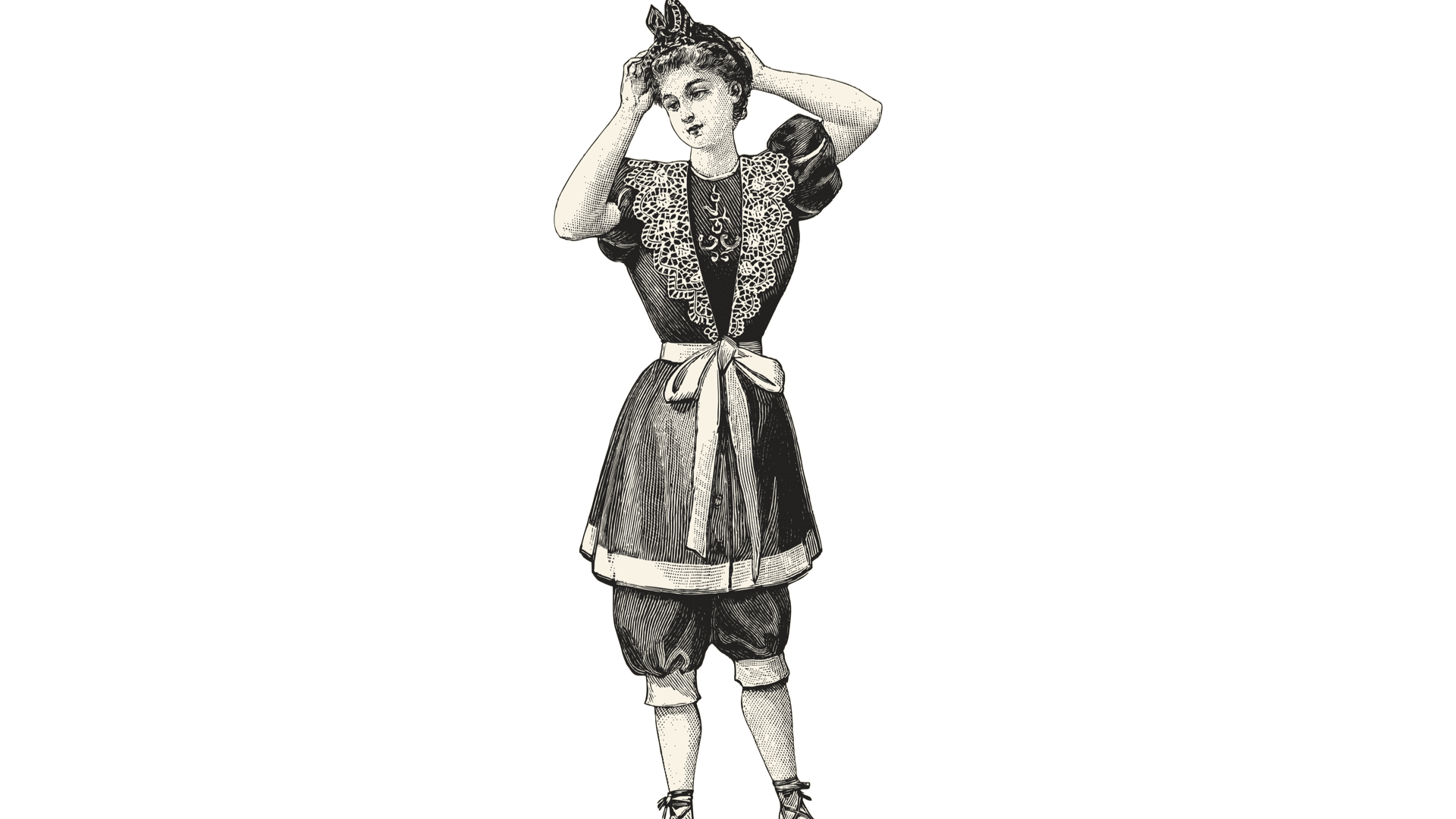

In the 19th century, swimsuits remained modest but were a bit more fitted, consisting of bathing dresses, drawers, and stockings for women, and bloomers, overblouses, and stockings for men. These suits were still wool or cotton.

Swimsuits began revealing swimmers’ legs in the 20th century. The swimsuits were still woolen knit for the general population, but affluent people could afford the trendy silk jersey swimming suits.

It wasn’t until latex yarn was invented in 1931 that swimsuits as we know them today began taking form. The latex was combined with artificial fibers such as rayon, which resulted in a stretchy and shiny fabric. Following this, synthetic materials such as Dacron, Lycra, and Spandex were invented and used in the making of swimsuits. These materials allowed bathers to be more flexible while swimming and let manufacturers be more creative, leading to innovations like the bikini in 1946. Throughout the second half of the 20th century, swimsuits became even more flexible with the help of synthetics like polyester, acrylic, and nylon, adding the necessary quick-drying properties which we now wear.

Today, the production of swimsuits has become so advanced that certain materials have even been banned from swimming competitions. In 2009, the International Swimming Federation (FINA) set forth regulations for swimsuits to fall within certain limits of thickness and buoyancy. This was in reaction to the use of the Speedo LZR polyurethane swimsuit used in the 2008 Beijing Olympics. It was discovered that 94% of swimming races that were won in these Olympics were won in LZR suits. The suits’ panels reduce muscle vibration, improve buoyancy, and minimize drag. In 2010, FINA prohibited the use of all non-textile swimsuits for use in competition, with a particular focus on polyurethane.

How Swimsuits Are Made Today

1. Materials Weaved & Colored

Following this rich history of the production of swimsuits, today’s manufacturing process is fairly similar for all swimsuits on the market. The process begins with loading spools of cotton and synthetic thread onto knitting machines, which weave threads into rolls of fabric. Afterward, the rolls are fed into a large tank where pre-measured concoctions of bleach and colored dyes are then released into the tank and stirred. After the fabric reaches the desired color and is cleared, it is then sent to dry and stored until it is time to make your bathing suit.

2. Fabric Measured & Cut

When the fabric is ready to be used, a worker will bring it to a measuring table and they use an encoder to measure and cut it into smaller pieces. It is then taken to another station where computerized machinery cuts out the swimsuit pieces from the smaller lengths of fabric. The number of pieces cut at this step depends on the type of swimsuit design. For example, a one-piece swimsuit will require two pieces to be cut (the front and back sides) whereas a two-piece swimsuit will be cut into four sections.

3. Pieces Sewn & Pressed

The swimsuit pieces are then taken to individual seamstresses for them to be sewn together using industrial sewing machines. Depending on the swimsuit style, this is also the stage of manufacturing where the bra cups are sewn into the design using two small strips of fabric and a strategic sewing pattern.

If the design includes straps, lengths of elastic are placed between two strap pieces, and the three pieces are sewn together. The straps are then either sewn onto the suit or attached using a hook design in which two small pieces are sewn on for the removable strap option. The finished pieces are pressed, labels are added, and then they’re ready to go from manufacturer to making waves.

Explore the World of Production, and discover how life jackets, sunglasses, and game controllers are made.