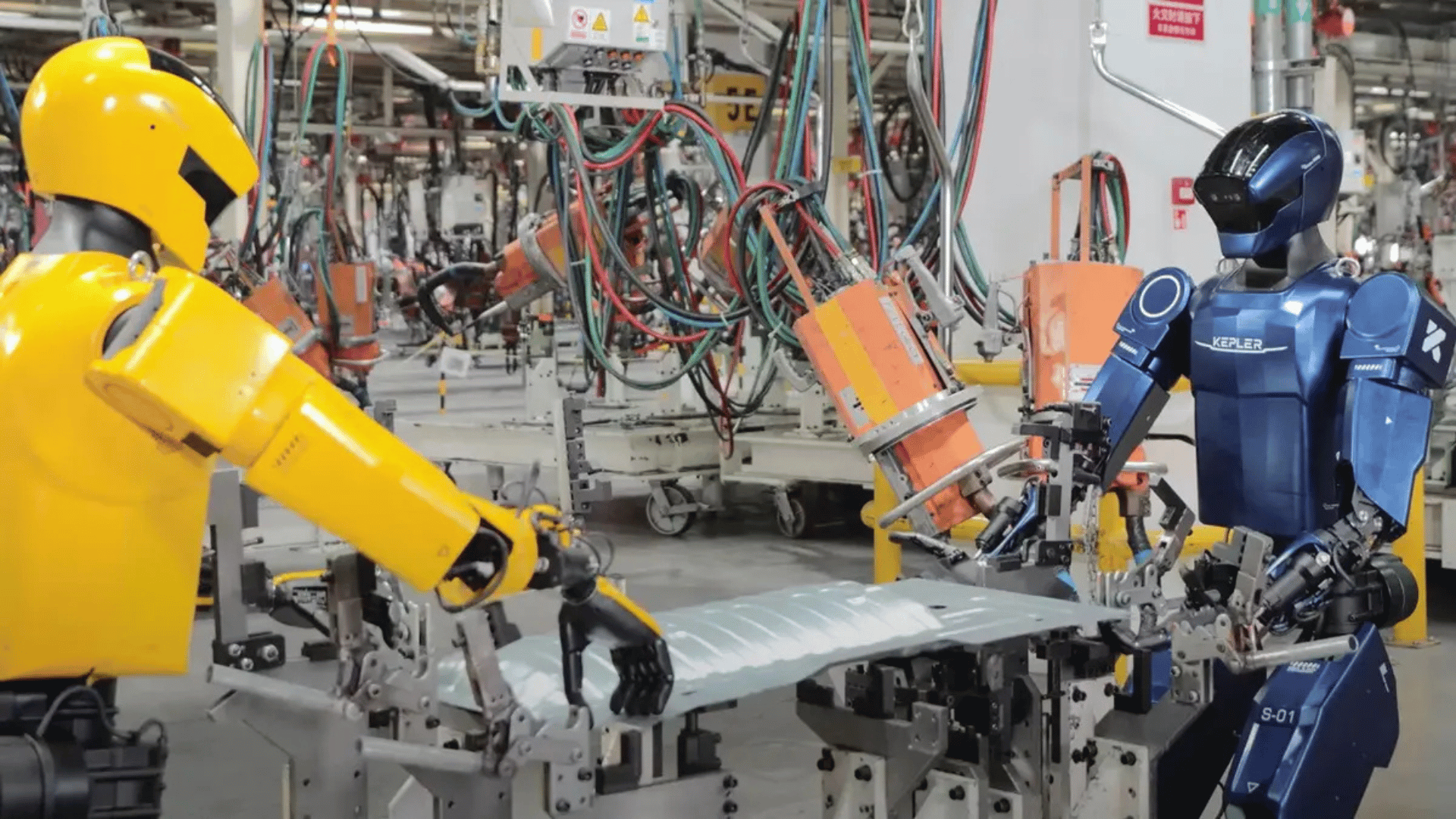

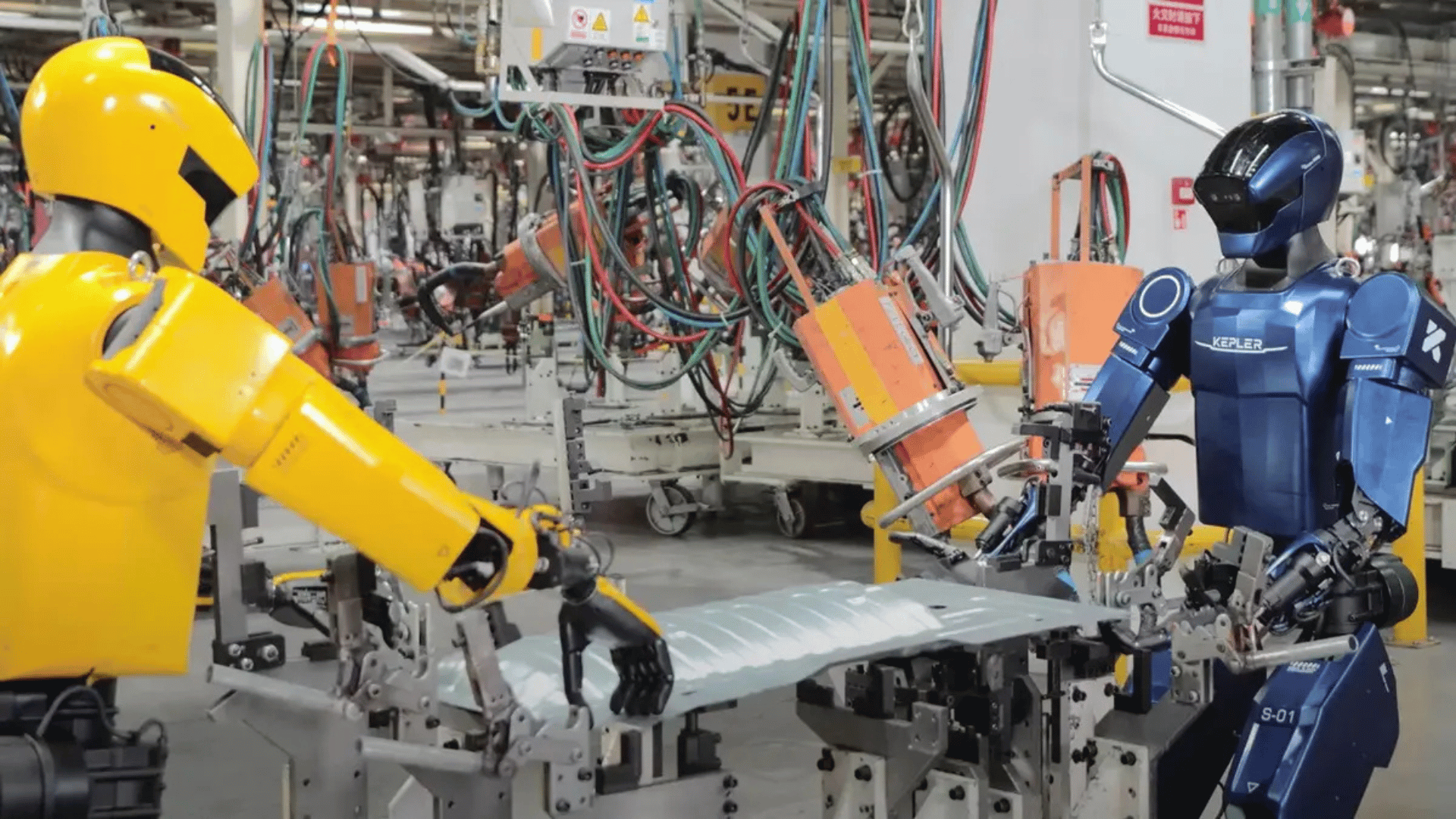

A humanoid robot called Forerunner K2 is showing off its skills by assembling car parts and conducting quality checks at a SAIC-GM automotive plant.

Kepler’s Forerunner K2

Kepler showed off its K2 robot in a video released on YouTube, marking the firm’s first step toward testing this model across various industries. Some industries are already taking steps toward integrating similar models into their production lines, including BMW, which has incorporated Figure’s humanoids into its production lines at the Spartanburg plant in South Carolina.

The new video showcases Kepler’s Forerunner robots assisting with automotive manufacturing by handling heavy and large components, manipulating mechanical fixtures, navigating factory environments, autonomously loading stamped parts, and performing quality inspections. The variety of tasks showcases how K2’s abilities range from heavy operations to precision tasks.

Advertisement

As Kepler’s most recent humanoid robot model, the Forerunner K2 improves on the K1 model in task planning, full-body coordination, perception, and autonomous learning by integrating cerebral, cerebellar, and high-load bodily functions. The robot’s embodied control system and cloud-based cognitive model allow it it accomplish tasks on its own.

The humanoid’s 2.33 kWh battery allows it to operate for up to eight hours continuously. According to Kepler, the tactile manipulators now support 11 degrees of freedom per hand and a 33-pound load capacity.

In the manufacturing industry, these robots contribute to automated production lines by conducting assembly, quality inspections, and predictive analysis using cloud-based data tools. The firm asserted that the K2 can identify design flaws, thereby ensuring product quality and consistency.

According to Kepler, the K2 models are built to ensure durability, waterproofing, and temperature resistance to ensure its capable of operating in outdoor or otherwise hazardous areas, including radiation zones or explosive environments.

The company claims its humanoid robots are made for industries such as security, research, manufacturing, logistics, education, and outdoor operations.