The rapid acceleration of artificial intelligence has pushed the boundaries of computing, leading to new generations of silicon that are significantly more powerful and significantly hotter than their predecessors. This thermal challenge threatens to “put a ceiling on progress in just a few years,” according to a recent report from Microsoft detailing a “critical” infrastructure breakthrough.

Current data center cooling technology, primarily cold plates, struggles to keep pace with the heat output of advanced AI chips. Sashi Majety, senior technical program manager for Cloud Operations and Innovation at Microsoft, warned that in as few as five years, “if you’re still relying heavily on traditional cold plate technology, you’re stuck.”

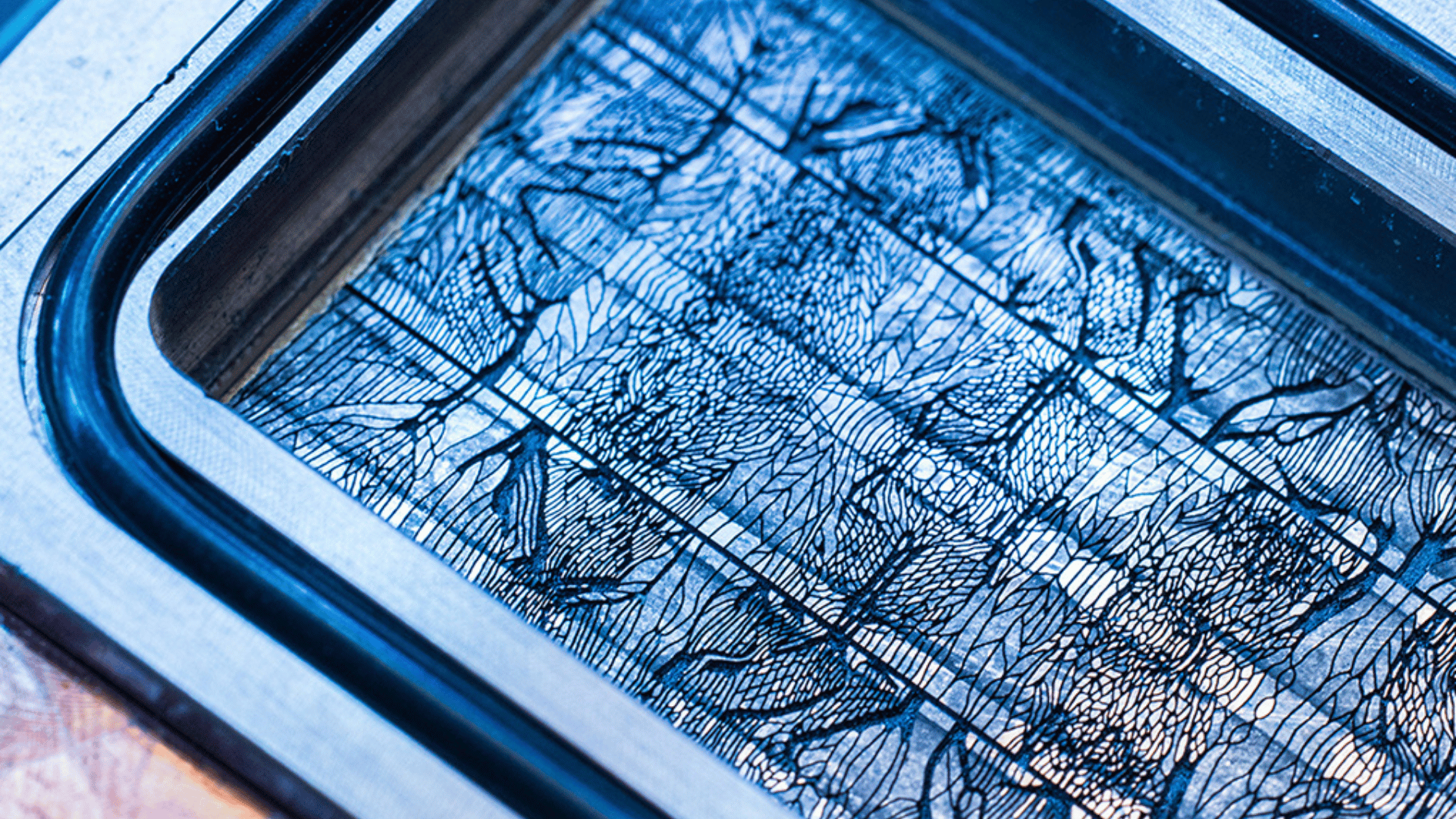

To overcome this impending bottleneck, Microsoft has developed a new in-chip microfluidic cooling system, introducing a new era of thermal management. The technique utilizes microfluidics, which involves etching tiny, human hair-sized channels directly onto the back of the silicon chip.

This allows liquid coolant to flow directly onto the heat source, maximizing efficiency. Microsoft’s lab-scale tests showed that microfluidics removed heat up to three times more effectively than cold plates, depending on the workload, and reduced the maximum temperature rise of the silicon inside a GPU by 65 percent.

Microfluidics and AI to Cool Future Chips

Beyond raw performance, the new system offers significant benefits for data center design and sustainability. Judy Priest, Corporate Vice President and Chief Technical Officer of Cloud Operations and Innovation at Microsoft, said, “Microfluidics would allow for more power-dense designs that will enable more features that customers care about and give better performance in a smaller amount of space.”

The team also expects the technology to improve Power Usage Effectiveness (PUE) and reduce operational costs.

The successful implementation required complex engineering and system-level thinking, according to Microsoft. As part of the prototyping effort, Microsoft collaborated with Swiss startup Corintis, utilizing AI to optimize a bio-inspired design for microchannels that resembles the veins in a leaf. This design proved more efficient at cooling “hot spots” than simple straight channels.

The engineering challenge also required designing a leak-proof package, testing various etching methods, and determining the optimal coolant formula without compromising the silicon’s integrity.

This cooling breakthrough is part of a larger investment by Microsoft in next-generation infrastructure, including the development of its own Cobalt and Maia chips.

Looking ahead, Jim Kleewein, Technical Fellow at Microsoft 365 Core Management, added, “Microfluidics improves each of those: cost, reliability, speed, consistency of behavior, sustainability.” Microsoft stated that it will continue to work with fabrication and silicon partners to bring microfluidics into production across its global data centers.