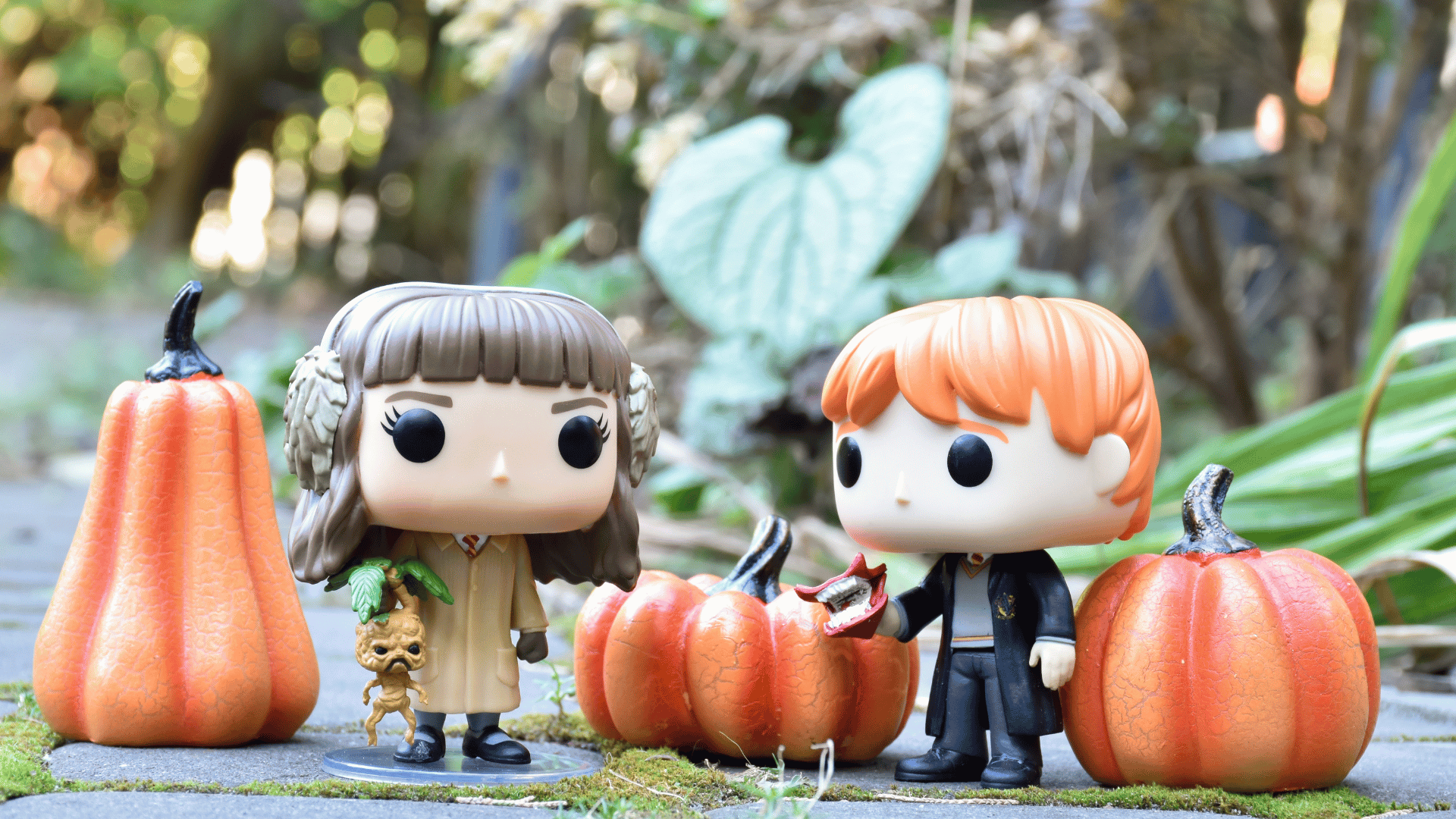

Ever wondered how your favorite Funko figures come to life? From the spark of inspiration to the moment you unbox that iconicly styled collectible, each Funko Pop undergoes a creative journey fueled by imagination and innovation. In this behind-the-scenes look, we Pop! over to the Funko factory to explore the design process through the lens of Tomorrow’s World Today’s four worlds.

Inspiration

The Funko production process begins with a strike of inspiration, which, according to Funko VP of Creative Ben Butcher, can come from anywhere.

“The unique thing about the process here is it can start from anywhere. People who have been here for as little as two weeks can have an idea and get it going. We take the time to listen to the passion of our people. Even if leadership hasn’t heard about it, we’ll take the time to look into it.” Butcher stated.

Creation

Once they’ve selected the character they want to spotlight and obtained the necessary licensing, sculptors work digitally with rough sketches and concept models to determine the optimal design and proportions. They also ensure that the design’s dimensions can fit within standard Funko packaging.

“As we start a project, everyone on the team works together to review the character and their size in that world; are they a full-grown adult, a young child, or a massive behemoth monster? There are also cases when a character doesn’t fit into those usual categories. We work together and discuss the different proportions. That then drives forward the concept artist and sculptor to plan all the proportions, in line with the set standard of past figures,” stated Ryan Frost, Funko Sculptor.

Innovation

After the initial design is complete, the character file is sent to a manufacturing partner for 3D printing of the prototype. The physical prototype and detailed digital images are reviewed to ensure the prototypes match the design. Factors such as design symmetry and balance ability are also considered at this stage, prior to the figure’s final approval.

“Thankfully, there are very convenient sizing-check tools included in the program we use that allow us to make sure our figures don’t 3D print out at 10 feet tall or 1 inch! Sizing is one of the most important steps of our process as everything revolves around the average height of 3.74″, roughly, for Pops! and various sizes for our other figure lines. But we also all use math to build on top of each team member’s role in order to get the final figure you see on your shelf!” stated Ryan Frost, Sculptor.

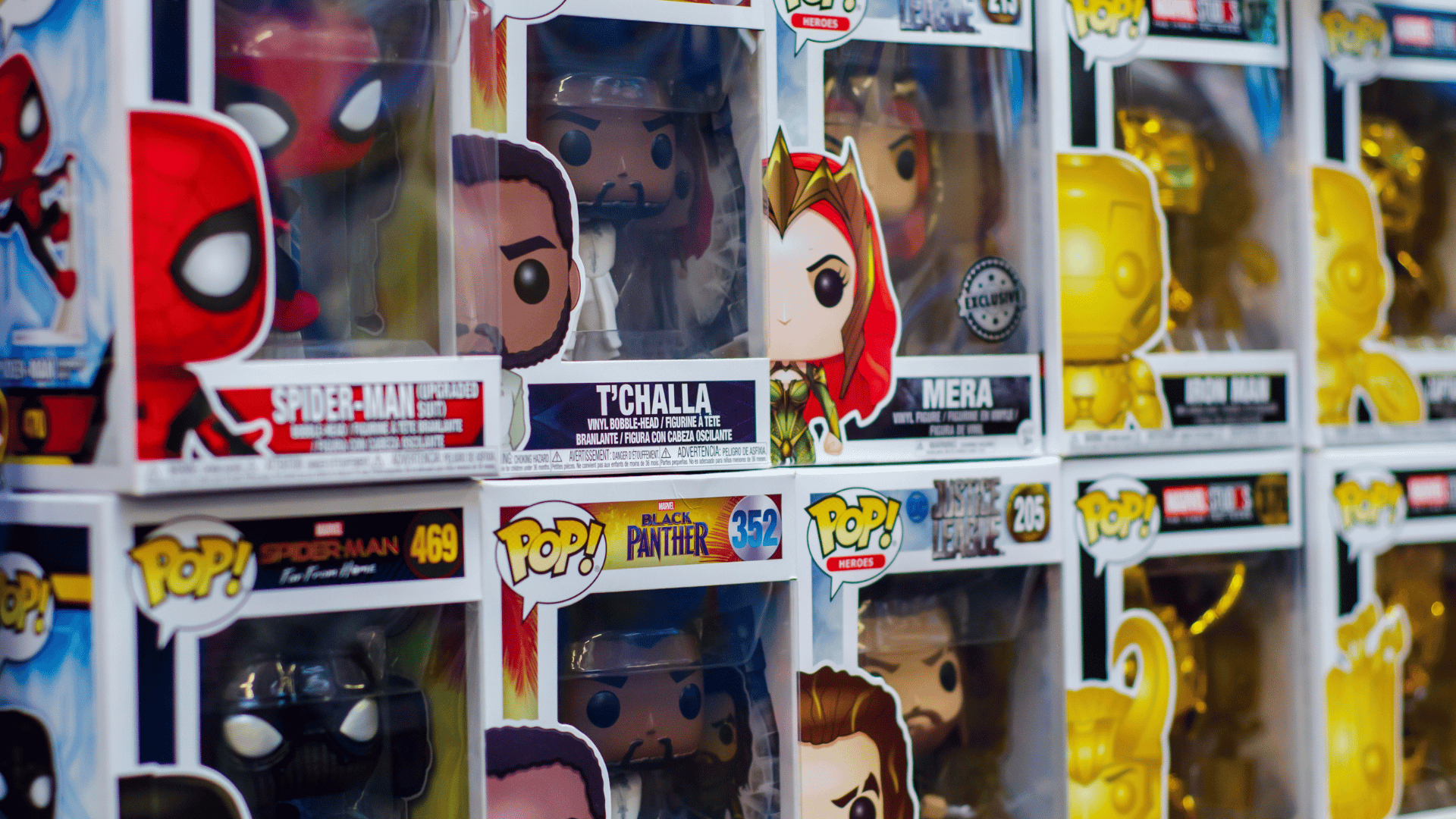

Production

The figure is then scheduled to run by the firm’s manufacturing facility. Funko engineers help to determine what materials should be used and how figures should be sculpted to make them moldable. This is also the stage where figure designers finalize packaging and paint schemes, also known as “deco” or “paint ops”. The size of the production run depends primarily on market research.

“There’s a lot that goes into Pops! that might not be so obvious at first glance. We have to consider how they are made and what materials are used so they can be produced. Different plastics have different properties and choosing the right ones can mean the difference between success and failure. Figuring this stuff out at the beginning of a project, saves time, money, and gives us the most control to make the final product look like the characters we love.” stated Mo Flint, Sr. Toy Sculptor.

Tune in to Science Channel to watch “Toy Treasures” at 10 AM ET on Saturday, October 1st!