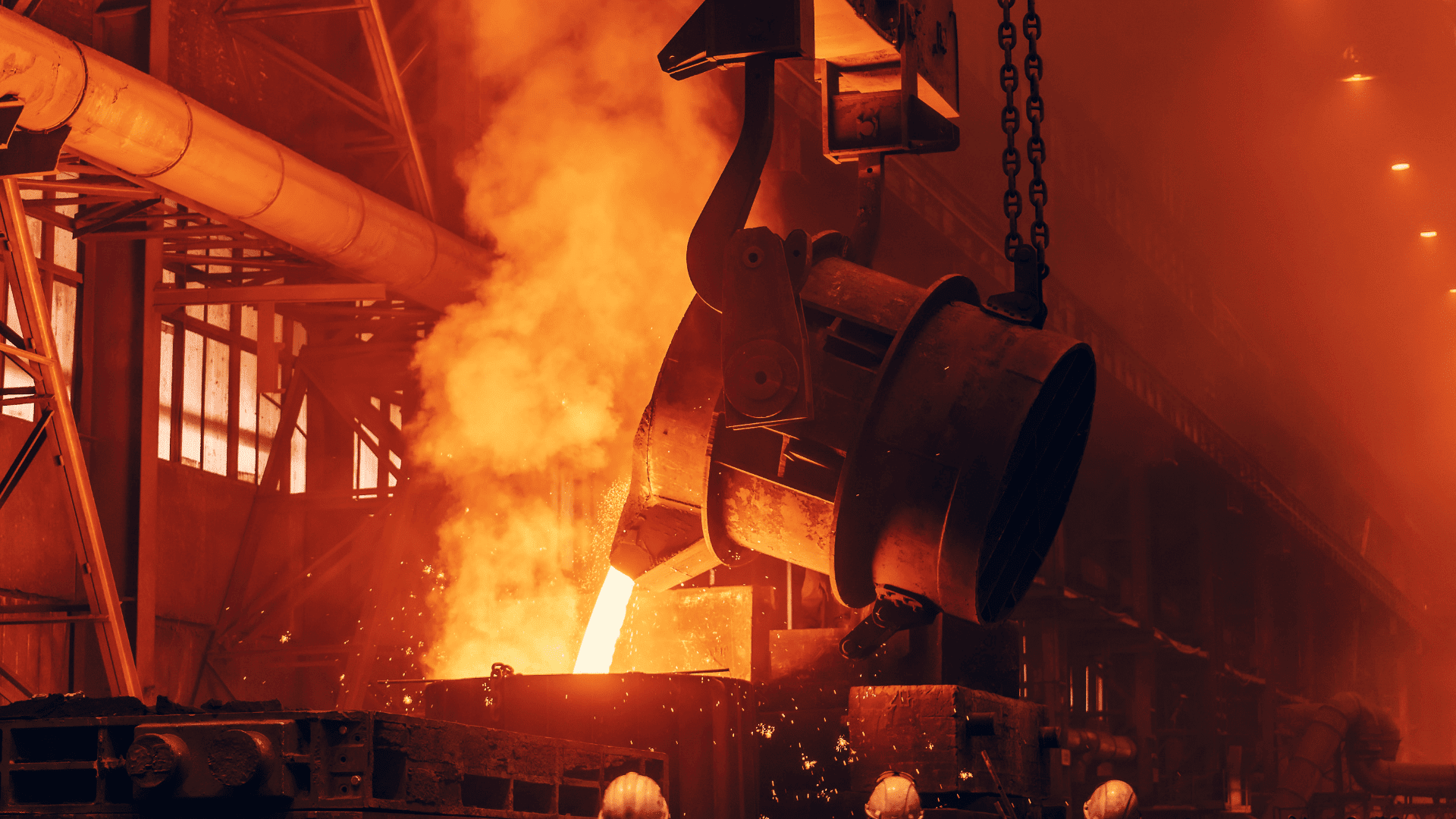

Wastewater sludge is a by-product of water treatment. This sludge is typically dried and then burned or dumped. However, European Union researchers believe there is a different way to dispose of the sludge. They see the by-product as a valuable resource. Researchers see the sludge not as a problem but as a key player in green steel production.

Their concept is central to the H2STEEL research initiative, which aims to decarbonize one of the world’s most polluting industries.

Wastewater For Green Steel Production

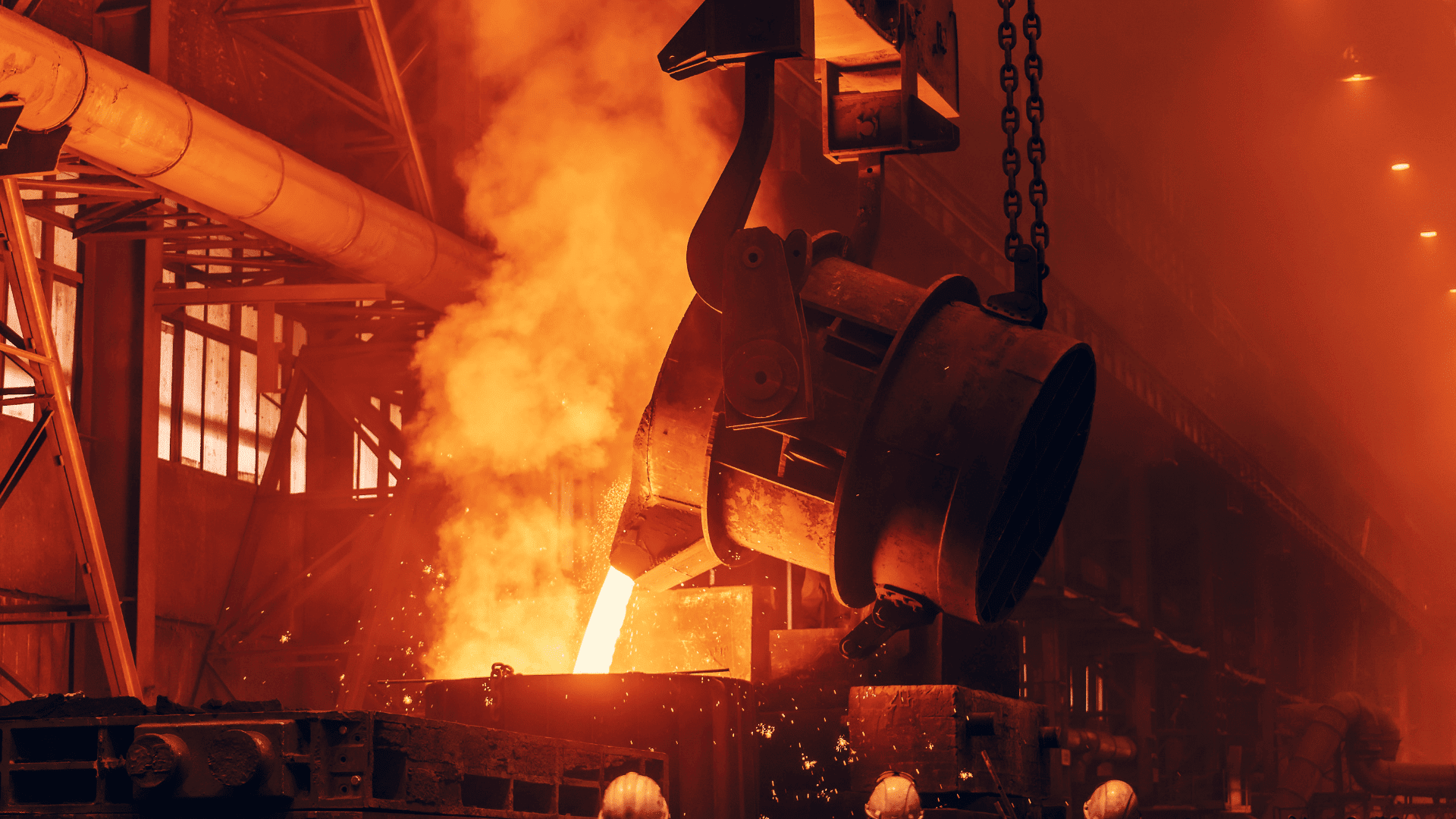

While steel production is vital for infrastructure, it currently accounts for 8% of global CO2 emissions, according to the International Energy Agency. A significant factor behind the staggering number is the steelmaking industry’s need for carbon-rich ingredients. As a result, it’s one of the most difficult and costly industries to go green.

The H2STEEL project proposes a circular approach.

“This sludge has value, it is not just waste,” said David Chiaramonti, the project lead and professor of energy systems at the Polytechnic University of Turin. “With it, we can create things like carbon and hydrogen.”

Advertisement

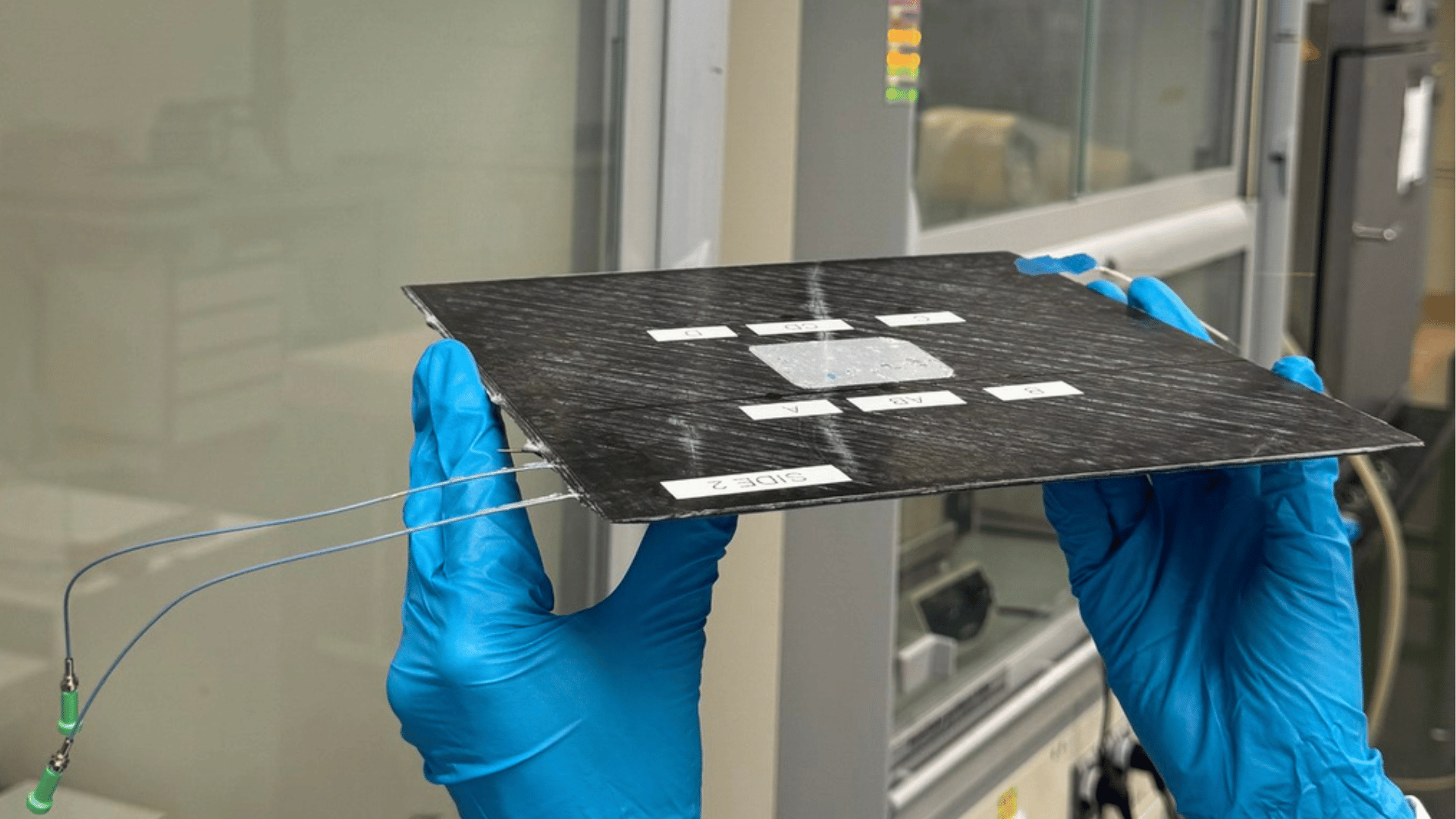

Their approach is designed to extract hydrogen and a carbon-rich material called biocoal from wastewater sludge. These two components are crucial for cleaner steel production.

First, the wastewater sludge goes through a process called “carbonization.” During carbonization, the sludge is heated without oxygen to create biocoal. Then, the biocoal acts as a catalyst to process methane from biogas plants, which produces hydrogen.

“We break the biomethane into carbon and hydrogen by using the carbonized sludge at 900°C,” Chiaramonti said. “That’s how we turn it into biocoal and circular hydrogen.”

Traditionally in steel production, coal is burned with iron ore, which releases a vast amount of CO2. However, with H2STEEL, hydrogen can replace some of the coal, and the biocoal substitutes regular coking coal.

Fast and Flexible

According to researchers, the technology is attracting industry interest, including the world’s second-largest steel producer, ArcelorMittal. Jan Wiencke, team leader for sustainable carbon at ArcelorMittal, said, “Whether we use a hydrogen furnace or an electrical one, we will still need ingredients like carbon and hydrogen in our processes.”

Additionally, H2STEEL’s speed is a significant advantage. If the current trials, which are scheduled to conclude in March 2026, are successful, the technology could be rolled out quickly. Typically, infrastructure changes in an industry often take decades. However, challenges include securing a sludge supply chain and proving the technology’s economic viability. “This is a great technology for the steel industry, but it must prove itself economically,” Wiencke concluded.