Researchers at Drexel University have developed a new method that uses ultrasound to help manufacturers detect defects in batteries before they become dangerous.

Ultrasound Tech Detects Battery Issues

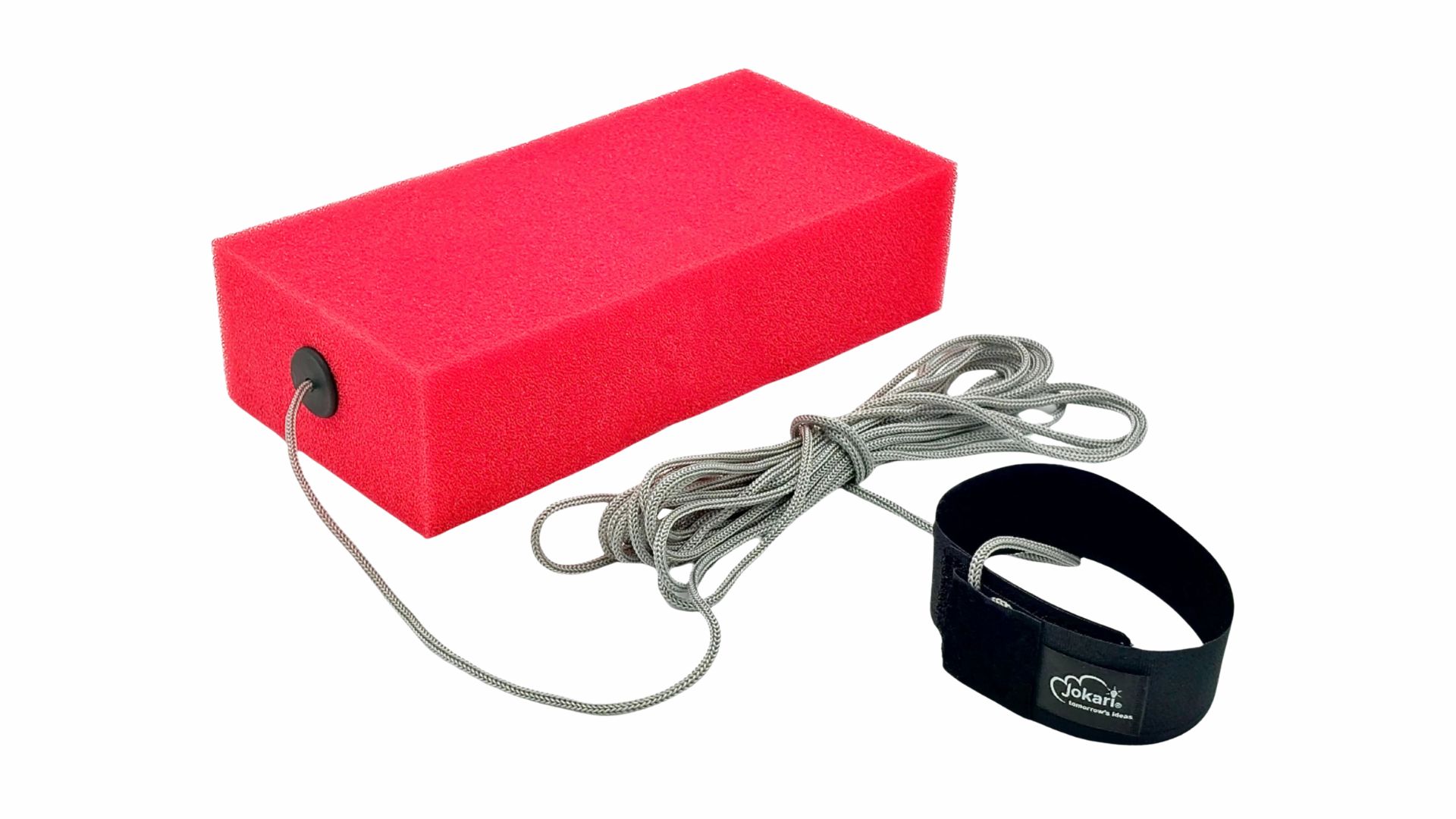

The team used ultrasound technology to build a benchtop diagnostic tool that offers a low-cost and quick means of finding internal issues in lithium-ion batteries. The technique could allow faster identification of structural flaws such as overheating or thermal runaway.

According to Interesting Engineering, the team used scanning acoustic microscopy to send low-energy sound waves through commercial pouch cell batteries. The waves changed speeds as they passed through various materials, revealing the internal structure and mechanical features without disrupting the battery’s function.

“By observing how the sound wave has changed upon interacting with the sample, we can deduce a number of structural and mechanical features,” the researchers wrote.

Battery manufacturers currently rely on X-rays to check parts, which can be expensive, slow, and only reveal a limited amount of information. This new technique can detect dry areas, internal cracks, gas buildup, and misaligned components.

“While the vast majority of lithium-ion batteries today are high performing and safe, defects are bound to exist when thousands of cells are used within electric vehicles and there are millions of electric vehicles being produced every year,” said Dr. Wes Chang, lead researcher and assistant professor at Drexel.

Chang’s team partnered with SES AI, a lithium metal battery startup, to test the tool in a real-world R&D setting. Engineers used the results to refine their designs.

The study is published in the journal Electrochimica Acta. The team plans to make internal flaws even easier to find by allowing three-dimensional imaging of both electrodes and entire cells.

“We hope that by lowering the barrier to entry, ultrasonic testing can become a routine part of battery research and development,” said Chang.

He added, “Battery scientists want to build better batteries, not develop new tools. We provide a user interface that is easy to use with regular software updates.”