Liangbing Hu, a materials scientist at the University of Maryland, created a process that turns ordinary wood into a material stronger than steel. That process will soon be mass-produced by the startup InventWood.

Wood Stronger Than Steel

“All these people came to him,” said Alex Lau, CEO of InventWood, in an exclusive TechCrunch interview. “He’s like, OK, this is amazing, but I’m a university professor. I don’t know quite what to do about it.”

Hu spent a few years perfecting the technology, working to reduce the time it took to create the material from a few weeks to a few hours. Once the product was ready to commercialize, he licensed it to the startup, InventWood, to be mass-produced.

“Right now, coming out of this first-of-a-kind commercial plant — so it’s a smaller plant — we’re focused on skin applications,” Lau said. “Eventually we want to get to the bones of the building. Ninety percent of the carbon impact from buildings is concrete and steel in the construction of the building.”

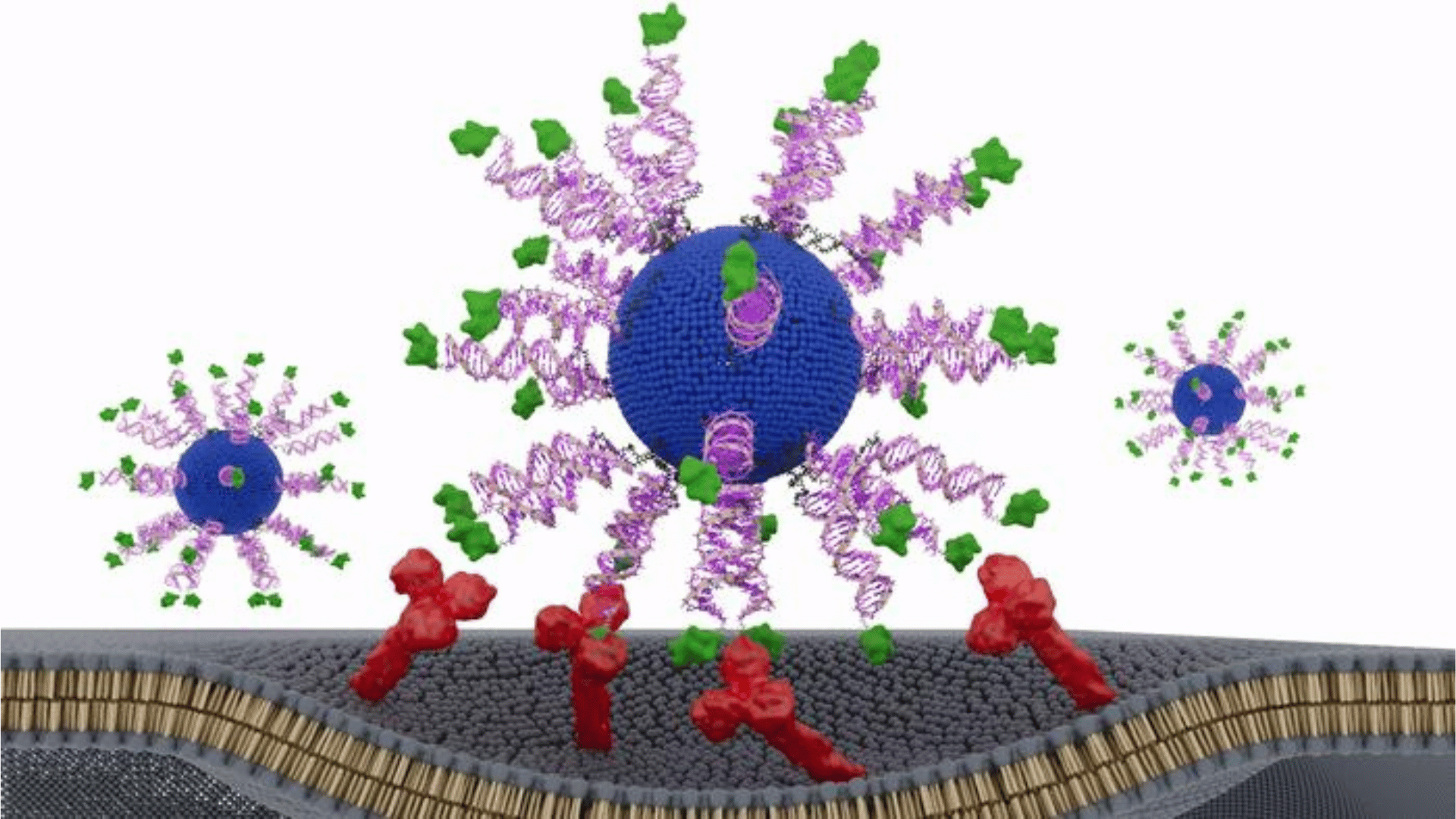

The Superwood product begins with regular timber, which is primarily comprised of cellulose and lignin. The process strengthens the cellulose naturally present in wood by treating it with “food industry” chemicals that modify its molecular structure. The result is compressed to increase the hydrogen bonds between cellulose molecules.

“We might densify the material by 4x and you might think, ‘Oh, it’ll be four times strong, because it has four times the fiber.’ But it’s actually more like 10 times stronger because of all these extra bonds that get created,” Lau said.

The resulting material reportedly has 50% more tensile strength than steel, with a 10 times better strength-to-weight ratio. It’s also highly resistant to fire, pests, and rot. It can also be stabilized for outdoor use on decking, siding, and roofing with some polymer implemented.

“We’ve spent years perfecting our molecular reconfiguration process to maintain the extraordinary properties demonstrated in the lab, while making the process commercially viable,” Lau stated to Fast Company via email.

The process of compressing the material also concentrates the colors, which means it can be used to create strong structural beams that won’t need finishing. Inventwood’s first products will be interior finishes for commercial and high-end residential projects, with exterior-grade panels for siding and roofing planned for later this year.

The firm’s first facility will reportedly produce one million square feet of Superwood annually beginning this summer. The company plans to create structural beams and columns within a few years.