ETH Zurich created a new high-speed, multi-material metal 3D printer that researchers say could change the future of manufacturing. The research team consists of six undergraduate students. Developed as part of their Focus project called RAPTURE, the machine can process several metals simultaneously without the pauses found in traditional printers.

Researchers believe the technology is promising and could significantly cut production time and costs, especially for the aerospace industry.

Advancing 3D Printing Technology

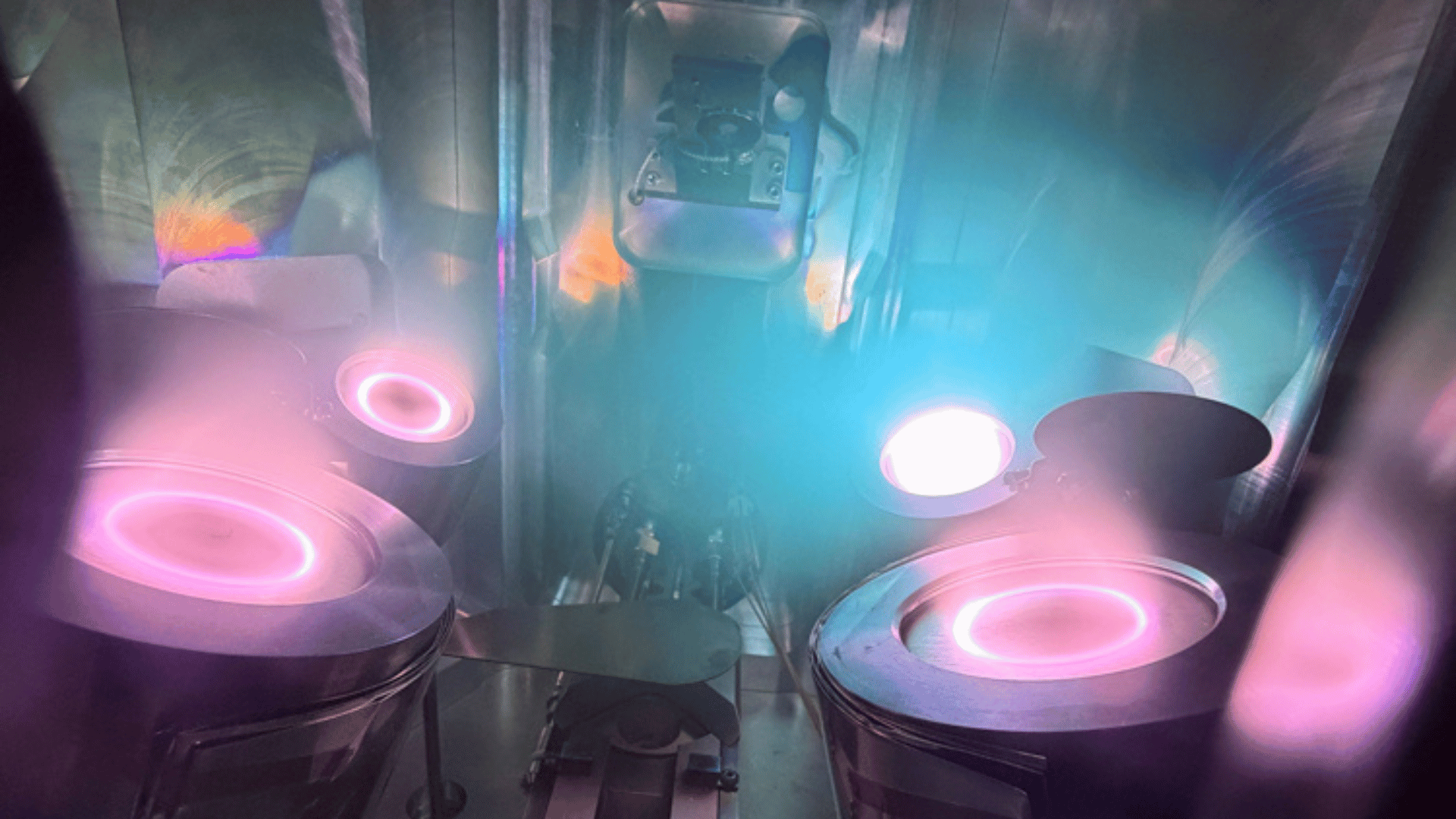

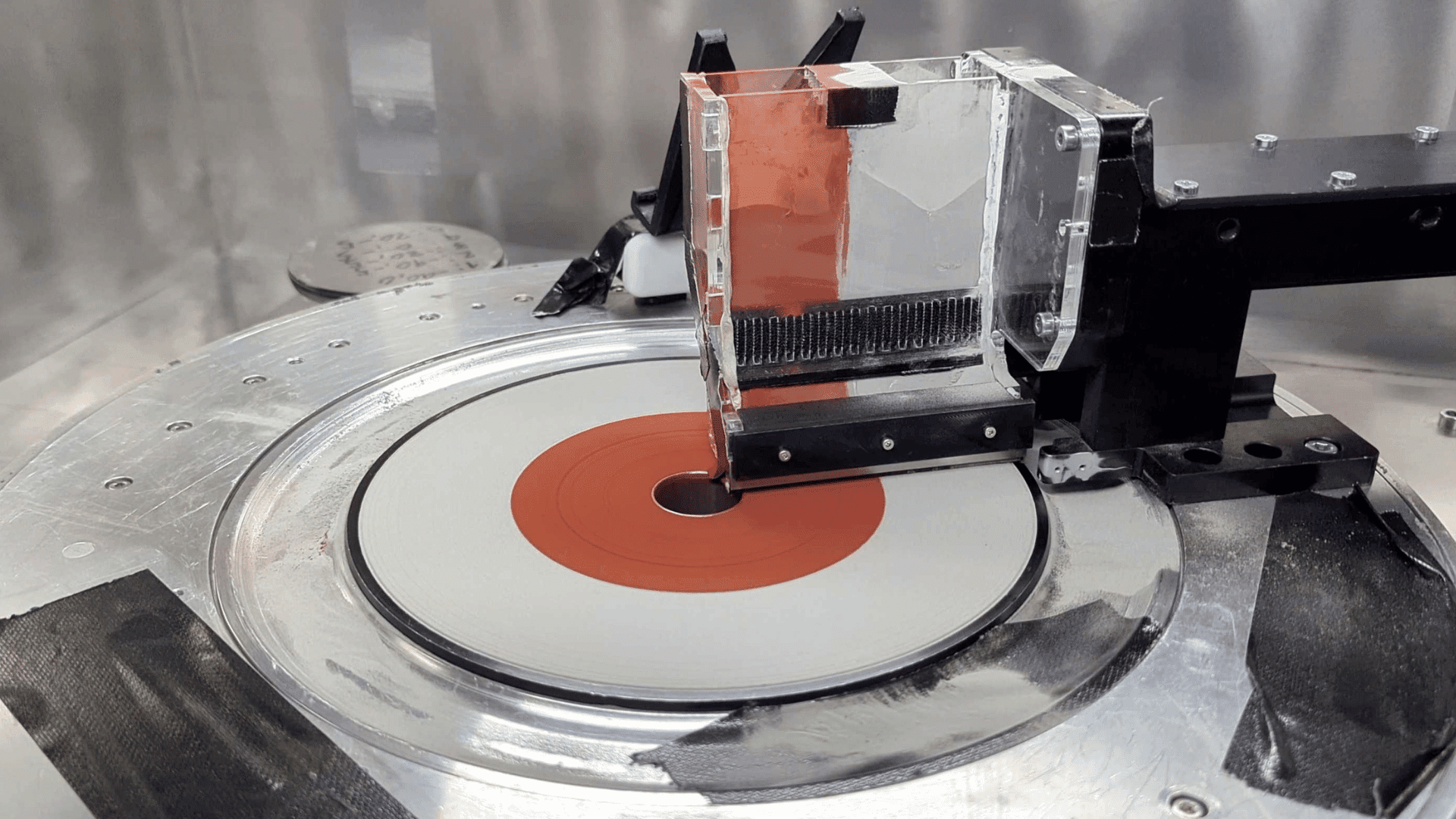

Researchers call the machine groundbreaking because it uses a laser power bed fusion system and features a rotating platform. Unlike traditional printers that apply and melt powder layer by layer, the RAPTURE machine’s platform rotates continuously. This setup allows for the simultaneous deposition of powder and fusion by a laser.

As a result, it improves productivity and reduces manufacturing time for cylindrical parts by more than two-thirds. According to the research team, this design is especially effective for large, thin-walled components like those used in rocket nozzles, turbomachines, and rotating engines.

The project started to tackle a specific challenge for ARIS, the Swiss Academic Space Initiative. The team needed to design bi-liquid-fueled rocket nozzles to handle the extreme heat and pressure during launch.

Project lead Michael Tucker said, “For small players like our student rocket team, this kind of multi-material technology has been too complex and too expensive, making it out of reach.”

In addition to its speed, the printer reduces material waste.

Traditional systems often mix powders, making leftover material useless. Researchers say the new method cuts waste by depositing material only where it is needed in the component. The machine also features a carefully controlled inert gas flow that prevents oxidation during printing, a vital detail the students found key to the product’s quality.

The students faced many challenges.

For example, they needed to design custom parts for the machine, like a special rotatable gas inlet and an automatic powder refilling system.

Despite the obstacles, they built a working prototype in just nine months. The students say the technology is ready for further development with industry partners, potentially influencing aerospace, electric motors, and other sectors.