Engineers at NC State University have unveiled compelling new research demonstrating that Composite Metal Foam (CMF) possesses significant resilience. According to the researchers, it maintains its structural integrity under repeated, heavy stress even at temperatures of up to 600 degrees Celsius (1,112°F).

This breakthrough suggests CMF could revolutionize high-performance applications where materials face both intense heat and constant mechanical loading. Applications range from advanced automobile engines to critical components in aerospace and nuclear systems. The material’s durability, combined with its high strength-to-weight ratio, makes it a promising candidate for next-generation equipment.

Excelling Under Extreme Heat and Stress

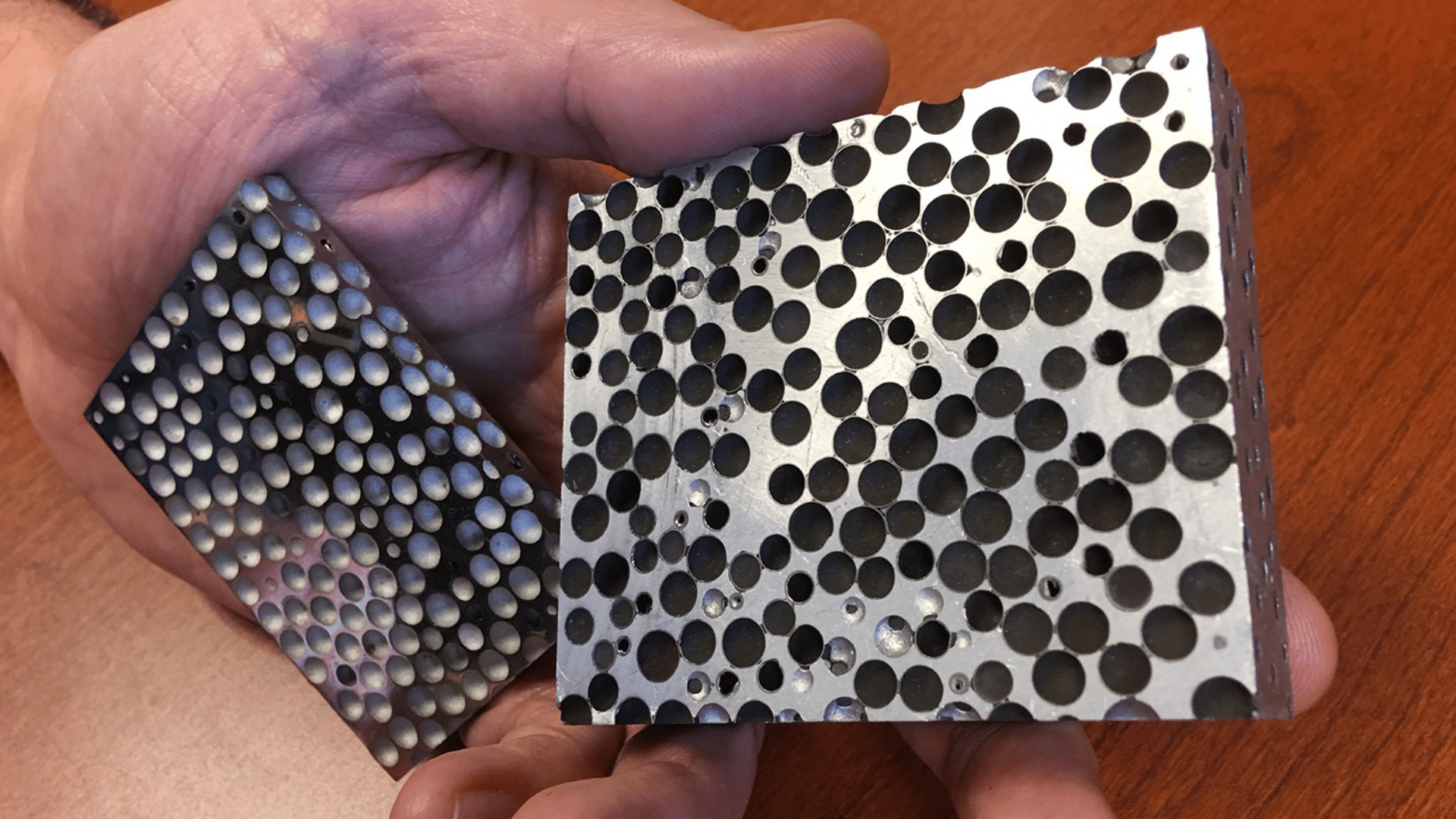

CMF is an innovative material composed of hollow metallic spheres. It’s typically made from stainless steel, nickel, or other alloys, embedded within a metallic matrix. It is known for its ability to absorb compressive forces, making it suitable for applications like vehicle and body armor.

Furthermore, NC State University engineers say that CMF provides better insulation against high heat than conventional materials, such as steel. This unique combination of strength, lightweight design, and thermal resistance is especially appealing for safety-critical roles, including the storage and transportation of nuclear materials, explosives, and other hazardous materials.

To measure its performance, the engineers conducted rigorous compression-compression fatigue testing using CMF samples made of steel spheres in a steel matrix. The material was repeatedly loaded while exposed to ambient temperatures (23°C), as well as 400°C and 600 °C.

At 400°C (752°F), the CMF survived more than 1.3 million loading cycles without failure. Even at 600°C (1112°F), it withstood over 1.2 million cycles before the tests were voluntarily halted due to time constraints.

“CMF has many attractive properties, which make it appealing for a wide range of applications,” said corresponding author Afsaneh Rabiei. “But if you want to use a material in engines, airplane parts or any application involving repeated loading and high temperatures, you need to know how the material will perform.”

The material’s stability under these extreme conditions was particularly noteworthy when compared to traditional alloys.

“Knowing that in a compression-compression fatigue setting, the fatigue life of solid stainless-steel decreases significantly as temperature increases from room temperature to 400 C and 600 C, these results were remarkable,” Rabiei added. “Our findings indicate the fatigue life of the steel-steel CMF is not diminished and that this lightweight material performs tremendously well in the extreme environment of high temperature cyclic loading.”