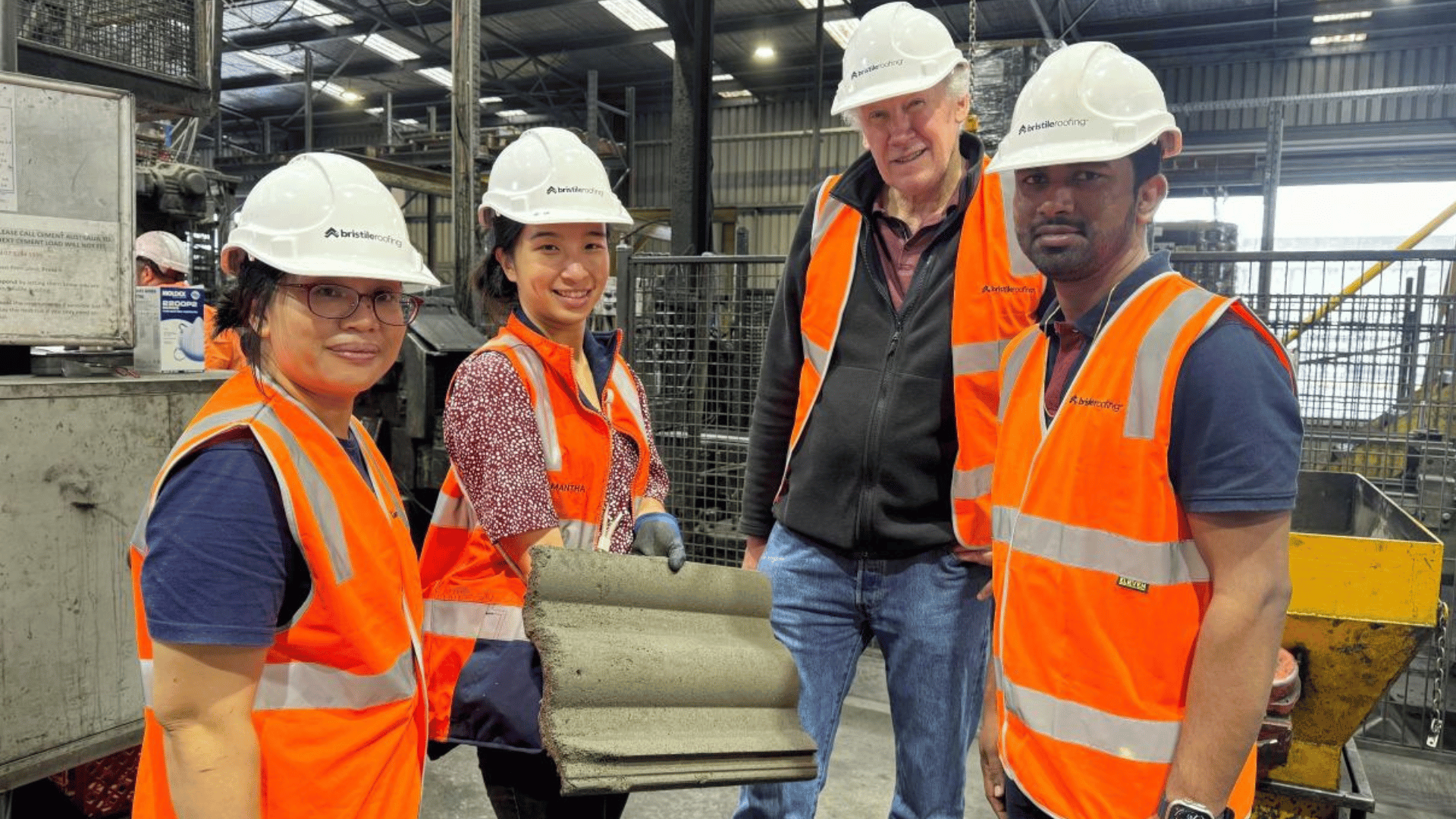

Researchers from RMIT University have successfully piloted the full-scale manufacturing of concrete roofing tiles and bricks that integrate coal ash and glass. The researchers conducted trials at Bristile Roofing’s Melbourne factory. They demonstrated a viable path for redirecting millions of tons of industrial byproducts from Australian landfills into high-performance building materials.

The initial success focused on concrete roof tiles, which met all Australian Standards for strength and durability. Additionally, the tiles offered enhanced fire resistance and a lighter profile. These new tiles replace 20% of virgin materials with waste. Specifically, 10% of cement is substituted with harvested pond ash, and 10% of river sand is replaced with unwashed recycled glass sand.

A comprehensive life cycle assessment of the new product was published in The International Journal of Life Cycle Assessment. According to researchers, it demonstrated a 13% reduction in CO₂ emissions compared to conventional concrete tiles.

A Greener Building Material

This substantial environmental and engineering benefit is a win for a country that generates approximately 12 million tons of coal ash and over 1.3 million tons of glass waste annually.

Dr. Chamila Gunasekara, RMIT project lead, said, “By replacing 10% of cement with harvested pond ash and 10% of river sand with unwashed glass waste, a total of 20% virgin material replacement, we not only reduce waste going to landfill but also produce an improved concrete product with enhanced fire resistance, a valuable feature for roofing in Australia’s climate.”

According to the researchers, harvested waste pond ash contributes to long-term performance by enhancing concrete properties, such as dimensional stability and reducing shrinkage cracking. As a result, the material is ideal for durable, non-structural applications.

Additionally, the team successfully applied the technology to concrete bricks. They created prototypes containing an even higher volume of waste, 35% in total. This satisfied Australian standards for load-bearing structural concrete.

The brick product reportedly achieves an 18% reduction in CO₂ emissions and improves insulation. According to the team of researchers, it reduced heat loss by 30% compared to conventional cement bricks.

The focus is now on scaling up to a commercial level. Dr. Gunasekara said, “We are ready to scale this for industry.” This research marks a pivotal moment in turning Australia’s waste challenges into high-value, sustainable building solutions.