Electra, a start-up backed by Bill Gates and Amazon, recently opened the doors to the world’s first “green” steel production plant. Using renewable energy, the startup in Colorado will produce clean metallic iron from high-impurity ores.

Green Steel

Electra calls its product “green” steel. The company hopes that its steelmaking process can slash the environmental cost of steel production. Ironmaking accounts for 90% of the CO2 emissions in a steelmaking process. According to Electra, that accounts for 7% of global emissions. The company uses renewable energy resources to make emissions-free iron possible.

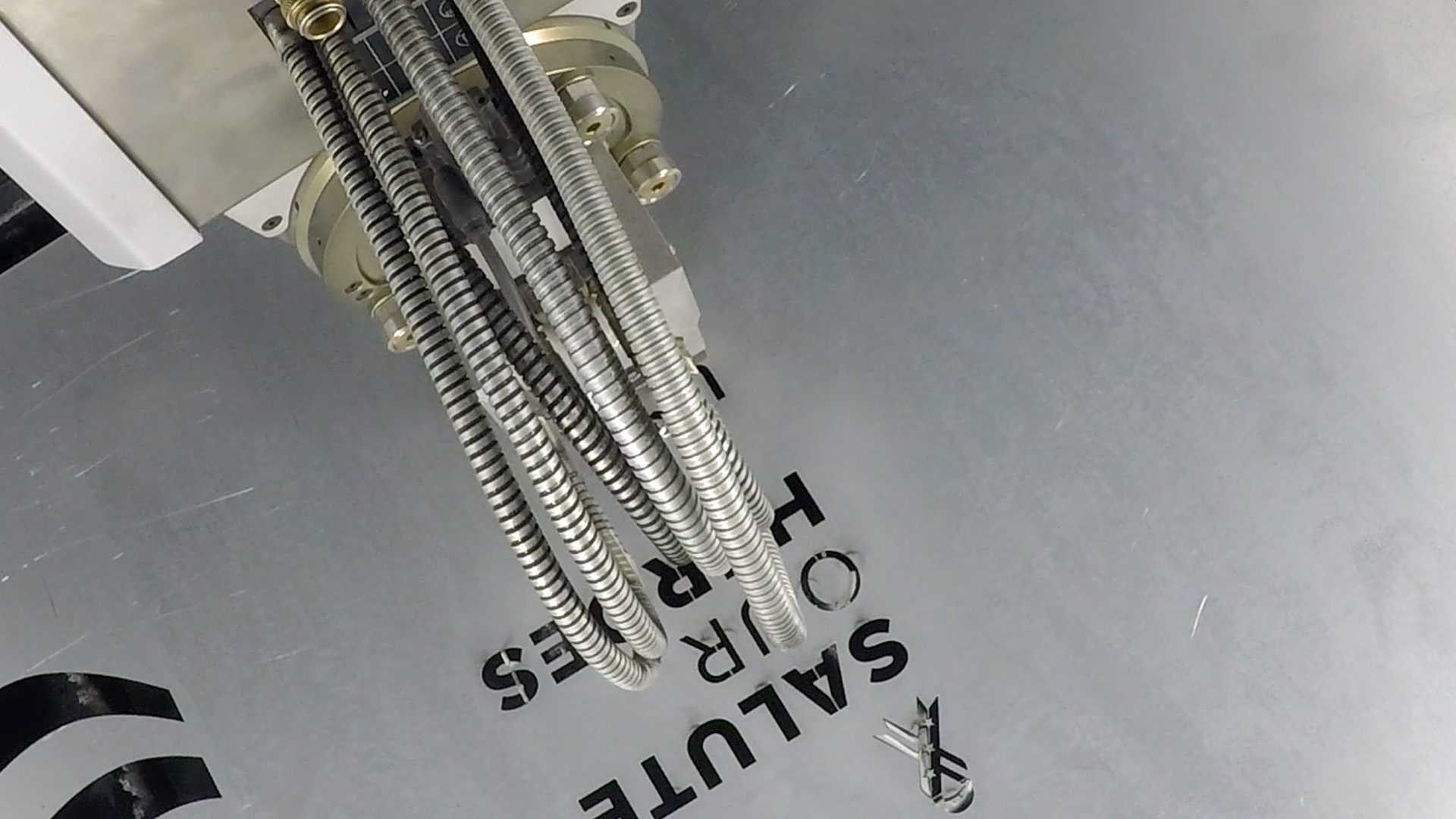

The company says it turns low-grade iron ores to high-purity iron at 140 degrees Fahrenheit. Electra says it uses “proven industrial-scale electrochemical and hydrometallurgical processes” to do this. This temperature is far lower than the coal furnaces used in traditional methods. This process takes in various ores and refines the main impurities in iron ore as co-products. These are valuable materials produced during the production process.

Electra’s clean iron is 99% pure. This purity offers the highest value for electric arc furnace (EAF) steelmakers when using recycled scrap steel. Electra CEO and co-founder Sandeep Nijhawan said, “Clean iron produced from a wide variety of ore types is the key constraint to decarbonizing the steel industry sustainably.”

Additionally, the project aims to produce clean iron plates in a 3.3-foot square size. The company says production capacity will increase gradually.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

A “Green” Opportunity

The pilot project is “green” in more ways than one. First, it is considered the world’s first green steel manufacturing plant. Second, Carmichael Roberts, who co-leads the Breakthrough Energy Ventures investment committee said it’s “a trillion-dollar market opportunity.” Breakthrough Energy Ventures is Microsoft Founder Bill Gates’s energy innovation fund.

According to a report, Electra plans to “scale up” production to commercial levels. BHP is a major supplier of seaborne iron ore to the steel industry. Additionally, they are an investor in Electra and supplied the iron ore for the pilot project. Furthermore, in 2022, Electra received $85m in funding from backers, including Breakthrough Energy Ventures. Roberts said, “Electrifying cost-effective ironmaking without carbon emissions is a paradigm shift in how steel has been made for centuries by burning fossil fuels.”

“While the road ahead is long, the arc of our progress is fast.” Electra CTO and co-founder Quoc Pham added.