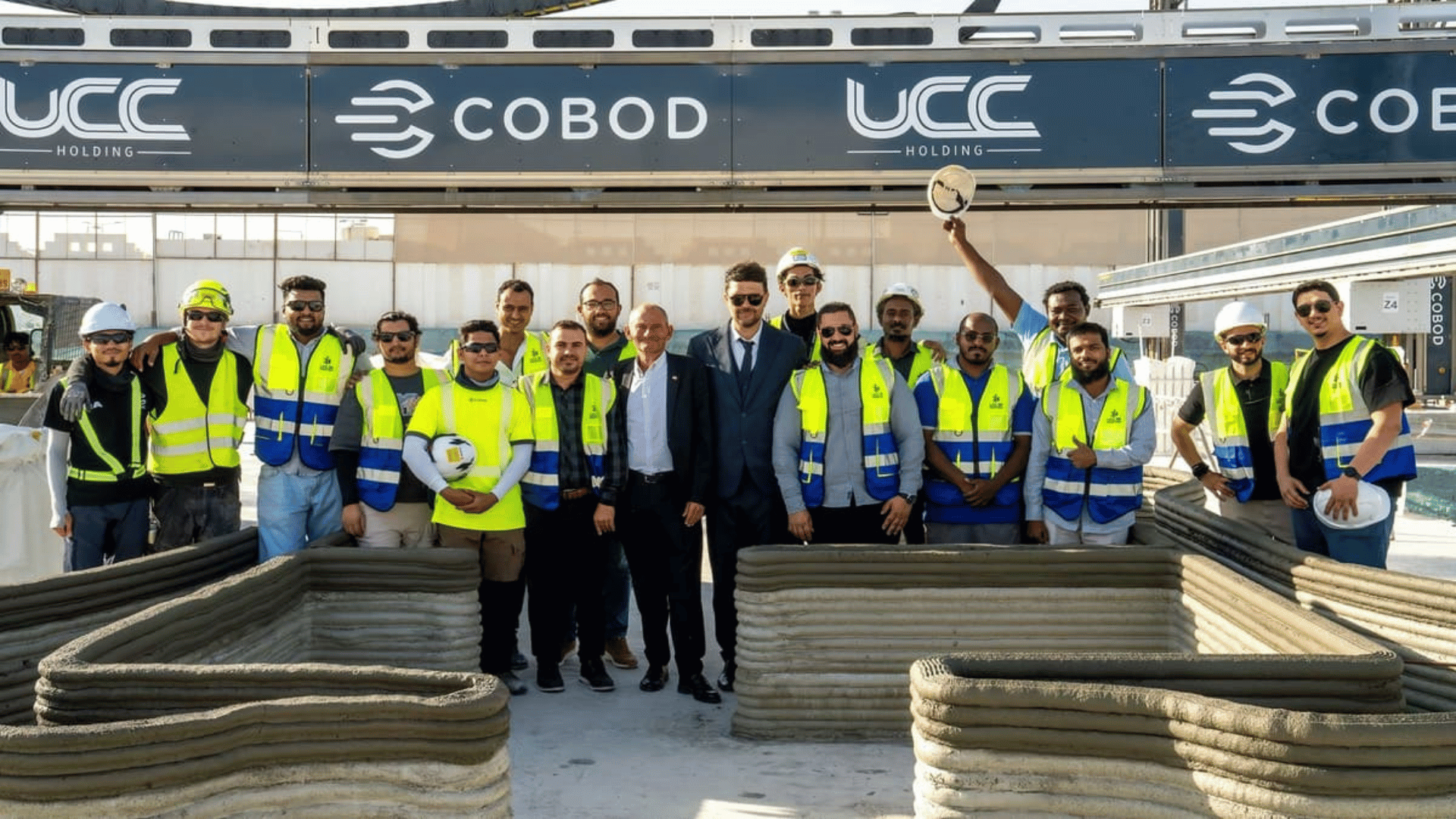

UCC Holding and Qatar’s Public Works Authority (Ashghal) have begun the printing phase of what will be the largest 3D-printed building. The project, a world first for large-scale digital construction, will use huge custom-built printers from Denmark’s COBOD.

World’s Largest 3D Printing Build

The build will construct two public schools, each spanning 20,000 square meters (approximately 215,278 square feet). This is also part of a larger plan to build a total of 14 schools across 40,000 square meters (approximately 430,556 square feet).

According to Interesting Engineering, a team of 3D construction engineers, architects, material scientists, and printer technicians has worked on the project behind the scenes for over eight months. This work involved conducting more than 100 full-scale test prints in Doha.

In May 2025, the team completed intensive training with COBOD engineers, which addressed structural layering, printer sequencing, and real-time quality control.

The new structure will be 40 times larger than the largest 3D-printed building ever made. That title was previously held by an equestrian facility in Florida, which spans just over 10,000 feet.

Qatar’s leading energy and infrastructure company has commissioned two custom BODXL printers from COBOD. Each printer is approximately the size of a Boeing 737 hangar, making them among the largest construction printers ever built.

These large machines extrude specialized layers of concrete to shape curved walls. The architecture is designed to mimic Qatar’s desert topography of curved, flowing organic forms that would be costly and challenging to create with traditional building techniques.

The teams are currently engaged in printing operations, which primarily take place at night to avoid the area’s extreme temperatures. This promotes the structural integrity of each printed layer and also reduces noise, dust, and energy consumption.

The concrete mix is tailored to perform well in Qatar’s harsh climate, and the team created a custom nozzle for precise extrusion. The project is expected to be completed by the end of 2025.