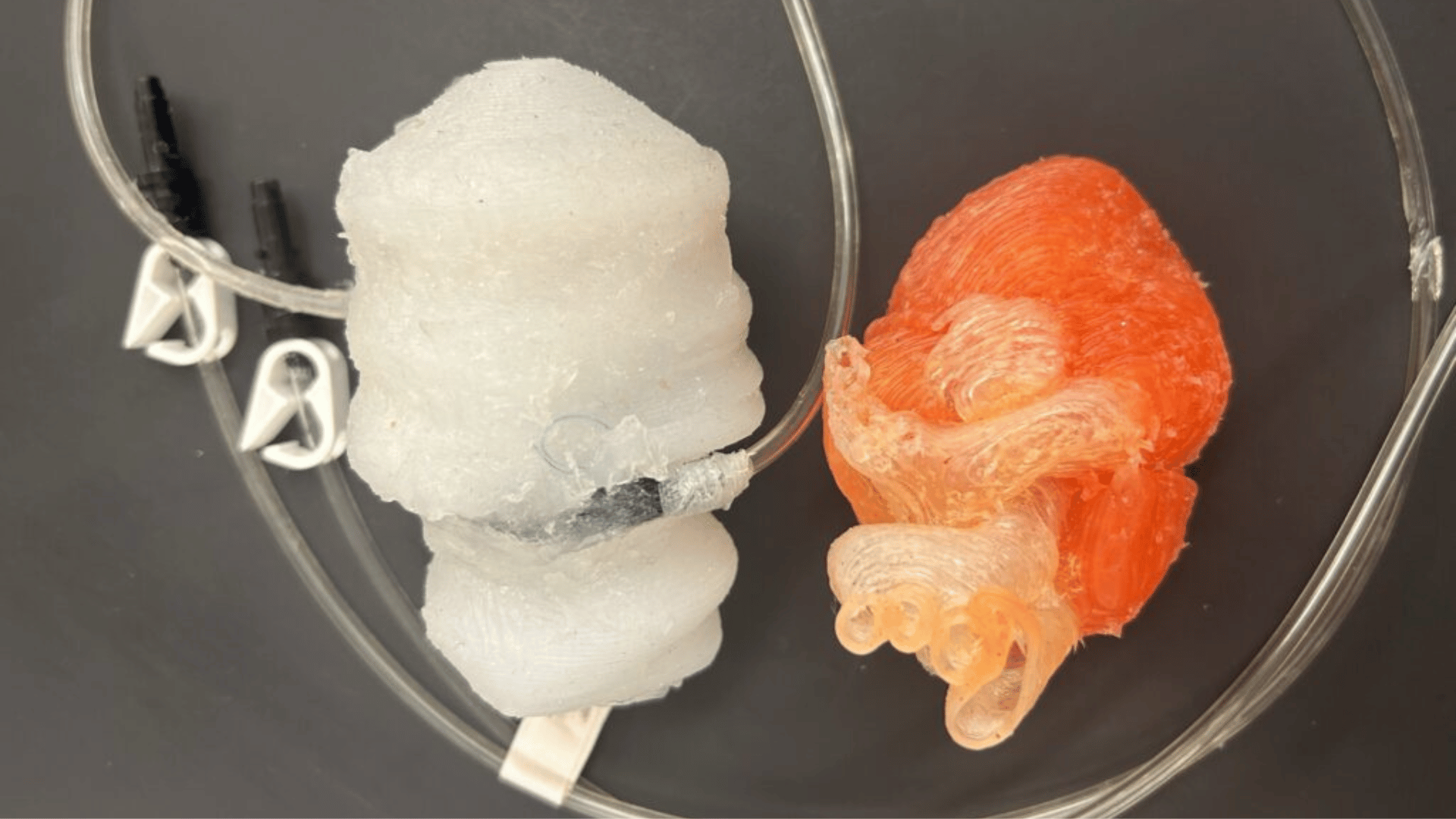

Worcester Polytechnic Institute (WPI) in Worcester, Massachusetts, has been awarded $6.3 million for an innovative approach of rapidly producing “high-quality components” from scrap metal. WPI’s initiative uses machine learning to identify scrap metals to understand how they react and bond together before being melted and 3D-printed to create strong and reliable parts.

Rubble to Rockets

The initiative is called “Rubble to Rockets.” According to scientists, it’s a new approach to 3D printing that differs from traditional methods, which require carefully controlled materials and repeated testing and adjustment. Something they say is not always possible in the real world.

“This work is crucial as it allows us to build high-quality components from unknown source materials with new confidence,” said Associate Professor Danielle Cote, Professor of Mechanical and Materials Engineering, and the lead researcher on the project. “Our goal is not just to build a single solution but to create a framework that guides future innovations.”

He added, “By improving our predictions and understanding of material performance, we can pave the way for new advancements in additive manufacturing from diverse and unpredictable sources.”

A WPI PhD student developed the AI software that predicts material behavior. The software predicts the material’s behavior at various compositions, optimizing and automating the characterization processes. Streamlining this process allows them to manufacture product data at a “rapid pace” while keeping it strong and durable.

Advertisement

Future of Manufacturing

Researchers intend to design a proof-of-concept sounding rocket to test the structural integrity of the mixed 3D-printed metals.

The researchers say the work has “broad applications” across industries including defense, energy, and transportation.

For example, it could be deployed on submarines, aircraft carriers, disaster relief zones, or remote locations. Traditionally, supply chains are difficult to maintain in these areas. They believe that identifying and transforming scrap metal into 3D-printed materials paves the way for more resilient and sustainable manufacturing solutions.

“The future of manufacturing is at the intersection of so many disciplines, including software, robotics, AI, materials science, and mechanical engineering,” said Aaron Birt, CEO of Solvus Global, a subcontractor on the grant. “This is one of those rare opportunities that demonstrates the breadth of technical expertise required to deliver a solution for manufacturing at the point of need anywhere on Earth, the moon, or beyond.”

He added, “That proposition shows the genuine ability of this team to imagine and deliver solutions of tomorrow.”