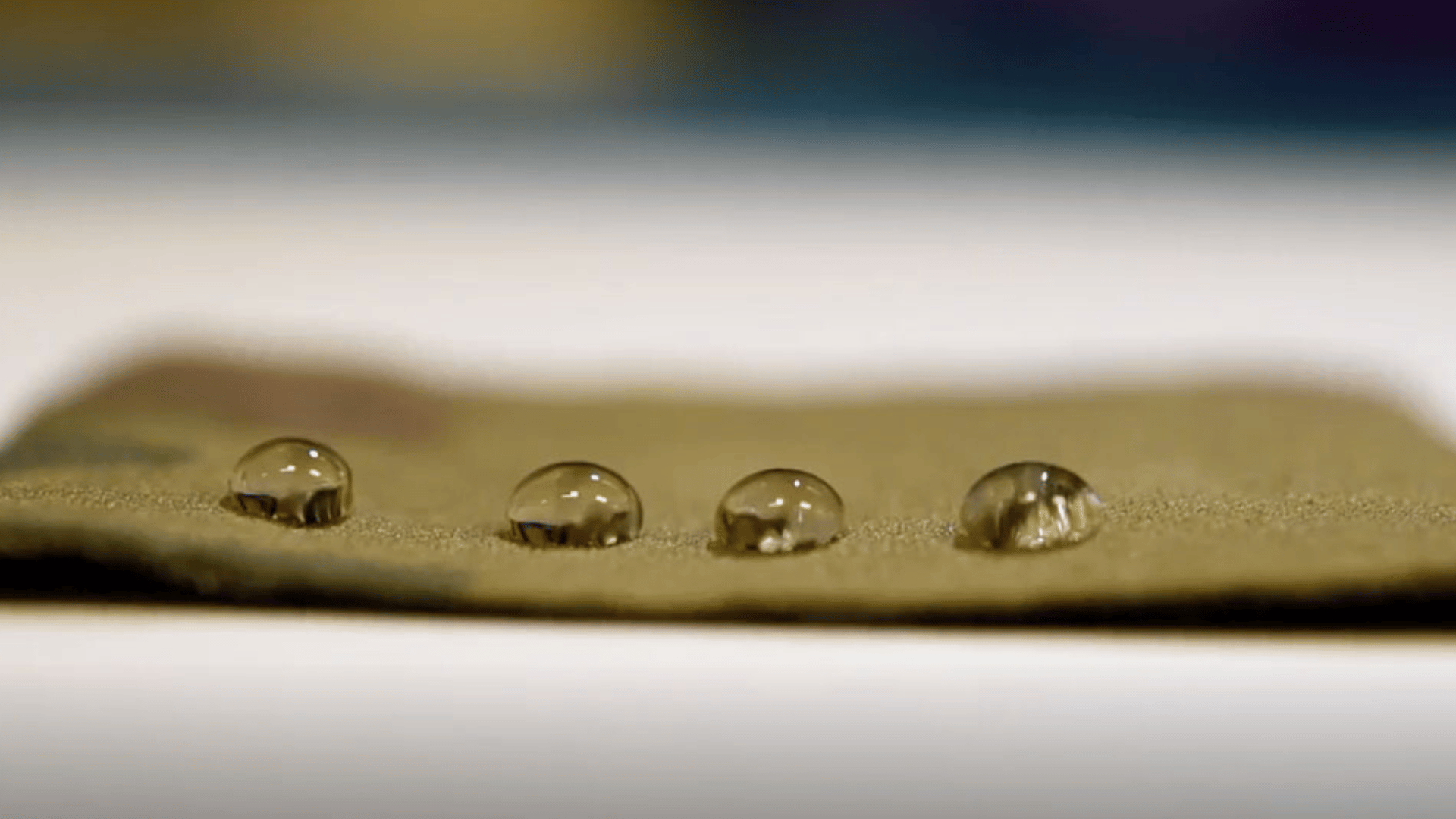

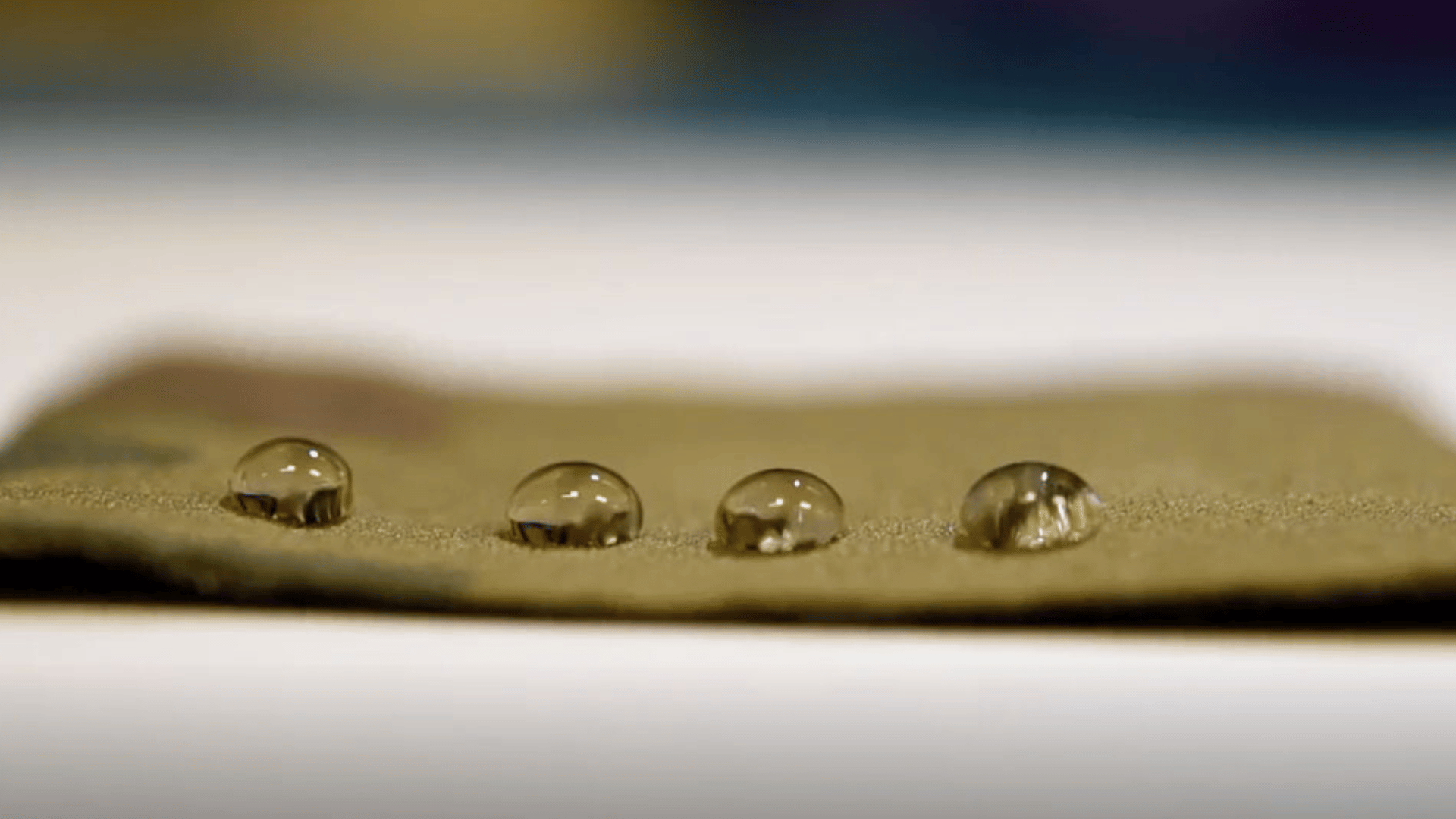

A new non-stick material could revolutionize the industry by providing a safer alternative. Researchers at the University of Toronto Engineering developed a groundbreaking non-stick material that uses less PFAS than other coatings. Its ability to repel water and grease is reportedly comparable to that of standard non-stick surfaces.

A New Non-Stick Coating Cuts Harmful Chemicals

PFAS, or per- and polyfluoroalkyl substances, are often called “forever chemicals.” According to U of T Engineering Professor Kevin Golovin, the science community has long sought alternatives to these chemicals.

“The challenge is that while it’s easy to create a substance that will repel water, it’s hard to make one that will also repel oil and grease to the same degree,” said Professor Golovin. “Scientists had hit an upper limit to the performance of these alternative materials.”

PFAS are called forever chemicals because they are resistant to breaking down. They have become a staple in popular products such as cookware, rain-resistant fabrics, and food packaging since Teflon (polytetrafluoroethylene or PTFE) was invented in the 1930s. Its non-stick properties are due to the lack of carbon-fluorine bonds. However, that is what causes their inability to break down, causing them to make their way into biological tissues. This could potentially amplify if they climb the food chain.

Researchers say various studies have linked high exposure to PFAS to certain cancers, birth defects, and other health issues.

Advertisement

According to the engineers, the new material utilizes silicone, or polydimethylsiloxane (PDMS), which is often used in biocompatible medical devices. Traditionally, PDMS could never match PFAS’s performance. The team of researchers overcame this using a novel chemistry technique that they call “nanoscale fletching.”

A Limited Number of Forever Chemicals

PhD student Samuel Au explains that their method bonds short chains of PDMS to a base material, creating “bristles on a brush.” They added the shortest possible PFAS molecule to enhance oil repellency at the end of each PDMS bristle.

“If you were able to shrink down to the nanometre scale, it would look a bit like the feathers that you see around the back end of an arrow, where it notches to the bow,” Au said. “That’s called fletching, so this is nanoscale fletching.”

The researchers noted that even though they use a PFAS molecule, it’s the shortest possible and doesn’t bioaccumulate.

“What we’ve seen in the literature, and even in the regulations, is that it’s the longest-chain PFAS that are getting banned first, with the shorter ones considered much less harmful,” Golovin added. “Our hybrid material provides the same performance as what had been achieved with long-chain PFAS, but with greatly reduced risk.”

Moving forward, the researchers want to collaborate with manufacturers in hopes of commercializing the process and pursuing further advancements.