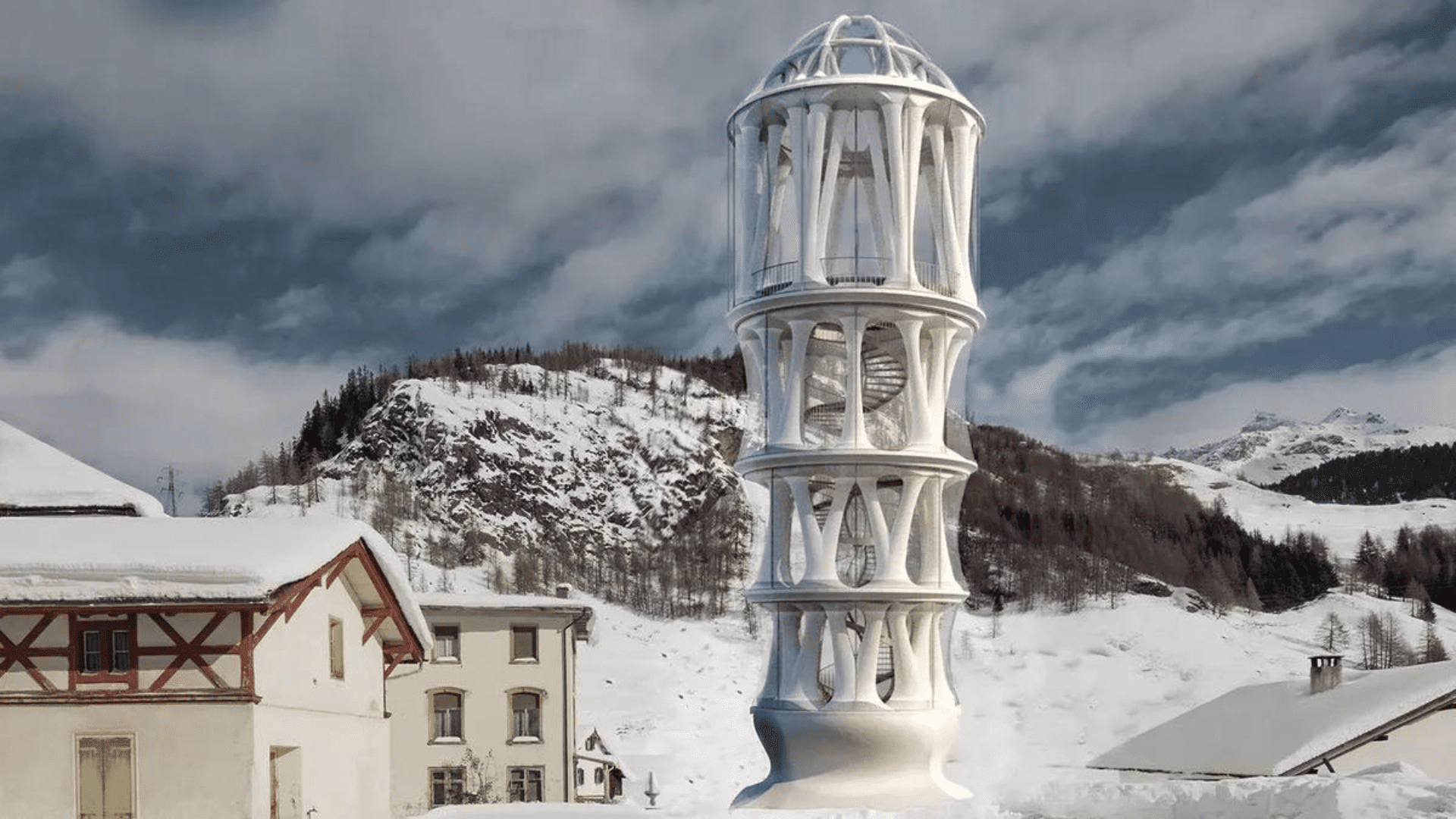

ETH in Zurich hit a major milestone in constructing the world’s tallest 3D-printed tower. Nestled in the Swiss Alps, the Tor Alva, aka The “White Tower,” is an innovation giant in the 3D-printing industry. It tops out at almost a hundred feet high, making it the tallest 3D-printed building ever constructed. Construction began on February 1 and the tower is scheduled to open this summer.

The White Tower

The White Tower will stand along the Julier mountain path in the Swiss Alps. According to a statement, the 3D-printed tower will serve as a beacon in the Mulegns Village and a versatile space for art, music, and theater performances. The tower includes 32 branching columns and can fit 45 people. Along with a beautiful panoramic view of the mountains, the tower offers atmospheric rooms that lead visitors to the concert venue at the top.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

Harsh Conditions

Winter in the Swiss Alps is harsh. It’s cold and windy with a lot of snow. Designers and architects had to keep this in mind during the design phase. To address the elements, there is a membrane that attaches to the tower during winter that shields the tower from the wind and snow during the harsh months and ensures the longevity and preservation of the building.

Design and Construction

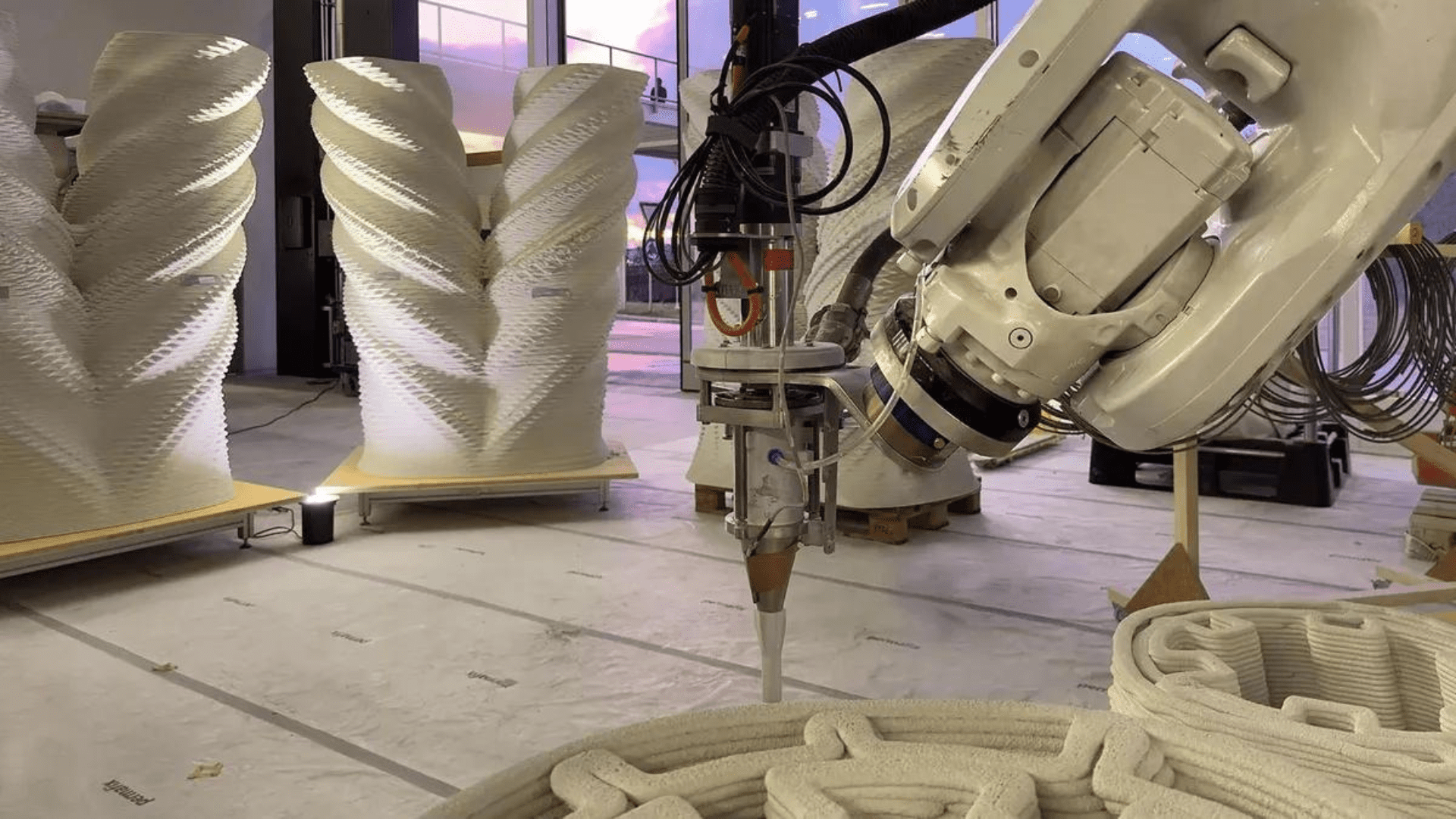

The material used for the 3D printed construction allows for “expressive shapes, surface detailing, and hollow features.” The tower has six floors. According to the firm, each floor varies in atmosphere and ambiance. As you make your way up the tower, each floor gets brighter and brighter. At dusk, the rooms illuminate the village. Despite each room and floor being different, they are all unified by the construction.

Architects lay out a digital model used to print out each layer of the tower. To help build the structure, they use a robotic arm to extrude thin layers of specially formulated concrete. For support enhancements, steel reinforcement elements may be implemented in the design for structural strength.

Once the parts are printed, they are smoothed and decorated to be assembled. Plans are in place to eventually deconstruct the tower in the future to highlight “the concept of circular economy.” When designers began the project, they also kept disassembly in mind, so it could be taken apart and rebuilt somewhere else after five years in Mulegns. It’s an innovative concept for future construction projects thanks to the capability of creating unique 3D-printed designs.