MIT researchers have utilized 3D printing to create a miniaturized mass filter, a crucial component of mass spectrometers. This new technology holds the potential to revolutionize the deployment of such devices by making them lighter, easier to produce, and more cost-effective.

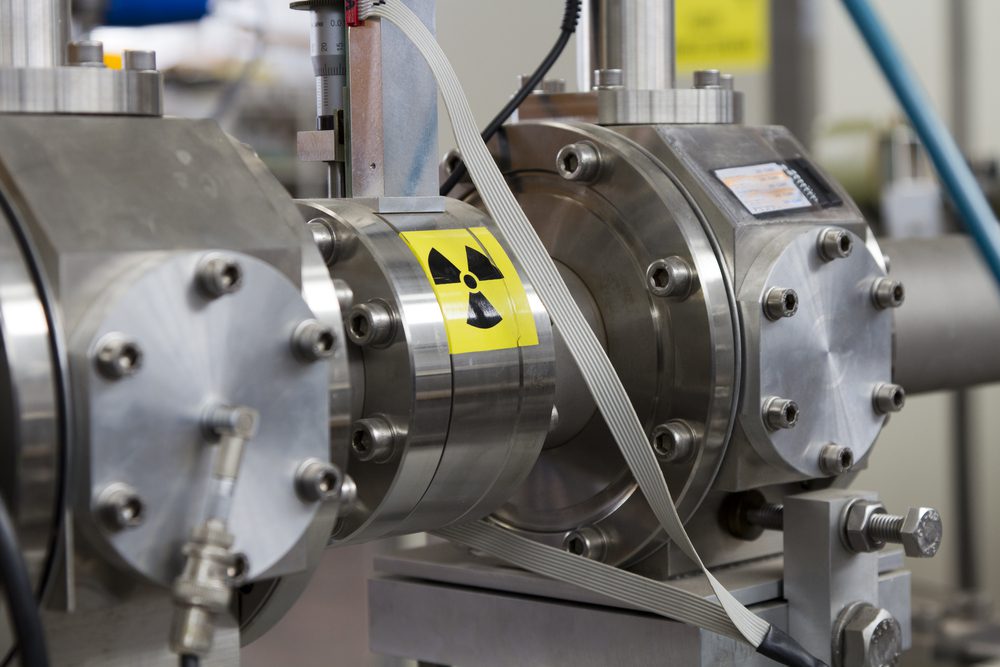

Mass spectrometers require mass filters, which are responsible for sorting charged particles based on their mass-to-charge ratio. A common type of mass filter is quadrupoles, which have traditionally been made of stainless steel which makes them bulky and expensive.

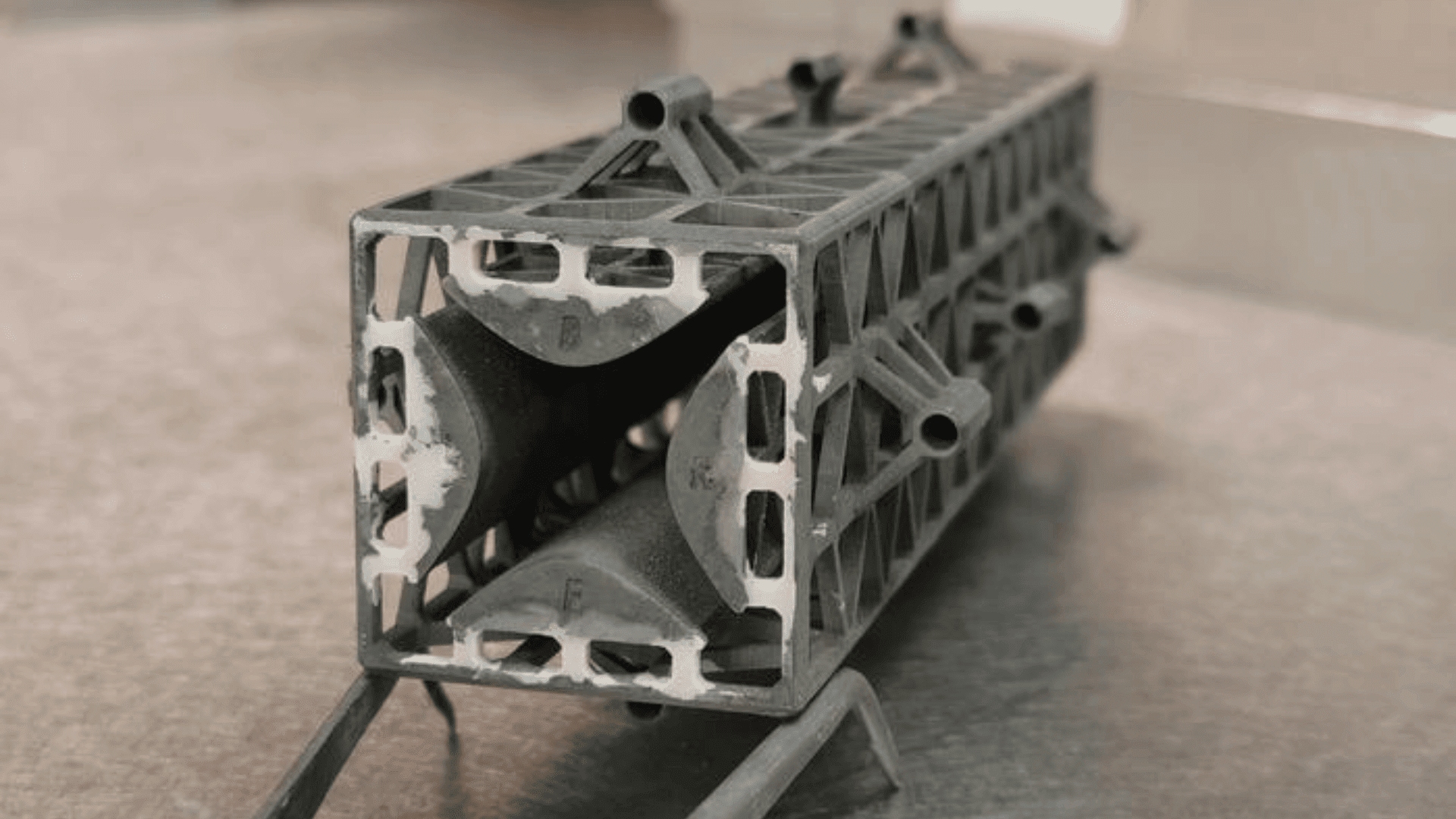

Led by principal research scientist Luis Fernando Velásquez-García, the MIT team used additive manufacturing to create a miniaturized quadrupole. Fabricated from a glass ceramic resin, the miniaturized quadrupole balances affordability and precision.

Velásquez-García highlights the significance of their approach, stating: “There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance.”

To construct the quadrupole, the team utilized vat photopolymerization which is a cutting-edge 3D printing process. The temperature-resistant glass-ceramic resin was also carefully shaped into hyperbolic rods. This design is ideal for mass filtering but it’s challenging to achieve with conventional methods.

A detailed network of triangular lattices ensures durability and proper rod positioning, even in varying conditions. The 3D-printed device is created in a single step, unlike traditional methods which may introduce defects or performance-hindering issues during assembly.

To assess the performance of the 3D-printed quadrupoles, the team implemented them into a commercial system. The results displayed higher resolutions than other miniature filters, with a quarter of the density of conventional stainless-steel filters.

“A lightweight device would be cheaper and easier to send into space, where it could monitor chemicals in Earth’s atmosphere or on those of distant planets.” Velásquez-García stated.

This achievement aligns with a 20-year goal to develop a 3D-printed, portable mass spectrometer. The MIT team aims to continue refining their 3D-printed mass spectrometer components, striving to achieve greater precision and versatility.

Researchers plan to enhance the quadrupole’s performance by extending its length, which will enable more precise measurements. Velásquez-García envisions a future where all key mass spectrometer components can be 3D printed, reducing cost and weight without compromising performance.