An electric vehicle battery always reaches the end of its life. However, with technology constantly evolving, it doesn’t necessarily mean it’s a dead end anymore. According to researchers, many “retired” batteries still hold a 70-80% residual capacity. While this capacity is no longer sufficient to power an EV, it could be suitable for a large-scale energy storage system for homes or businesses.

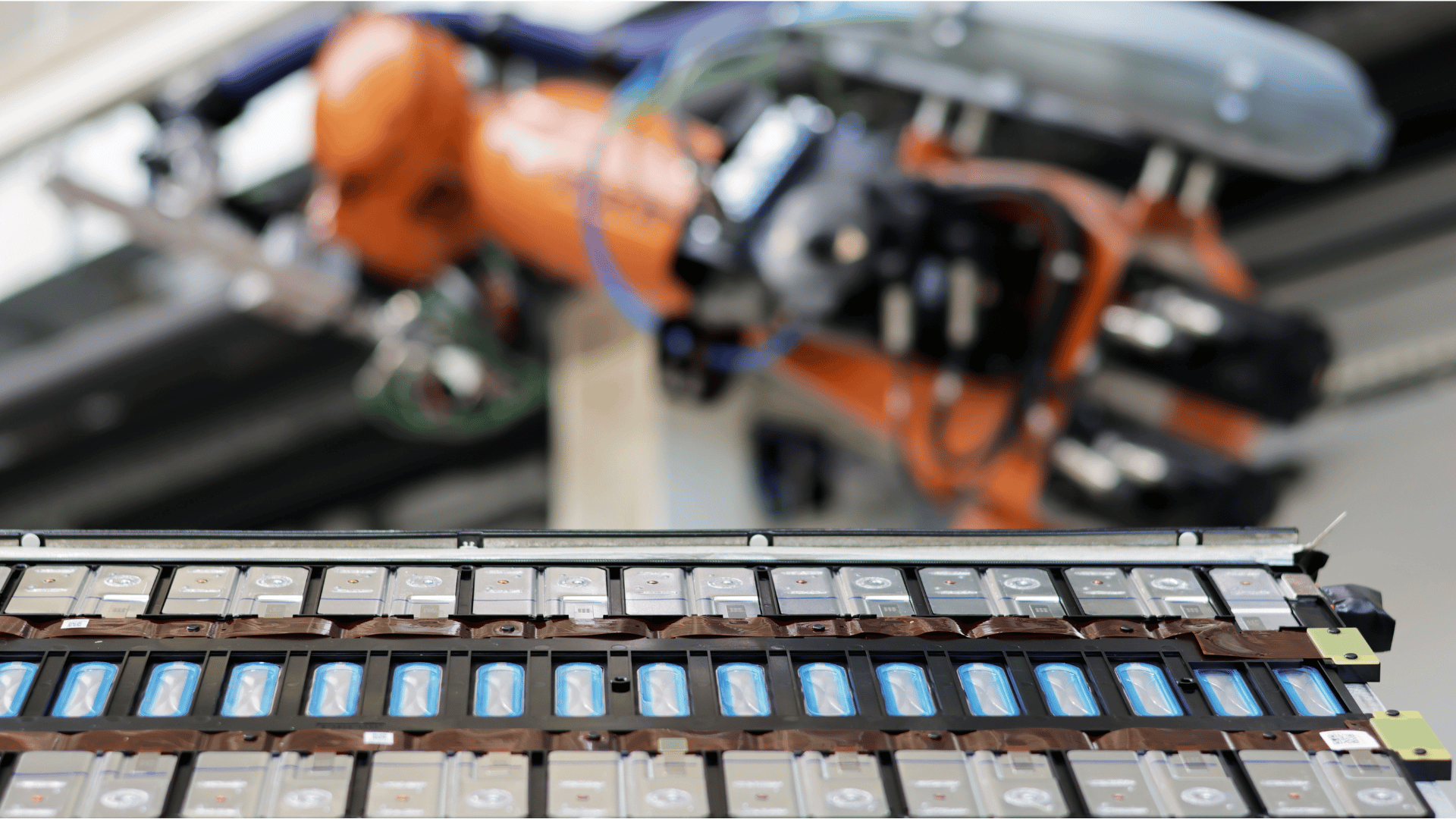

Engineers and researchers from Fraunhofer Institute for Machine Tools and Forming Technology (IWU) in Germany say shredding these batteries is a massive waste of valuable materials. Dr. Rico Schmerler and his team at Fraunhofer IWU approached this challenge to find a better way to recycle EV batteries.

A Second Life For EV Batteries

A new plant is at the core of their effort. It’s located in Chemnitz, Germany, where Fraunhofer IWU is located. Researchers believe that a solution is needed and urgent because the number of used batteries in the EU is expected to increase “more than tenfold.” As researchers explained, moving beyond conventional recycling and shredding processes is critical. According to Dr. Schmerler and his team, their new plant will achieve damage-free disassembly of batteries down to the cell level. As a result, it will be possible to either swap out defective cells or remanufacture entire units for new applications.

In addition, the new facility is built on automation and is powered by artificial intelligence.

Researchers say the plant will use AI-supported dismantling to handle various high-voltage storage systems safely and economically. An integrated system will analyze the health of each module and cell to ensure that only the components with sufficient functionality are reused. In addition to the plant’s physical dismantling role, the new facility will serve as a data platform to standardize the recycling and recovery process. Data collected will help researchers develop new qualification profiles for skilled workers.

Ultimately, the researchers want to preserve precious resources with this new plant. As a result, it would reduce the need for new, energy-intensive production and make recovering valuable raw materials from cells easier. The innovative process could enhance the life cycle of EV batteries, which companies are desperately trying to do.