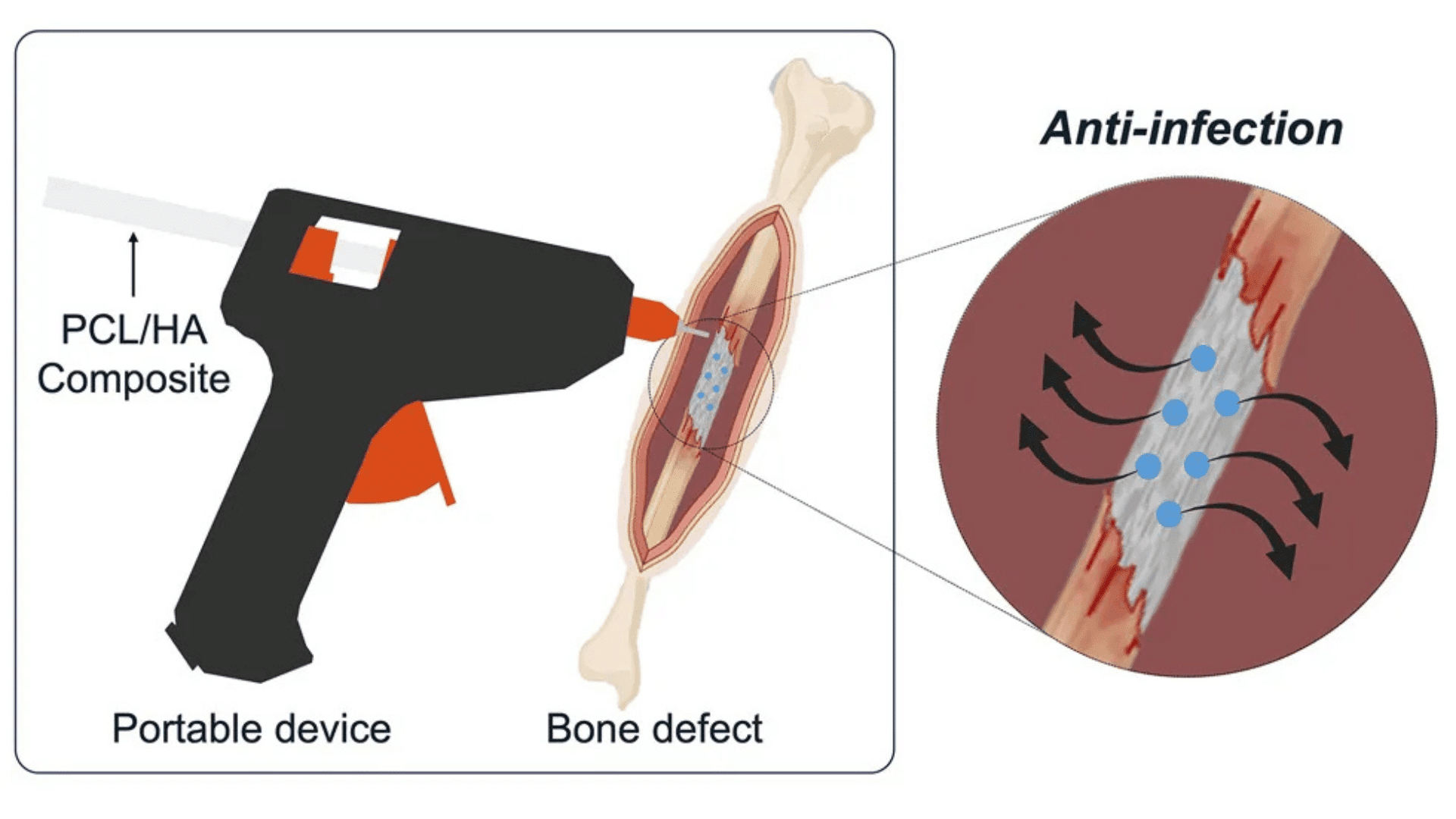

Scientists have modified a standard glue gun to 3D print a bone-like material directly onto fractures. After testing the technology on rabbits with leg fractures, researchers believe it could be useful for fixing irregularly shaped fractures during surgery.

Fixing Fractures With a 3D Printing ‘Glue Gun’

Large fractures and other bone defects usually require bone grafting and the use of a metal fastener, such as a plate or pin. Because the shape of these implants isn’t customized to the patient’s fracture, it can cause poor alignment.

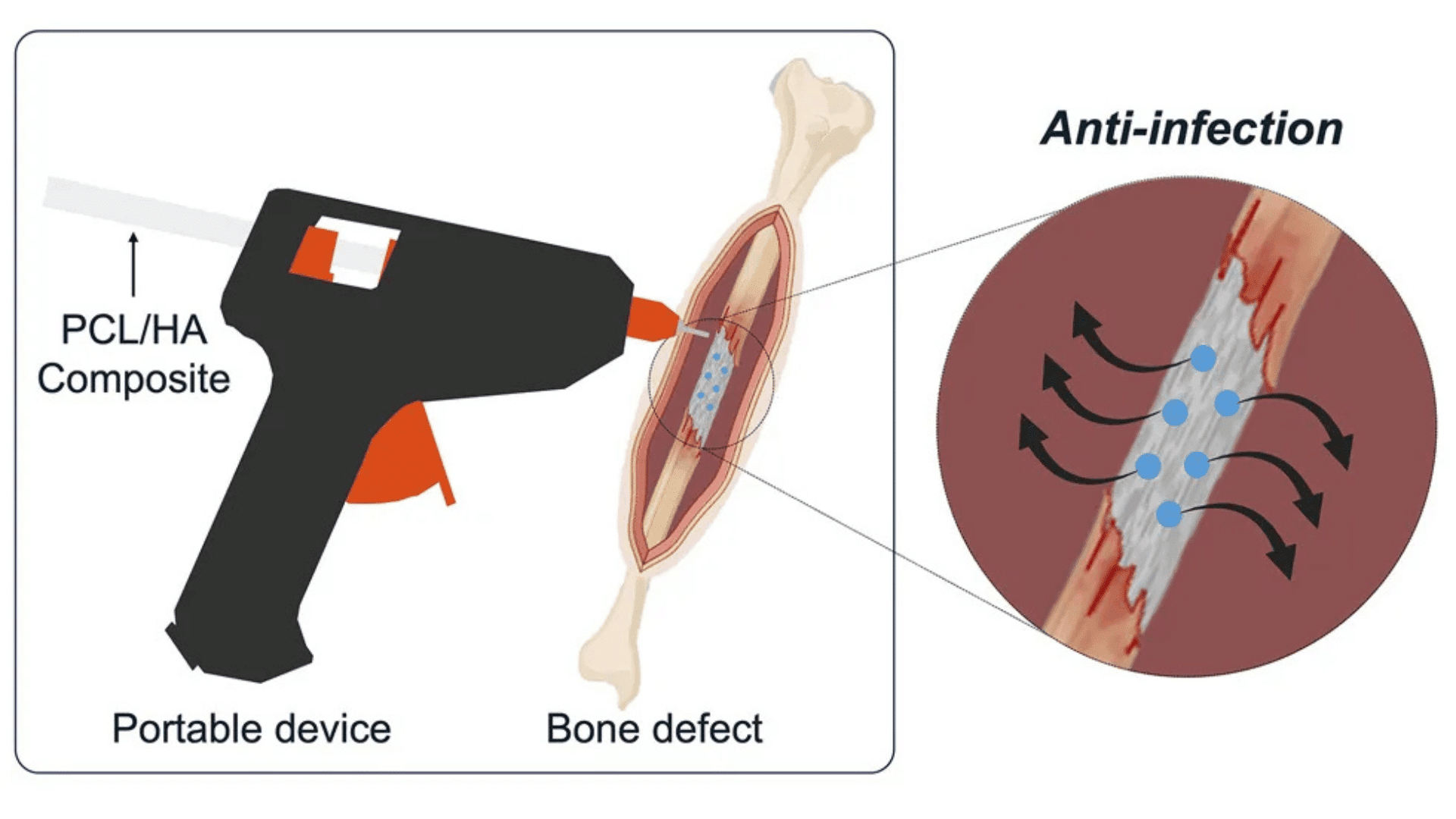

Though 3D-printing custom bespoke bone grafts for patients has been done before, they require significant time and effort to make. A recent study presented a new 3D printing method that places a bone substitute directly onto the fracture using a modified glue gun.

“To my knowledge, there are virtually no previous examples of applying the technology directly as a bone substitute,” study co-author Jung Seung Lee, a biomedical engineer at Sungkyunkwan University in South Korea, told Live Science. “This makes the approach quite unique and sets it apart from conventional methods.”

Advertisement

Whereas 3D printing typically uses a flexible, plastic thread that’s heated and formed into shapes, researchers created a filament composed of two materials: polycaprolactone (PCL) and hydroxyapatite (HA). Polycaprolactone has been previously used to create biodegradable bone scaffolds, and hydroxyapatite is a mineral form of calcium crucial for bone structure. Two antibiotics, which diffuse slowly over several weeks, were also incorporated to prevent infection.

Using the modified glue gun, researchers created small shapes that cooled to body temperature within 40 seconds.

“Because the device is compact and manually operated, the surgeon can adjust the printing direction, angle, and depth during the procedure in real time,” said Lee in a press release. “Also, we demonstrated that this process could be completed in a matter of minutes. This highlights a significant advantage in terms of reducing operative time and improving procedural efficiency under real surgical conditions.”

When testing the technology on rabbits, they filled the rabbits’ bone defects with either their special bone-like filament or with traditional bone cement. After following the rabbits’ progress over 12 weeks, they noted that the rabbits with the new fracture treatment had better bone tissue formation and denser bone growth compared to the traditional treatment.

“We have confirmed the therapeutic potential of this technology using a rabbit model,” Lee told Live Science. Though further studies in larger animals are needed before the technology can be used on humans, Lee said, “We believe this approach has the potential to be used more widely in future trauma surgery.”