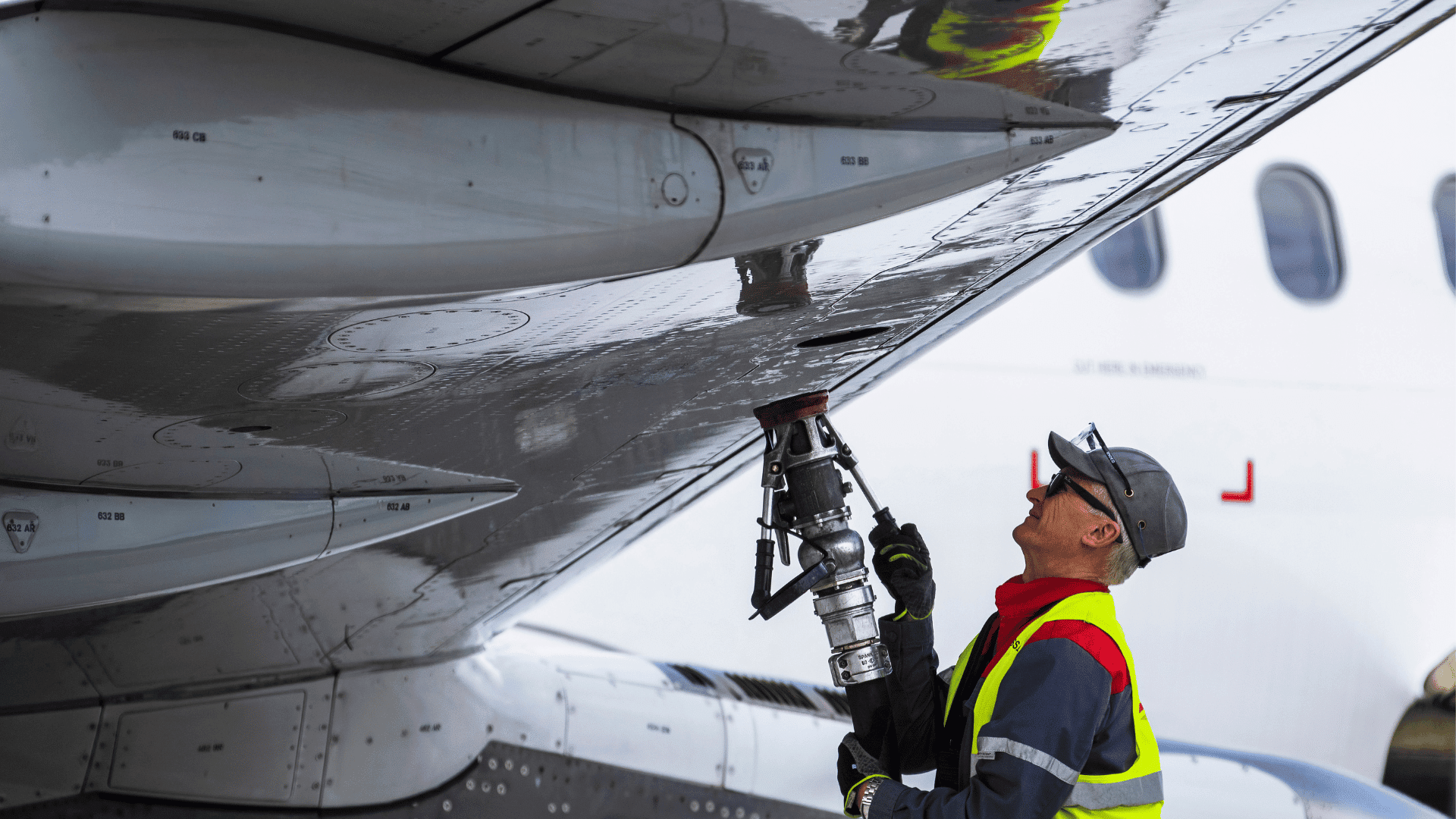

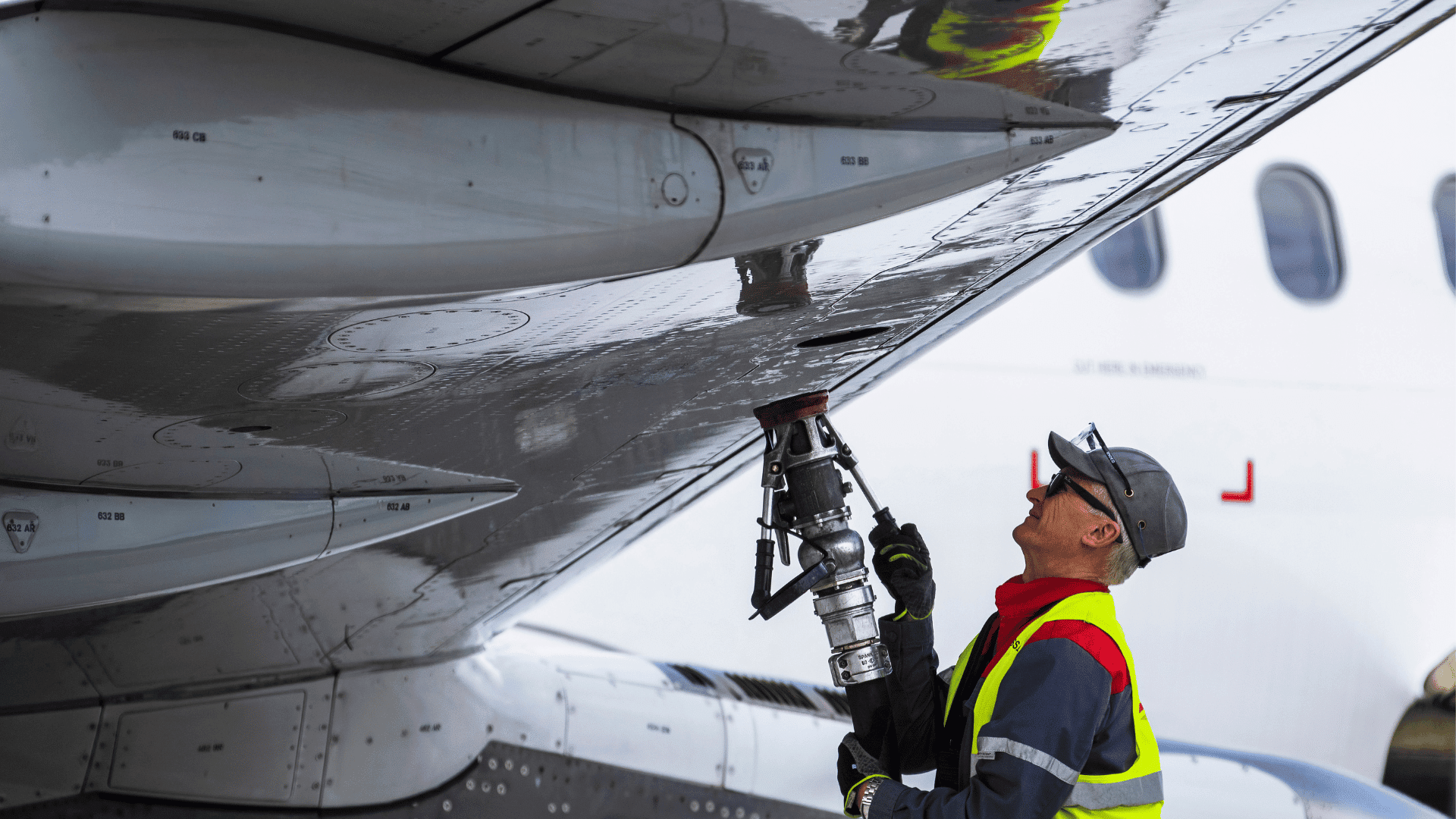

Corn-based ethanol production releases CO2, which is often viewed as a waste byproduct. However, researchers believe it could be transformed into a key ingredient for Sustainable Aviation Fuel (SAF). A new report from researchers at the University of Michigan explores pathways to recycle the existing carbon source into a climate solution for the aviation industry.

CO2 from ethanol fermentation is uniquely valuable. The fermentation process yields pure streams containing 85% CO2 by volume or higher, unlike gas streams from industrial processes. This makes it easier and less energy-intensive to capture. Because the CO2 was originally separated from the air by corn plants, capturing and reusing it for fuel creates a carbon-recycling loop that does not add new CO2 to the atmosphere.

Defossilizing Aviation Fuel

Aviation produces over a gigaton of fossil CO2 emissions annually. Researchers believe it is essential to find scalable, non-carbon stocks. The U.S. ethanol industry’s 2023 output of 15.6 billion gallons released 48 megatons of CO2. This presents a huge, ready-to-scale resource.

Advertisement

U-M research scientist Stephen McCord said, “It is exciting to explore whether this ‘waste’ stream can actually become a significant asset, turning inefficiency into advantage and accelerating the real-world application of emerging technologies.”

U-M researchers compared an existing corn-based SAF production method called Alcohol-to-Jet (AtJ) with two new CO2-based routes. According to researchers, the AtJ process is effective but achieves a carbon reduction of only 4.5% to 20% compared to conventional jet fuel.

The two CO2-based pathways, however, start by converting captured CO2 into syngas (carbon monoxide and hydrogen). One path, Gas Fermentation, creates ethanol using syngas before using the AtJ process. The second path, Fischer-Tropsch Synthesis, feeds syngas directly into a reactor to synthesize long-chain liquid jet fuel hydrocarbons.

A lifecycle assessment of the two methods projected substantial environmental benefits for both CO2 routes. However, the Gas Fermentation route was deemed the path with the “smoothest transition.”

“These conversion routes provide a viable way to ‘defossilize’ aviation fuel and make meaningful progress towards reducing aviation’s carbon footprint,” said McCord. “Offering a realistic, near-term solution where alternatives are limited.”