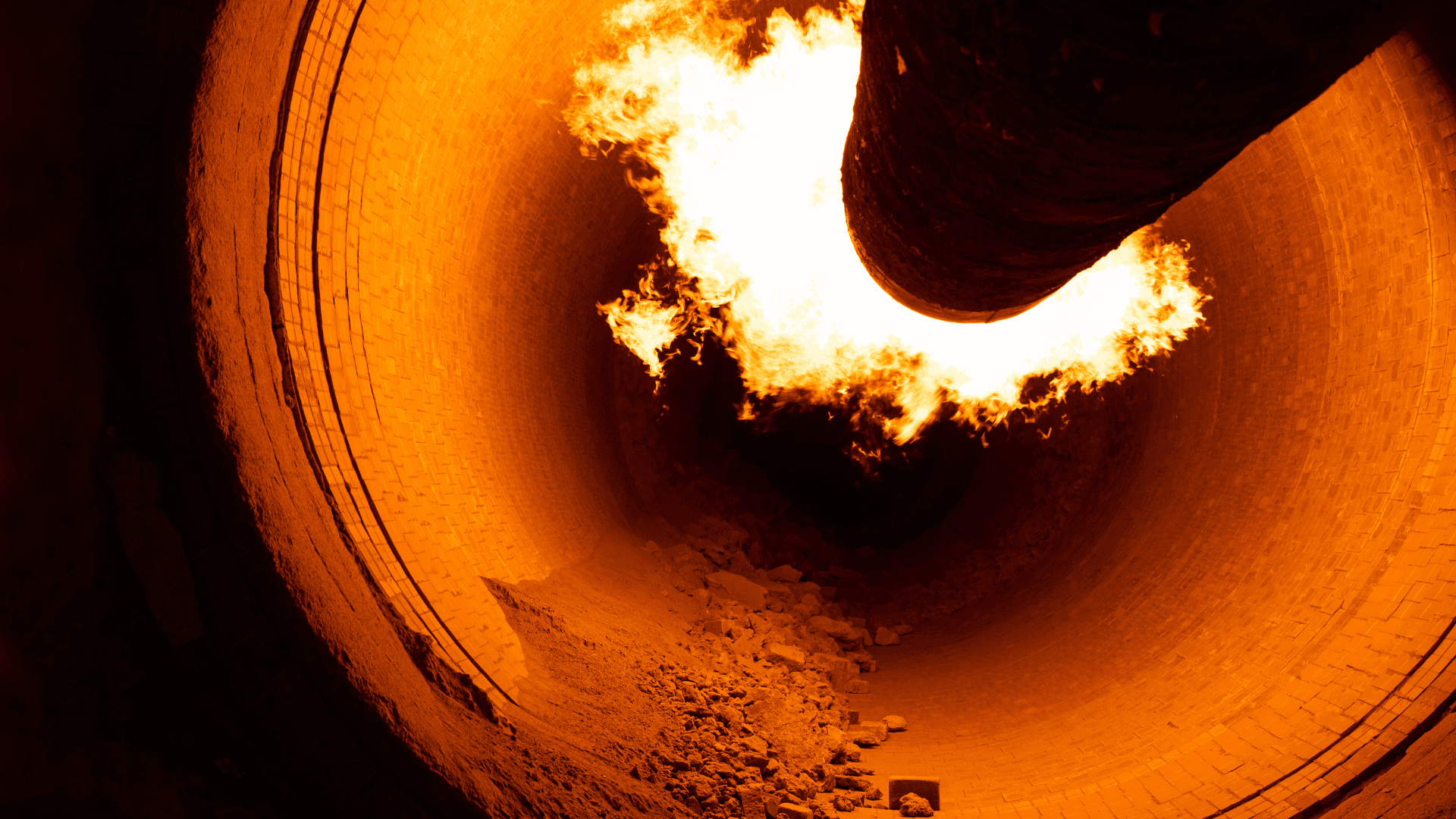

Cement is critical for global infrastructure, such as roads, buildings, and bridges. However, cement production faces a significant challenge because of its high carbon emissions. The emissions primarily come from the chemical release of CO2 from limestone during high-temperature burns in rotary kilns.

A team of researchers at the Paul Scherrer Institute for Nuclear Engineering and Sciences wants to address the issue head-on. They propose replacing some of the cement’s main components with alternative materials to reduce emissions while maintaining performance. The team trained an AI model to create new cement formulations and predict their CO2 emissions in milliseconds.

Potential of the AI Model

According to the researchers, the AI functions as a “digital cookbook.” For example, it generates “practical, climate-friendly” recipe suggestions. It also identifies promising lab testing candidates, eliminating the need to experiment with thousands of variations, which could speed up the development cycle.

The researchers say the model leverages “genetic algorithms,” an AI technology inspired by natural selection. Rather than random compositions, the AI model specifically searches for recipes that meet the team’s desired criteria, such as maximizing performance and minimizing emissions.

Furthermore, the AI tool can expand to include additional factors, such as raw material availability, production logistics, or environmental conditions of the location where the cement will be used.

Most importantly, the AI model is meant to rapidly create potential, eco-friendly cement recipes.

“To put it bluntly, humanity today consumes more cement than food – around one and a half kilograms per person per day,” said John Provis, head of the Cement Systems Research Group. “If we could improve the emissions profile by just a few percent, this would correspond to a carbon dioxide reduction equivalent to thousands or even tens of thousands of cars.”

The study is a proof-of-concept, highlighting the potential of AOI and research to create a more sustainable, high-quality cement. Lab testing remains a major part of the team’s study; however, AI offers an unprecedented accelerator for “doing geology in fast motion,” Provis explained. They hope to accelerate the path to net-zero emissions in cement production.