Since cement contributes to approximately 8 percent of global CO2 emissions, creating eco-friendly cement would be immensely beneficial for the environment. A new study shows that a mineral called olivine could be used to make carbon-negative cement.

Most of these emissions occur when heating limestone to produce clinker (a binder in cement) or burning fossil fuels to generate heat. Olivine is an abundant mineral that is one of the main components of Earth’s mantle and resides in every continent.

“It’s one of the few minerals that is available at the gigatonne scale,” says Sam Draper at Seratech, a UK-based company that has patented a process to turn olivine into cement.

Several start-ups like Seratch are attempting to develop low-carbon methods to produce cement like supplementing with steel by-products or recycling the CO2 released in cement production. Draper and his colleagues had the idea of utilizing olivine as a replacement for the usual clinker.

Not only is olivine abundant and more environmentally friendly, it also contains silica which makes cement stronger and more durable. Magnesium sulfate can also be extracted from it, which reacts with CO2 to form minerals that isolate the gas.

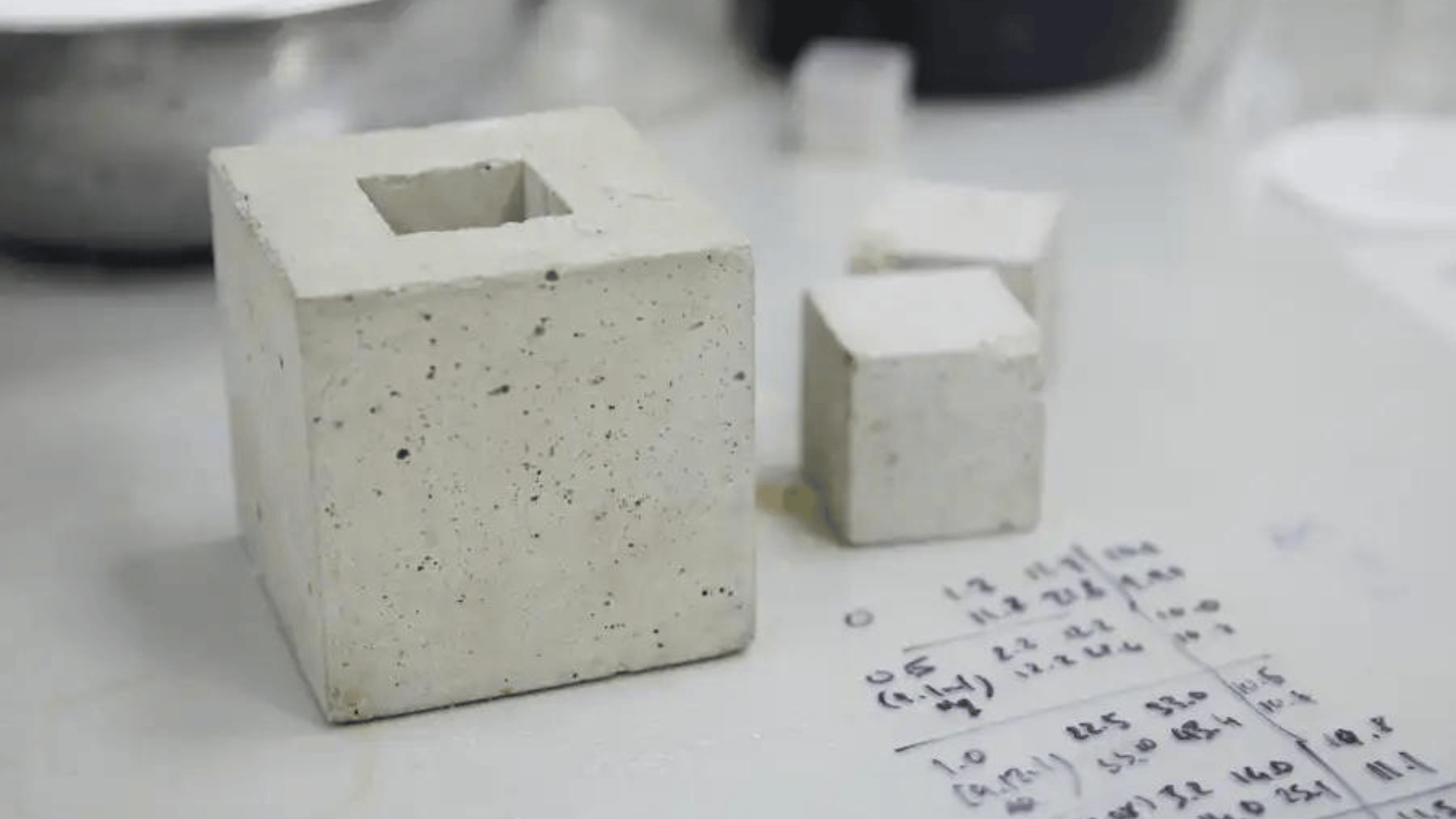

The team dissolved powdered olivine in sulphuric acid to extract the compounds. After the magnesium sulfate and silica were separated, they bubbled CO2 through the magnesium slurry to form a mineral called nesquehonite.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

When scaling up the process, Draper stated that a cement plant would use CO2 captured from an emissions source from the air for the process – rendering it carbon-negative. Additionally, any leftover nesquehonite could be recycled into new construction materials such as bricks, boards, or blocks.

Researchers estimated that replacing 35 percent of the regular cement in a concrete mix with silica for this process would result in carbon-neutral cement and substituting an additional 40 percent would produce carbon-negative cement.

Though they haven’t yet made enough for robust testing, Draper stated that current building standards allow this type of material to replace up to 55 percent of cement.