Building a massive fusion reactor like ITER is a bit like trying to assemble a high-tech puzzle with heavy pieces and tight spaces. To get the job done, engineers are rethinking how they put everything together, moving away from doing one thing at a time and toward a method where multiple teams and robots work at once.

The Rolling Wave Strategy

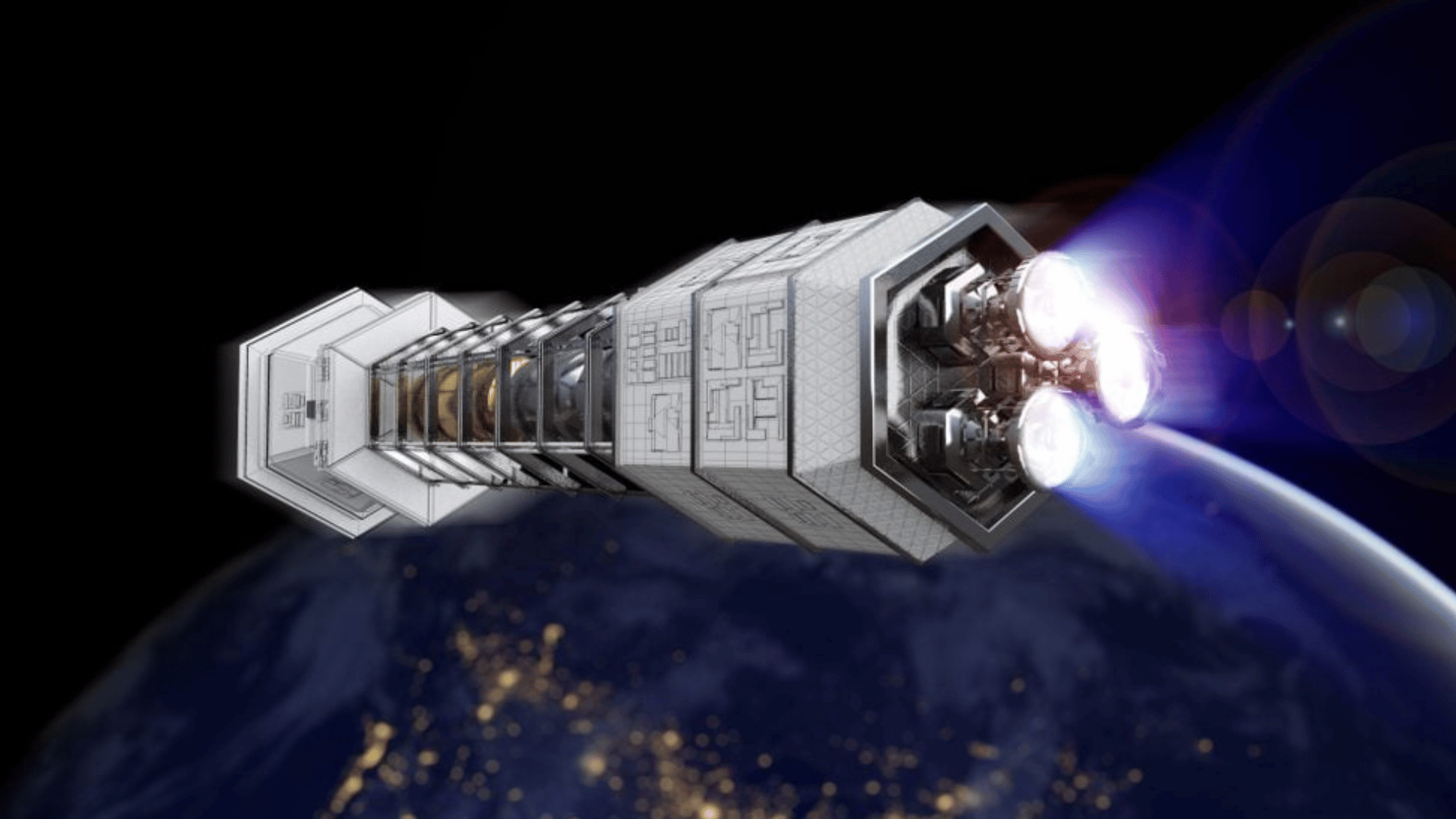

This new approach is called the “Rolling Waves” concept. Instead of waiting for one task to finish before starting the next, different teams will move through the reactor’s vacuum vessel in layers.

“Specialized teams and assembly tools will move from one part of the vacuum vessel to the next to install a specific ‘layer’ of components. As they advance, another team moves in to install the next layer,” Raphaël Hery, an expert in robotics for harsh environments, explained. He said this strategy significantly reduces installation time and safety risks.

Meet the Godzilla Industrial Robot

To make this work, the team is using a massive industrial robot nicknamed “Godzilla.” Standing 4 meters tall with a 5-meter reach, it’s the most powerful industrial robot on the market, capable of lifting 2.3 tons. However, Godzilla doesn’t go inside the reactor. Instead, it’s acting as a test dummy or a “platform” to develop the tools that the actual assembly robots will use.

One of the most important things being tested is a “tool changer.” Since the assembly requires over 30 different types of tools for welding, cutting, and bolting, the robots need to be able to swap them out quickly.

Engineers are also giving these robots sight and touch. New vision systems will help them align parts perfectly, while sensors will allow them to “feel” how much pressure they are applying.

“In the restricted and densely packed environment the assembly robots will be operating in, the sense of sight and touch will be essential to ensuring precise and secure movement that does not damage the vacuum vessel or nearby components,” said Raphaël.

Once these tools pass Godzilla’s tests, they will be moved to even larger machines, including a 36-ton transporter currently being designed.

“Developing robust systems and processes to prepare for in-vessel assembly is a truly colossal task,” Raphaël said. “And although actual operations are still years away, the teams are under a very tight schedule.”

When the work finally begins, these robots will run 24 hours a day, six days a week, for about two years to get the job done.