Australia is finding a way to solve a problem that has bothered space and defense experts for decades: how to keep things running when you can’t change the batteries.

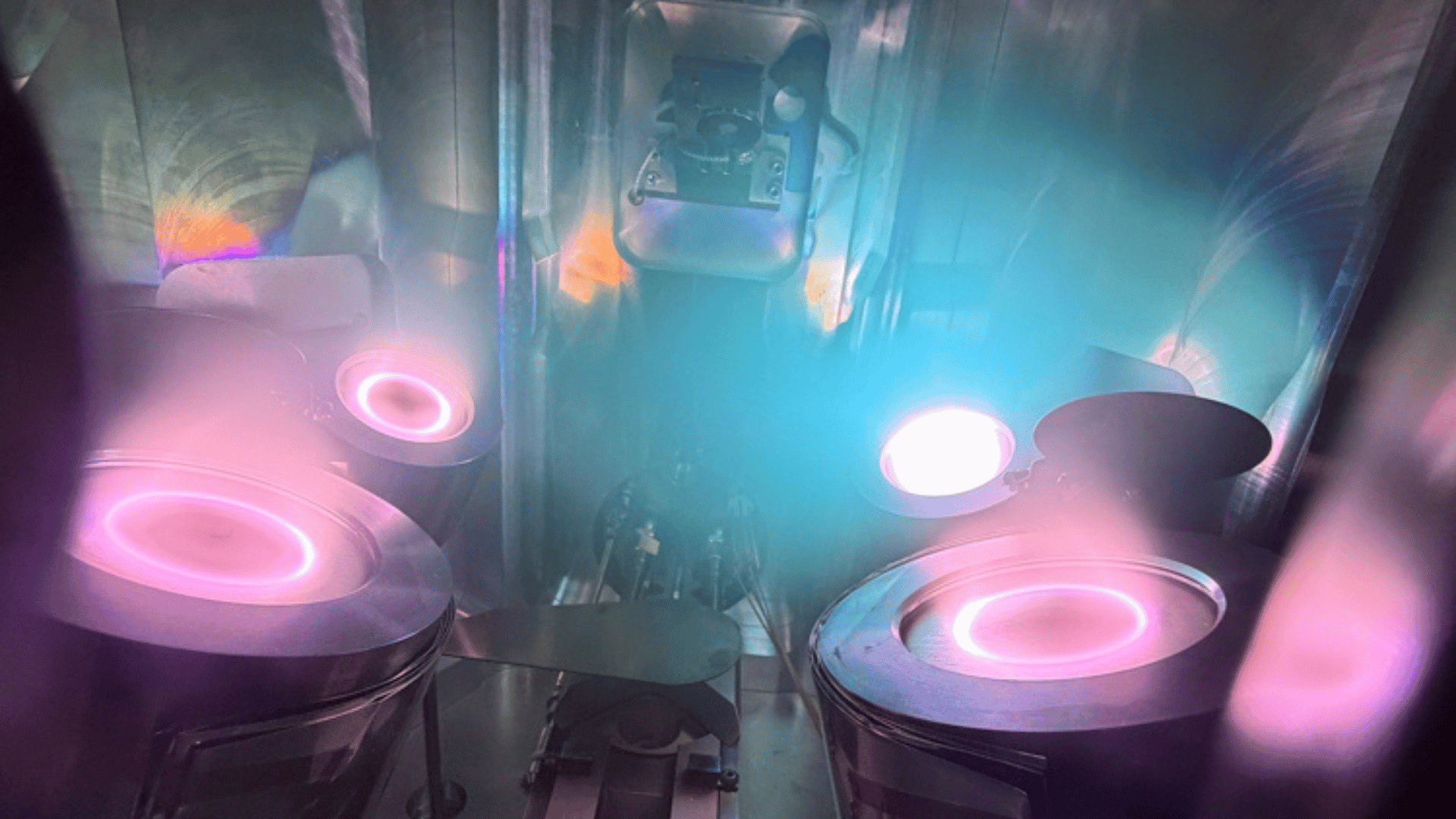

The Additive Manufacturing Cooperative Research Centre (AMCRC) is backing a project with South Australian company entX to build what is essentially a long-lasting nuclear battery. Called GenX, the device is designed to power equipment in places where humans can’t go to refuel or fix things, like deep under the ocean, remote deserts, or the middle of space.

3D Printing Batteries

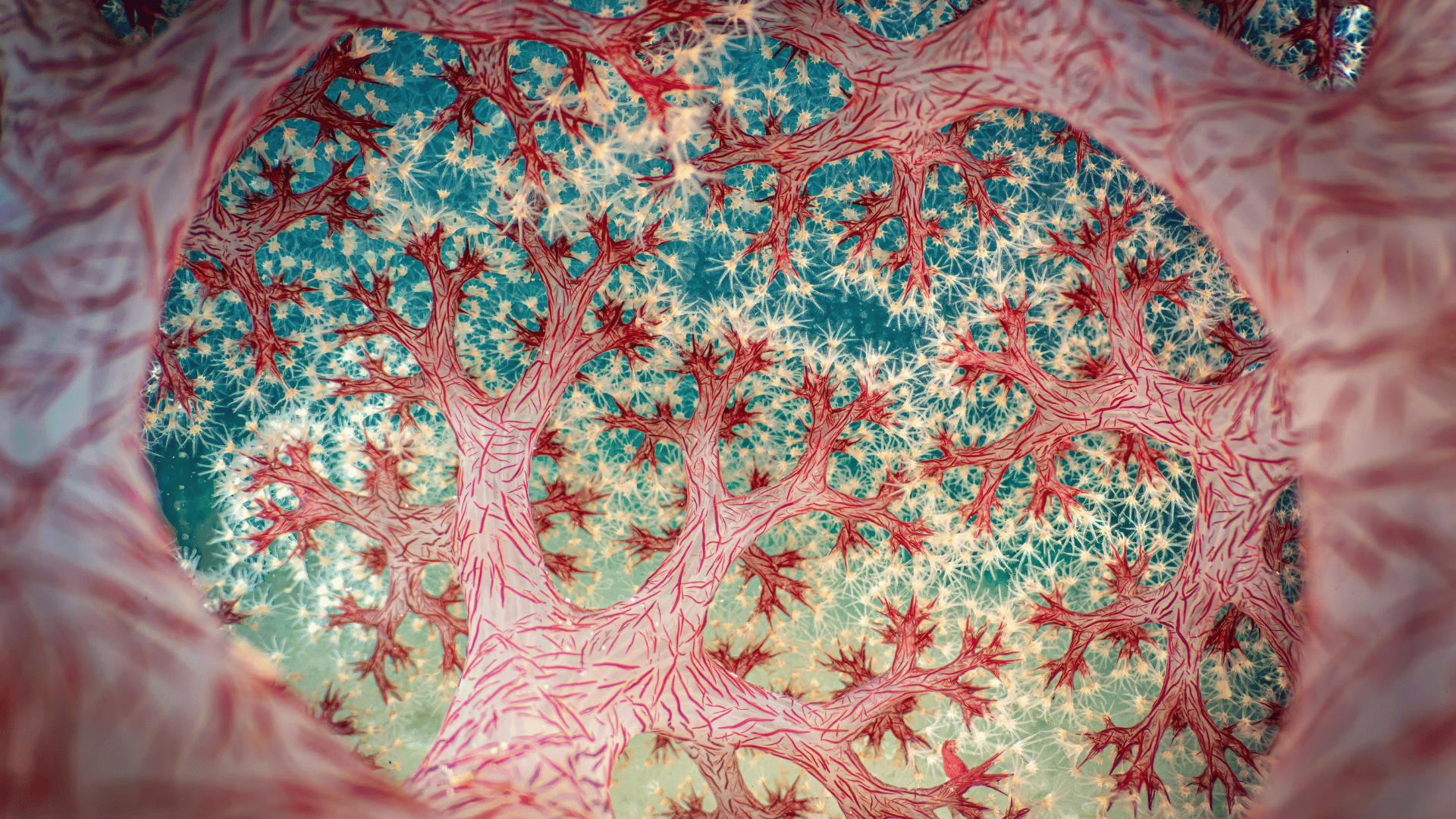

What makes this battery different isn’t just the nuclear tech inside, but how it’s built. The team is using a mix of additive manufacturing (similar to 3D printing) and advanced surface engineering. They’ve figured out how to layer metals and semiconductors at a tiny scale to create ultra-thin films.

The result is a battery that packs a lot of power into a very small frame.

“Reliable, long-life power is one of the biggest bottlenecks facing space, subsea and defence systems,” said Dr. Scott Edwards, the General Manager for Space and Defense at entX. “GenX fundamentally changes what’s possible.”

He added, “By re-engineering betavoltaics as ultra-thin, additively manufactured devices, we’re achieving power densities that were previously out of reach and enabling entirely new mission profiles.”

From the Lab to the Real World

Up until now, this tech was mostly a prototype sitting in a lab at Adelaide University. However, this new $1.8 million project aims to turn it into something that can be manufactured at scale over the next 14 months.

Professor Drew Evans helped develop the prototype. He believes the way they are building these batteries is what makes them stand out.

“This is not an incremental improvement – it’s a genuine step-change,” Evans said. “By combining novel semiconductor deposition methods with additive manufacturing and surface engineering, we’ve demonstrated betavoltaic devices with power densities that simply weren’t achievable using conventional approaches.”

By the time the project finishes, the goal is to have a working demonstrator ready for customers.

“This $1.8m project is a clear example of how additive manufacturing can take breakthrough research and make it manufacturable at scale,” Simon Marriott from the AMCRC concluded.