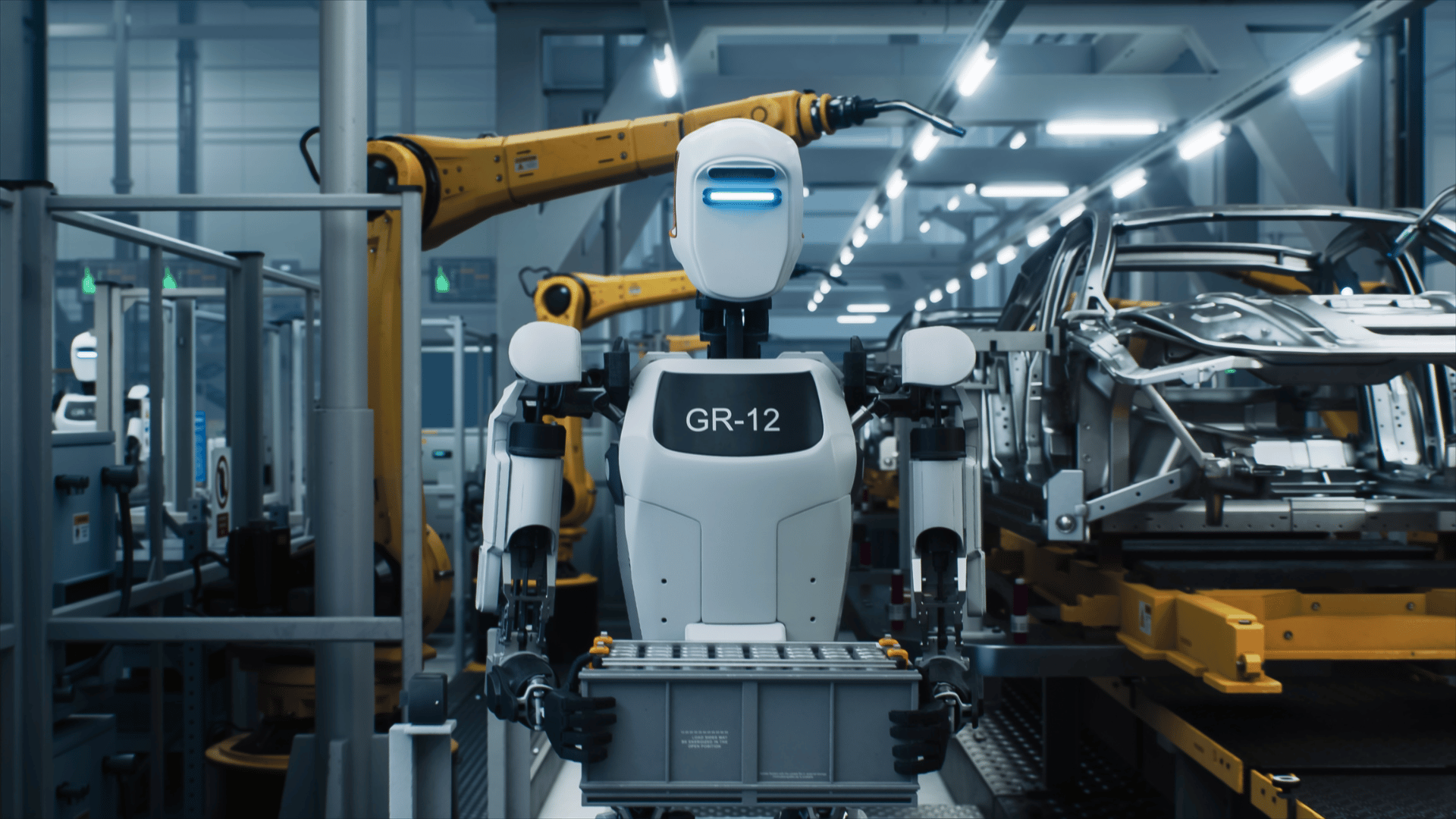

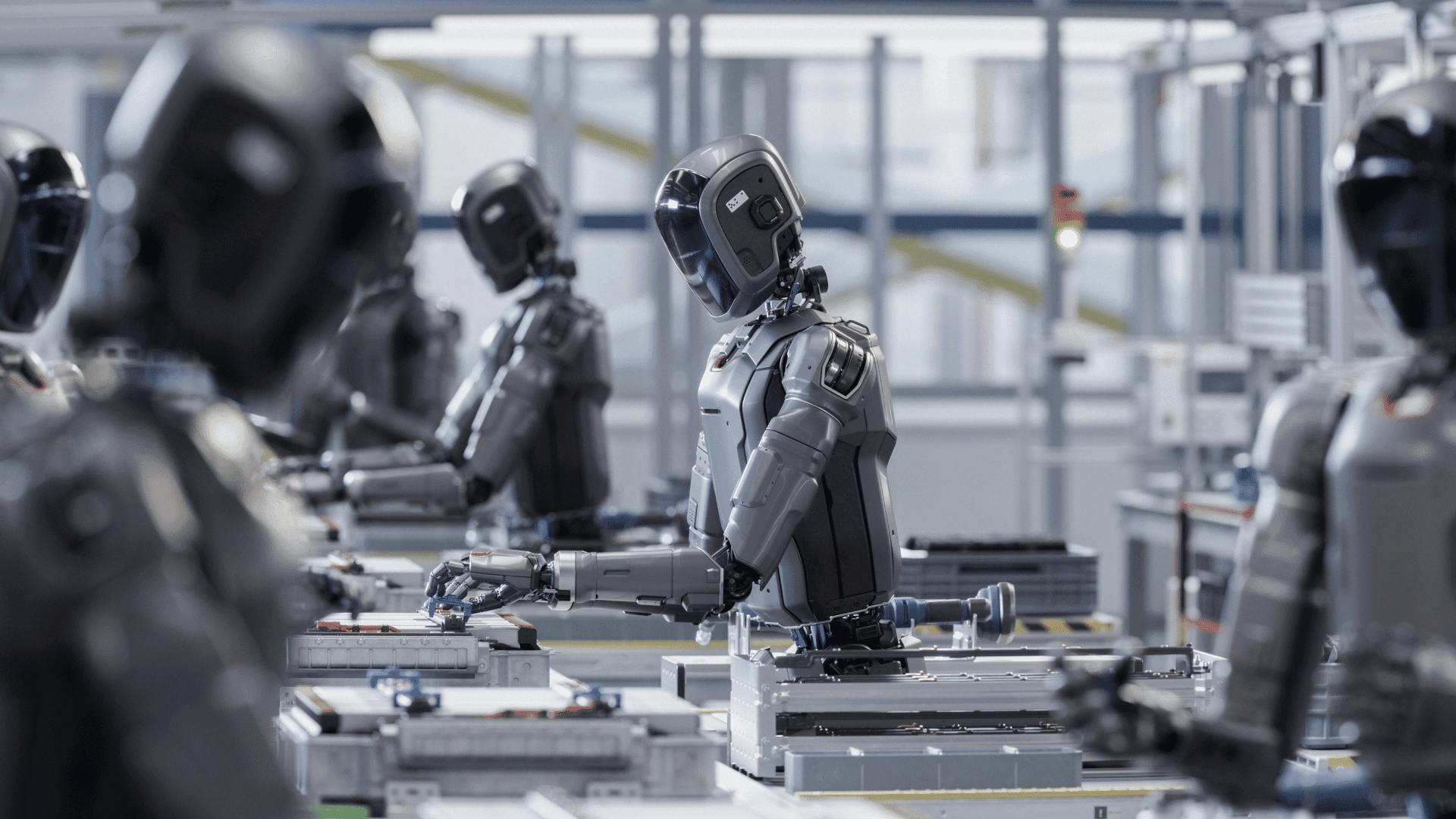

Though humanoid robots used to simply be a spectacle at trade show demos, they’ve now officially moved to active duty on assembly lines across the U.S. and Japan. But what are the benefits of creating machines that resemble humans?

The “Brownfield” Advantage

The biggest hurdle to automation has always been the factory itself. Most existing plants are “brownfield” sites—facilities designed specifically for the human form, with narrow walkways, stairs, and manual workstations.

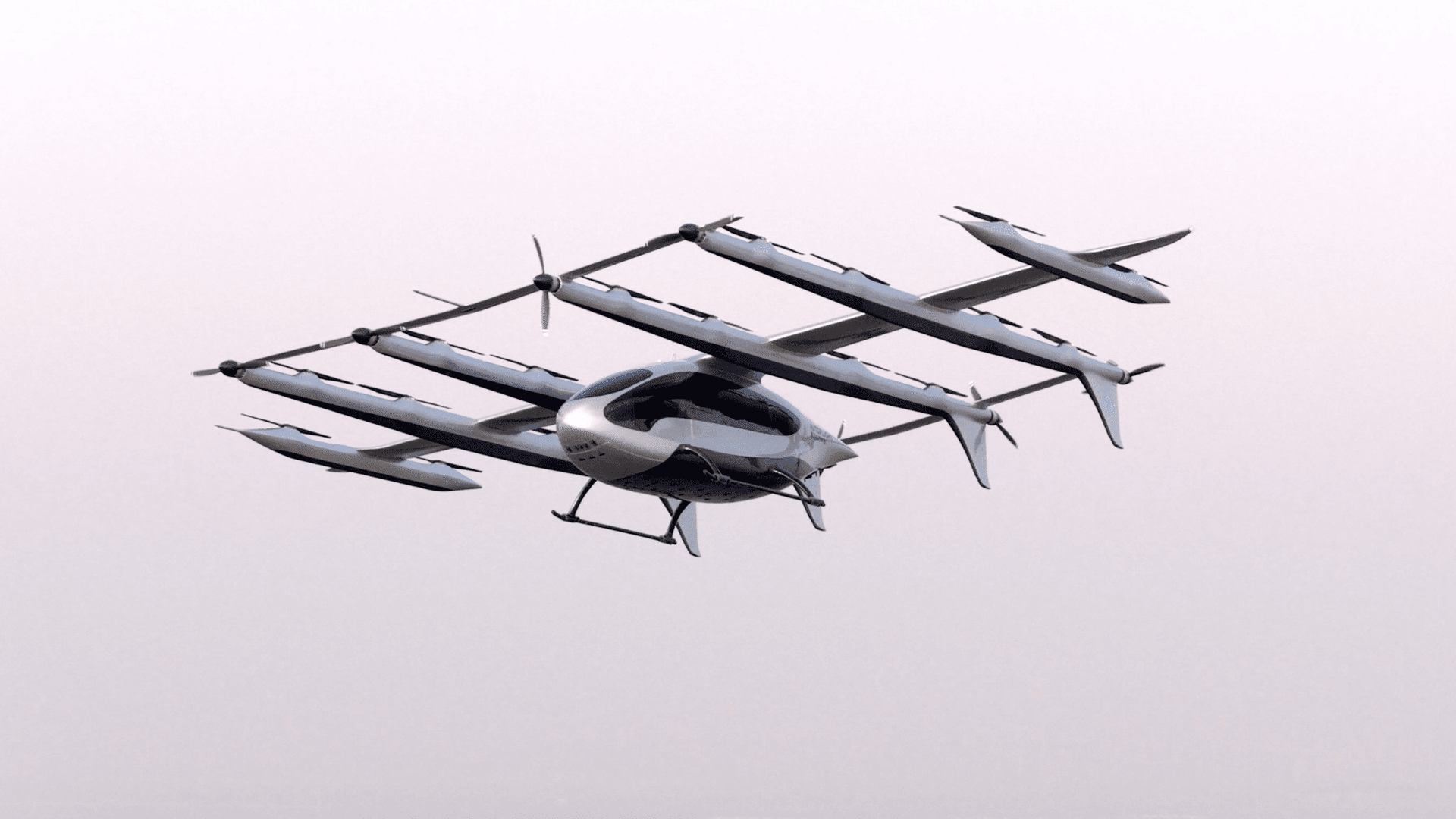

Traditionally, installing a robot meant ripping out floors and installing massive safety cages. Humanoid robots like Apptronik’s Apollo or Figure AI’s Figure 02 solve this by fitting into the world without changing it.

Making a robot human-shaped means the factory layout doesn’t need to be adjusted to accommodate a machine because they can walk and reach, and move things the way humans do. This benefits rapid scaling and system versatility, meaning a robot could be rerouted to different areas and tasks remotely via software based on production needs.

BMW’s 1,000-Hour Milestone

BMW completed a pilot at its Spartanburg, South Carolina, plant in 2025, where a facility integrated Figure 02 humanoid robots into the body shop to handle sheet metal parts. Spanning an 11-month trial, the robots recorded 1,250 hours of runtime, loading more than 90,000 parts with a 99% success rate.

The robots performed “pick-and-place tasks” with 5mm precision, which means they can match the cycle times required for high-speed automotive production.

Tackling the Tough Jobs

Humanoid robots are being used in industries like chemical handling, for example. While the robots work in dangerous, fume-heavy environments, humans are relocated to jobs like managing toxic adhesives and sealants.

Rather than tackling hazardous “single-purpose” tasks, humans are being used as robot fleet managers to focus on quality control and system optimization. Humanoid robot workers also alleviate ergonomic strain from human workers, such as heavy lifting in tight spaces or tasks involving “overhead assembly”.

The Assembly Line of the Future

As we look toward 2026, the goal isn’t to replace humans, but to create a hybrid workforce. With the integration of physical AI, these robots are learning to recover from slips, navigate around moving forklifts, and even communicate with human coworkers using natural language.

The factory of the future isn’t a dark, human-less void. It’s a collaborative space where the most dangerous and repetitive tasks are handled by silicon and steel, leaving the complex problem-solving to us.