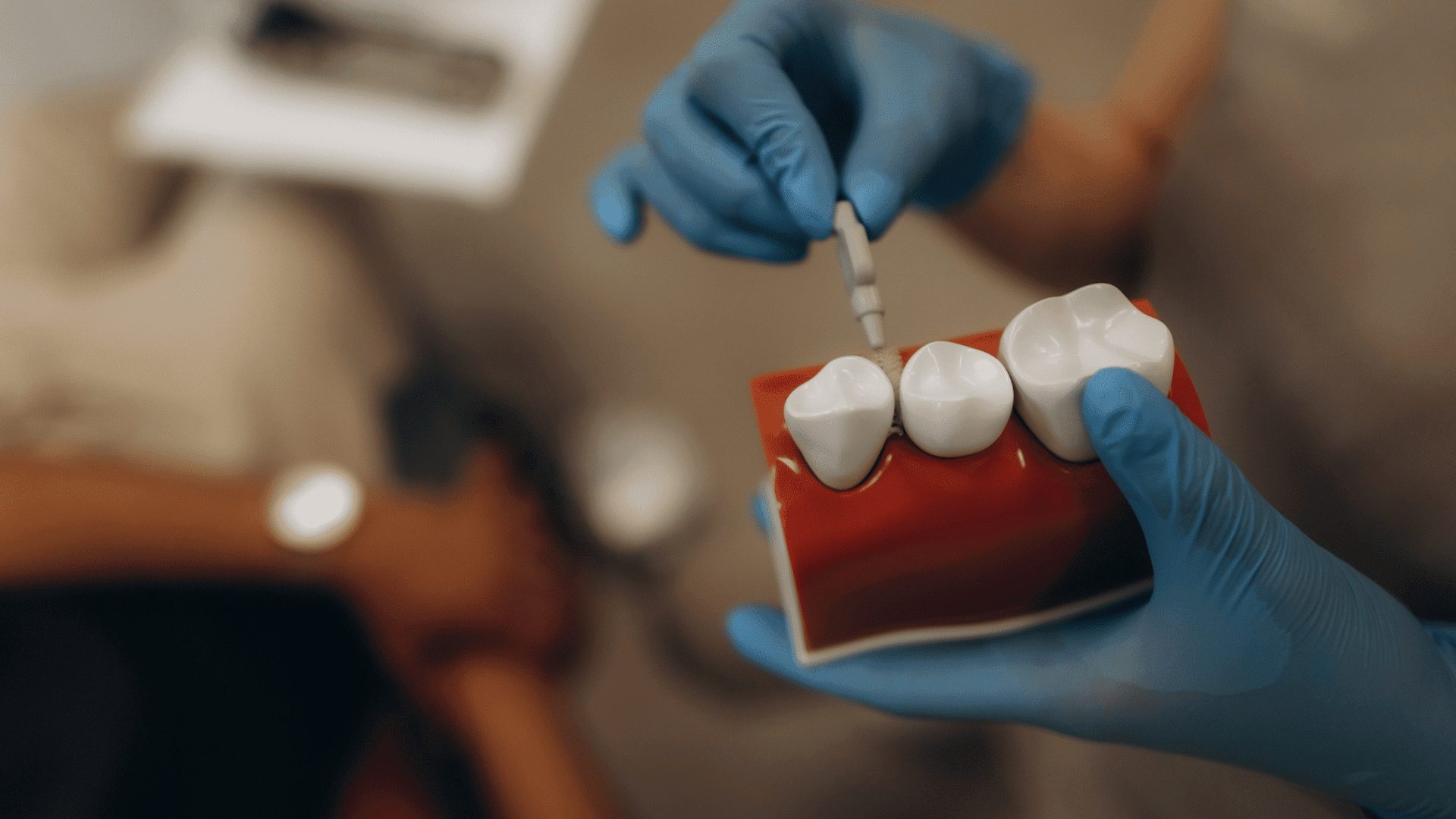

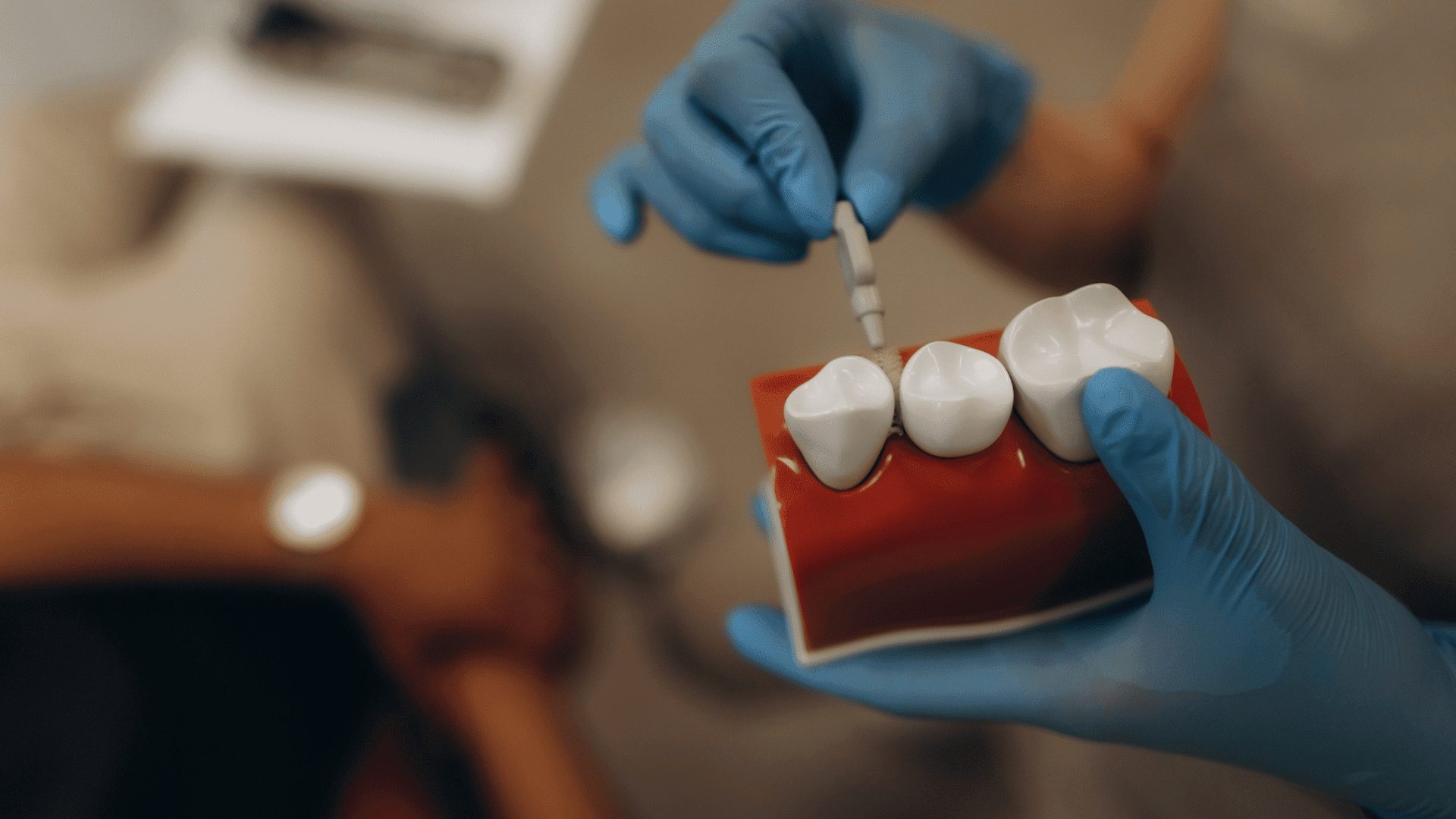

The idea of having bones made of glass is used to describe someone who is fragile or frequently prone to injuries, but could bones actually be replaced by glass? Researchers are developing a 3D printable bio-active glass that could be used as a bone replacement.

Glass and bone are both capable of resisting compression better than stretching. The main ingredient in glass is silica, which can be shaped freely in liquid form. That means this technology could be used to make custom-fitted implants to fix damaged sections of bone.

Bio-Glass Bone Replacement

The new glass appeared to support bone growth longer than plain glass, nearly matching the strength of a leading dental implant material in animal tests. There are manufacturing challenges in terms of cost and safety, as 3D printing glass requires plasticizers and heating to around 2,000 degrees Fahrenheit.

Advertisement

Researchers led by Jianru Xiao, Tao Chen, and Huanan Wang sought to overcome those challenges by combining oppositely charged silica particles with calcium and phosphate ions. This mixture formed a printable gel that could be hardened at a less intense 1,300 degrees Fahrenheit.

To trial the new formula, the team tested the new bio-glass, plain silica glass, and commercial dental bone substitute in rabbit skull repair. Though the commercial product offered faster early growth, the bio-glass appeared to be more durable. Additionally, after eight weeks, most bone cells had attached to the bio-glass scaffold, whereas the plain glass showed little growth.

The new method also uses inorganic self-healing colloidal gels made from silica-based nanospheres that attract each other electrostatically. Through a process called low-temperature sinitering, researchers were able to 3D print strong glass structures without additives and at a lower temperature.

The material reportedly sustained bone growth longer than existing options. Researchers believe the material has applications ranging from machinery to energy industries.

“This ‘green’ inorganic 3D-printing strategy enabled cost-efficient and bioactivity-preserved fabrication of bioglass-based bone substitutes, which led to improved in vivo osteogenesis and osteointegrity,” researchers wrote.