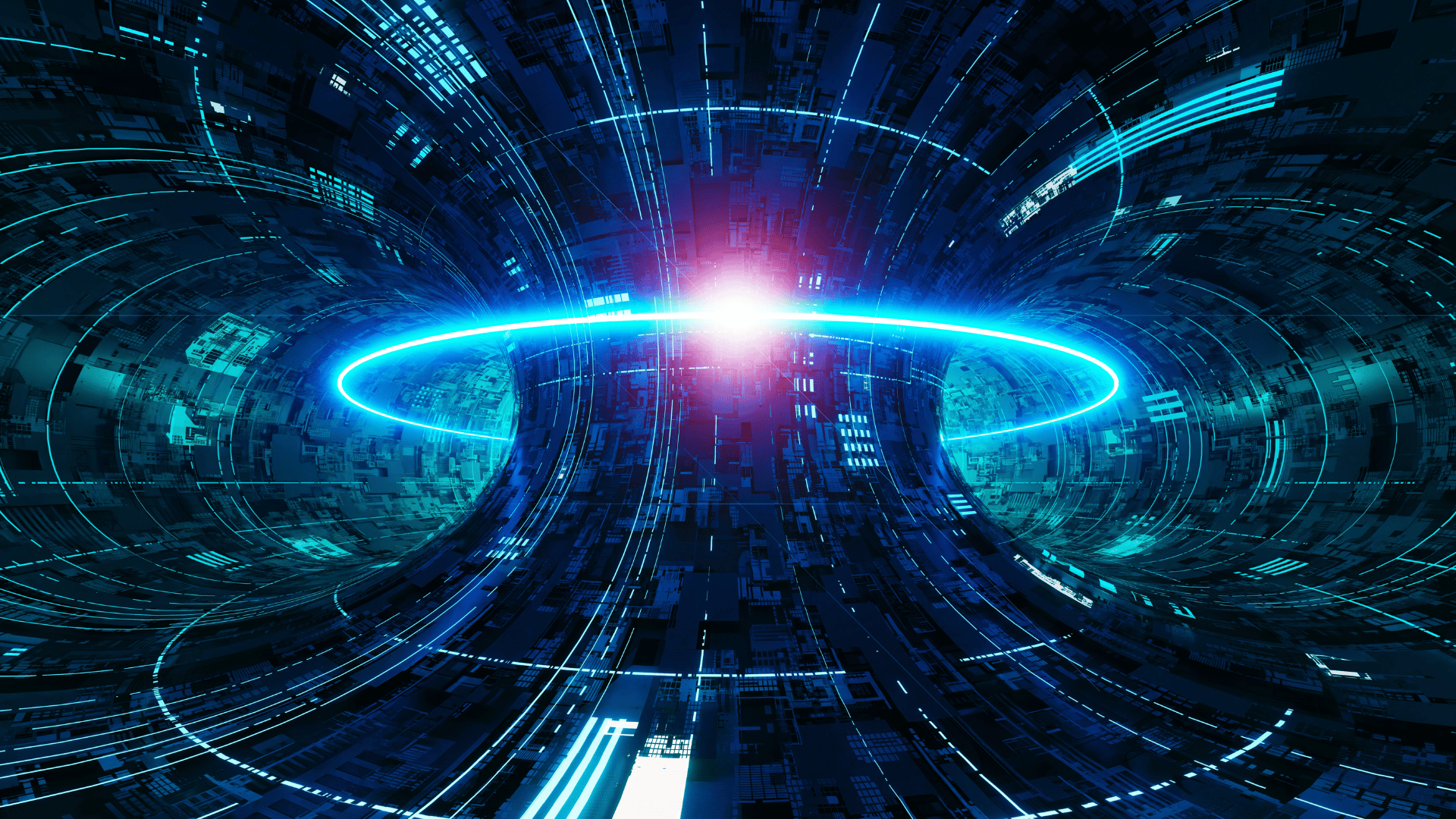

Engineers and scientists prioritize building safe and efficient nuclear reactors. Thanks to a team of MIT researchers, these scientists now have a powerful tool to achieve that. MIT researchers pioneered a method for watching materials degrade in real time in a simulated nuclear environment. According to the team, the breakthrough allows them to observe how corrosion and cracking happen.

As a result, researchers could design more resilient materials that extend a reactor’s lifespan.

Monitoring a Nuclear Reactor in Real-Time

The team is led by researchers Ericmoore Jossou and David Simonne. They used strong X-rays to mimic the destructive effects of neutrons on materials inside a reactor. According to the researchers, they focused a beam onto a sample of nickel, a common metal found in reactor alloys.

Initially, researchers struggled to get the sample right. They stated the nickel would react with the silicon base it was placed on, eventually ruining the experiment. After some trial and error, they found that a thin silicon dioxide buffer solved this problem.

The buffer reportedly had an unexpected but welcoming side effect. Researchers discovered that they could relax the material’s internal strain by keeping the X-ray beam on the sample longer. As a result, the process allowed them to capture accurate, 3D images of the crystal’s structure as it failed.

“If we can improve materials for a nuclear reactor, it means we can extend the life of that reactor,” said Jossou. “It also means the materials will take longer to fail, so we can get more use out of a nuclear reactor than we do now.”

He added, “The technique we’ve demonstrated here allows to push the boundary in understanding how materials fail in real-time.”

This new method departs from the traditional approach of studying material failure after the fact. “Only with this technique can we measure strain with a nanoscale resolution during corrosion processes,” explained Simonne.

The research, published in the journal Scripta Materiala, also yielded a surprising bonus. The team realized they could use the X-ray beam to precisely control the amount of strain in a material. This secondary finding has significant implications for the microelectronics industry, where manipulating strain can enhance a material’s electrical properties.

Looking ahead, the researchers plan to apply their technique to more complex materials like steel and other metal alloys.