While lithium batteries offer a clean energy alternative, they pose significant waste challenges. The wave of expired lithium-ion batteries from first-generation electric vehicles is looming over the world. Finding an efficient way to recycle these batteries is crucial. Specifically, the problem is with lithium iron phosphate (LFP) batteries. LFP batteries are commonly used for E-buses and E-delivery vans. To make matters worse, LFP batteries typically age out after about a decade.

Traditional recycling methods are too costly to be economically viable. Researchers say they often yield little value beyond lithium. However, a team of researchers at the University of Wisconsin-Milwaukee (UWM) developed an innovative alternative recycling strategy.

Deyang Qu, a professor of mechanical engineering at UWM and a global leader in energy storage research, and his team have pioneered a solution: transforming retired LFP batteries into domestically produced fertilizer. The financial hurdle of current methods provided the initial inspiration.

“Right now, it costs more to recycle the batteries than the value of what we recover,” Qu said. “But if we can turn those elements into fertilizer, we not only reduce waste but also support agriculture in Wisconsin and beyond.”

Turning Lithium Batteries into Fertilizer

The solution hinges on an ion-exchange process. First, the researchers successfully recovered lithium from the LFP batteries using this new technique. The remaining phosphorus, potassium, and nitrogen are all key, high-value ingredients in agricultural fertilizer. The motivation behind creating a high-value product like fertilizer is simple economics and environmental stewardship.

“There are only two options to deal with this kind of waste,” Qu said. “Either the manufacturers or the government will have to pay to dispose of the waste.” He added, “That’s what inspired us to look for an economically sustainable way.”

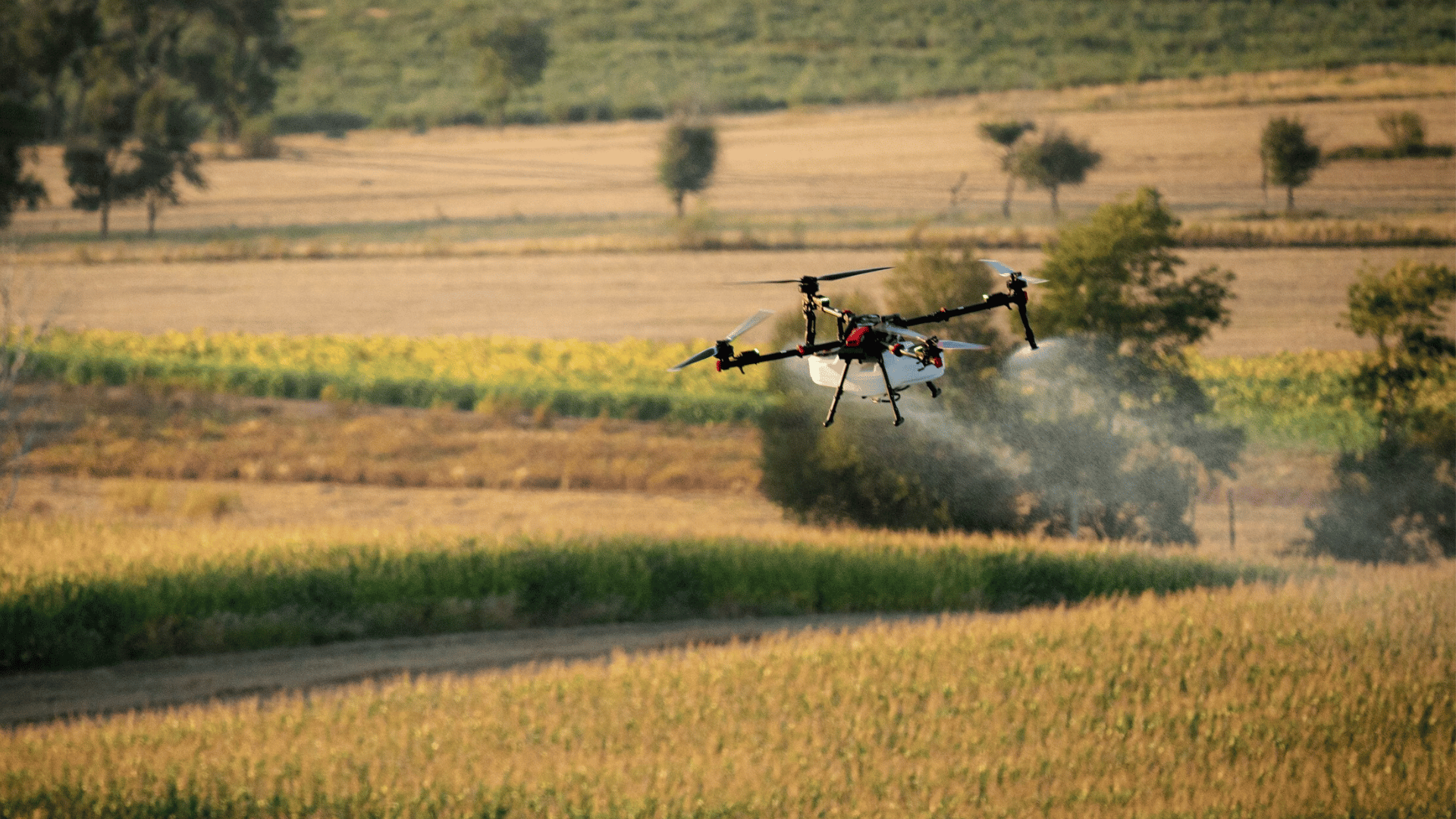

Beyond sustainability, this recycling method promises to establish a ready domestic supply of fertilizer ingredients, reducing reliance on imports and requiring less energy than traditional mining and transport.

With the proof of concept demonstrated through UWM funding and a partnership with the USDA’s Agricultural Research Service, the next steps are to scale up production.

Deyang Qu confirmed that once the recycling and separation phase obtains support, they will “continue collaborating with the USDA to produce enough material for a one-acre tomato crop trial.”