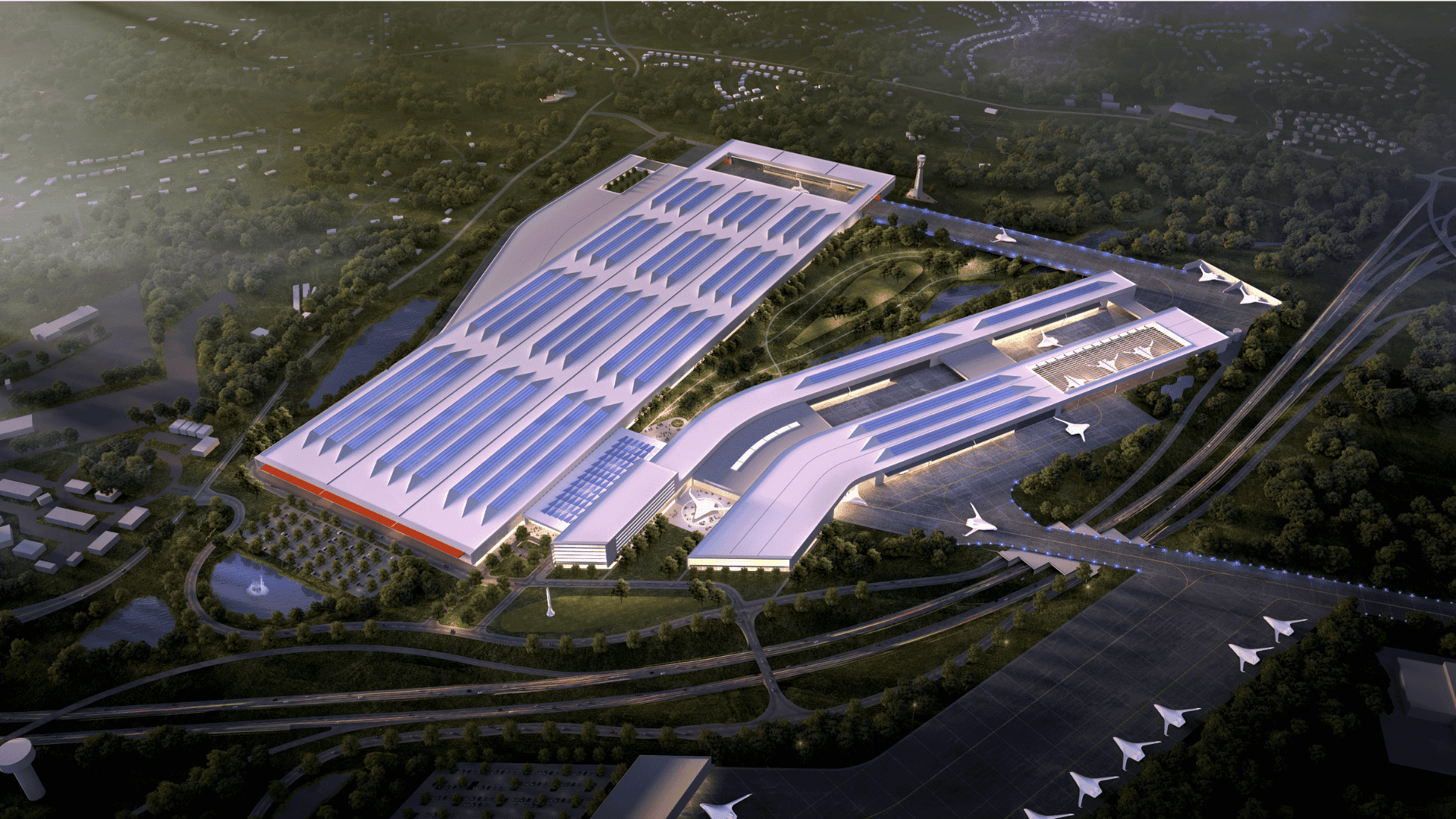

JetZero recently announced its plan to build its first advanced manufacturing and final assembly facility to produce the fuel-efficient JetZero Z4 airplane. The company claims that the Z4 plane will deliver up to 50% better fuel efficiency due to its design.

“This facility is a critical milestone in bringing our all-wing Z4 to market,” said Co-Founder and CEO Tom O’Leary.

One Step Closer to a Fuel-Efficient Jet

JetZero’s announcement puts them one step closer to their production goal, promising many benefits to the Greensboro, North Carolina, community, where the facility will be built.

“The new site will create more than 14,500 jobs,” the press release states. “Delivering positive economic impact on the region and providing opportunities for collaboration with academic and vocational training institutions.”

According to JetZero’s release, once complete, the facility will be capable of producing up to 20 Z4 airplanes per month. However, that is projected to happen when the facility is at its full run rate, which isn’t expected until the 2030s.

Until then, JetZero is taking an innovative and efficient approach to building and running the new facility. “JetZero is taking a clean-sheet approach to designing and building the factory,” the company stated. Doing so includes an ongoing partnership with Siemens. Through the partnership with Siemens, “JetZero is designing the greenfield factory to leverage the latest digital and industrial AI tools to ensure the most efficient and cost-effective production and operating model.”

Additionally, the two companies will work together on the design/build/test model for the Demonstrator aircraft, a full-scale prototype slated for first flight in 2027.

“JetZero’s upcoming facility, powered by Siemens technologies, demonstrates that revitalizing American manufacturing is more than just a vision—it’s becoming reality,” said Barbara Humpton, President and CEO, Siemens USA.

A Fuel-Efficient Airplane

The most frequently mentioned and significant benefit is the Z4 airplane’s 50% reduction in fuel burned. This benefit comes from the plane’s blended-wing-body (BWB) design, which reportedly minimizes drag and maximizes lift.

In addition to the BWB design, there is potential for the aircraft to run on hydrogen fuel or other alternative sustainable aviation fuels (SAF). However, the company focuses on the design until the alternative fuel infrastructure advances.