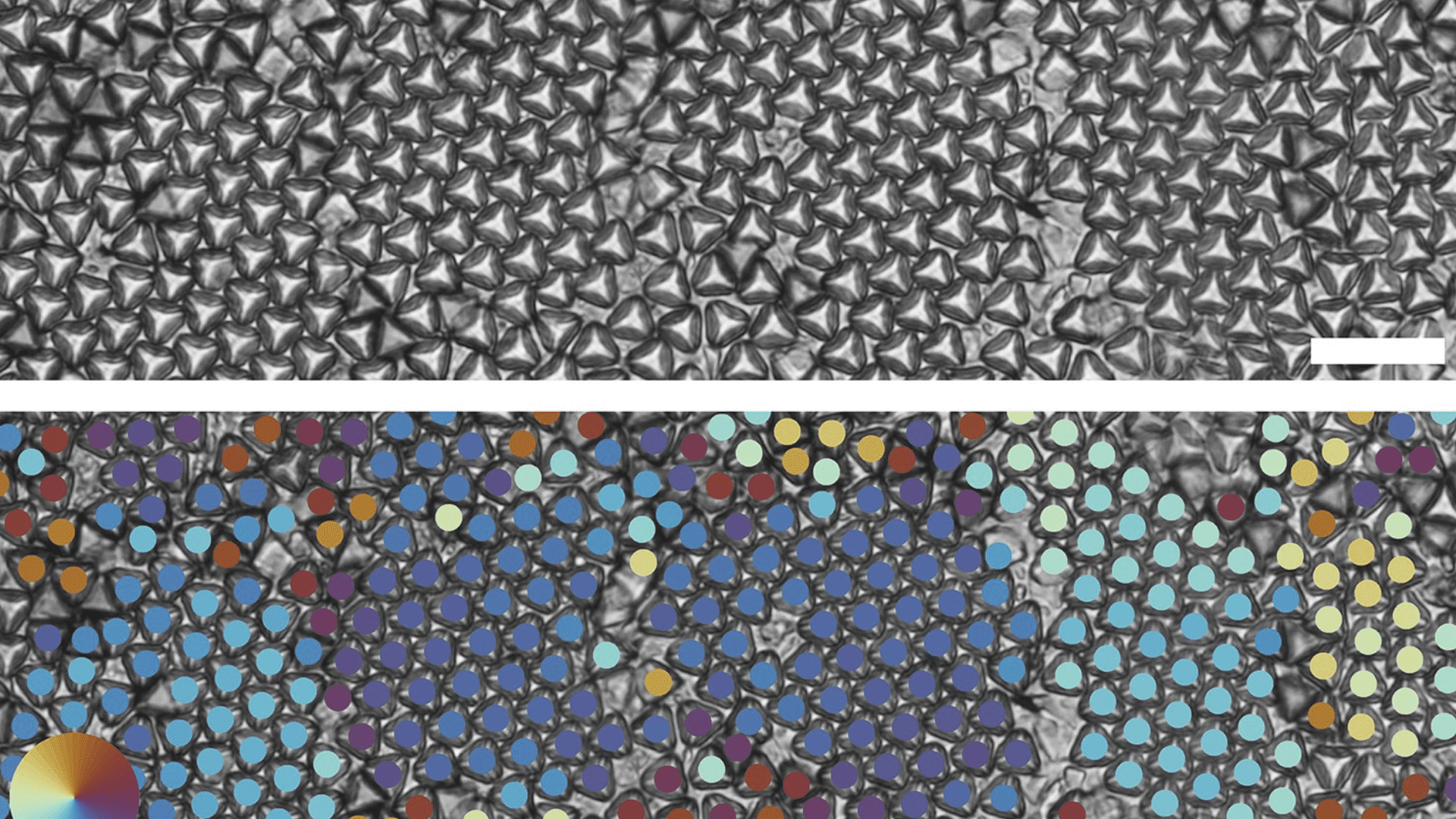

Researchers from Stanford University 3D printed nanoparticles with unique, shapeshifting abilities. The 3D-printed shape of the nanoparticles is recognized for its potential to change form instantaneously. However, they are difficult to fabricate with conventional manufacturing techniques.

The promising shape of the nanoparticles is called Archimedean truncated tetrahedrons (ATTs). The researchers published their findings in the journal Nature Communications.

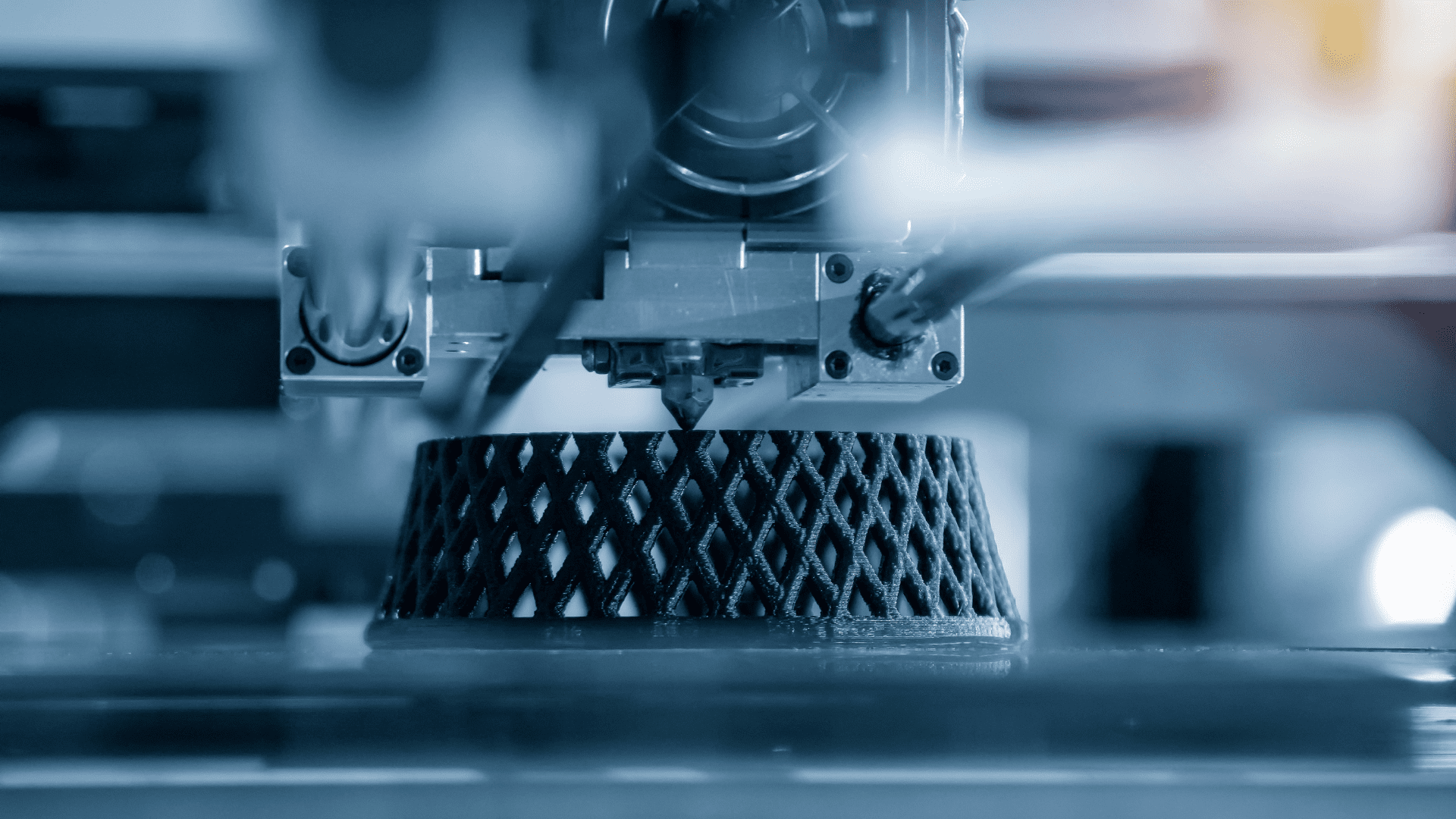

3D Nanoprinting

Wendy Gu is an assistant professor of mechanical engineering at Stanford University and the lead author of the study. Gu said, “We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off.”

Once the team 3D printed the particles, Gu said they successfully self-assembled into different crystan structures. They believe the materials can shape between different phases in a matter of minutes. According to researchers, the particles do this by applying different external stimuli. It’s similar to an atomic arrangement that turns tempered steel into iron.

The team hopes their research can enable significant innovations in the worlds of engineering and applied sciences.

For example, the nanoparticles could help develop new solar panel coatings that change throughout the day to increase energy efficiency. Another idea researchers have is using hydrophobic films to prevent airplane windows from fogging or icing up. Additionally, they believe there is potential for new computer memory systems.

Gu added, “If we can learn to control these phase shifts in materials made of these Archimedean truncated tetrahedrons it could lead in many promising engineering directions.”

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

How Researchers Did It

Researchers theorize that ATTs are the most effective geometries for the production of shapeshifting materials. Although they successfully created them in computer simulations, these materials pose challenges for researchers in terms of physical fabrication. The Stanford team is not the first to fabricate large quantities of nanoscale ATTs but they are the first to achieve this with 3D nanoprinting.

During the study, researchers used a technique that creates small features in a photosensitive material called two-photon lithography. They did this to fabricate 50,000 particles on a Phototonic GT 3D printer. Once the team prints the particles, they mix them into a water solution and put them in a well plate. The nanoparticles assemble into two distinct geometric structures when titled at a 5 and 10-degree angle.

First, there is a hexagonal pattern researchers believe is the first time this particular hexagonal phase has been recorded in literature. Second, is a crystalline quasi-diamond formation. Researchers say there is more promise with this one. The structure is a sought-after configuration within photonic research. Standford’s team of researchers believe it could unlock novel scientific advances.

They want to test whether adding a magnetic field, electric currents, and heat could enable the 3D particles to rearrange and change between phases. Moreover, these capabilities could offer significant value in aerospace, energy, and electronics.

“Right now, we’re working on making these particles magnetic to control how they behave,” Gu said, “The possibilities are only beginning to be explored.”