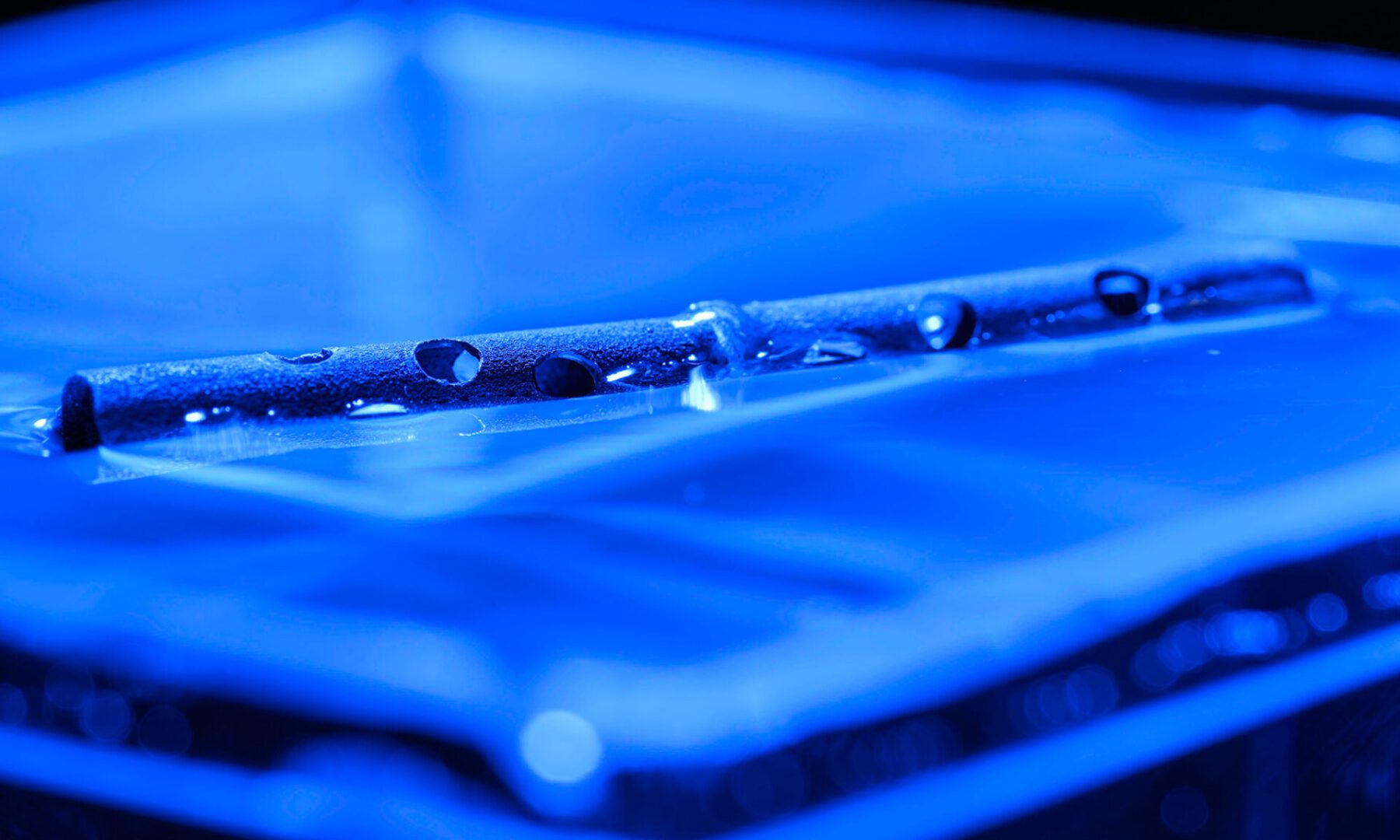

Researchers from the University of Rochester have created metal tubes that can float despite extreme physical damage.

The knowledge of materials science research is at the core of this flotation property. The research team led by Professor Chunlei Guo at the University of Rochester’s Institute of Optics has used laser etching to create water-repellent properties in aluminum.

Laser Etching Creates Permanent Air Pockets

The laboratory is using high-powered laser systems to change the physical properties of aluminum tubes. The tubes emit pulses lasting one quadrillionth of a second to prevent the metal from melting. Laser etching creates microscopic pits on the surface that serve as air containers.

The 2026 study by the researchers used lasers that were seven times more powerful than those used in 2019. This increase in power allows them to etch larger areas on the metal’s surface. As a result, the development has expanded the possibilities of producing these durable metal tubes.

Biological Blueprints

Nature provides the fundamental mechanics behind this buoyancy property. The research team studied species such as the diving bell spider and fire ants to understand how these animals capture air.

The microscopic pits in the metal tubes function similarly to the fine hairs of a diving bell spider. The air bubble created by these tubes provides the upward force needed to float the tube on water.

Etched metal surfaces employ the Cassie-Baxter model, which explains the interactions between a liquid and a solid surface. This model explains how liquid sits atop a roughened surface without penetrating the grooves.

Internal Dividers Allow the Tubes to Withstand Turbulence

A unique design feature allows these metal tubes to withstand the toughest ocean conditions.

Previous designs of the tube could lose buoyancy when turned to an extreme angle. These tubes feature a physical divider within the tube that traps the air bubble in place.

The divider acts as a physical block that keeps the air bubble centered within the tube. As such, regardless of the tube’s orientation in the water, it can continue floating.

This flotation mechanism allows these metal tubes to thrive in turbulent sea conditions. Tests from Professor Guo’s laboratory show no degradation in buoyancy despite exposure to rough conditions.

Structural Damage Does Not Affect Tube Flotation

The research team also conducted experiments to find the limits of this buoyancy system.

The research team drilled holes into the aluminum walls of the tube. Despite this extreme damage, the tube continued to float on the water’s surface. Due to the air trapped within the non-damaged regions of its etched surface, the tube’s buoyancy remained functional.

This performance is better than most ships’ hulls, which sink after a single puncture.

The superhydrophobic effect will last permanently due to its etching into the metal structure.

Rafts Built From These Tubes Can Generate Electricity From Ocean Waves

Additionally, these metal tubes can generate electricity.

Rafts made from these tubes feature organic photovoltaics that can harvest energy from ocean waves to generate electricity.

What’s Next for This Research Team?

The research team aims to test these tubes in open ocean environments. Other applications include using this etching process on other parts of ships and marine vessels.

The study will appear in the 2026 Advanced Functional Materials publication under the article titled, “Geometry-Enabled Recoverable Floating Superhydrophobic Metallic Tubes.”