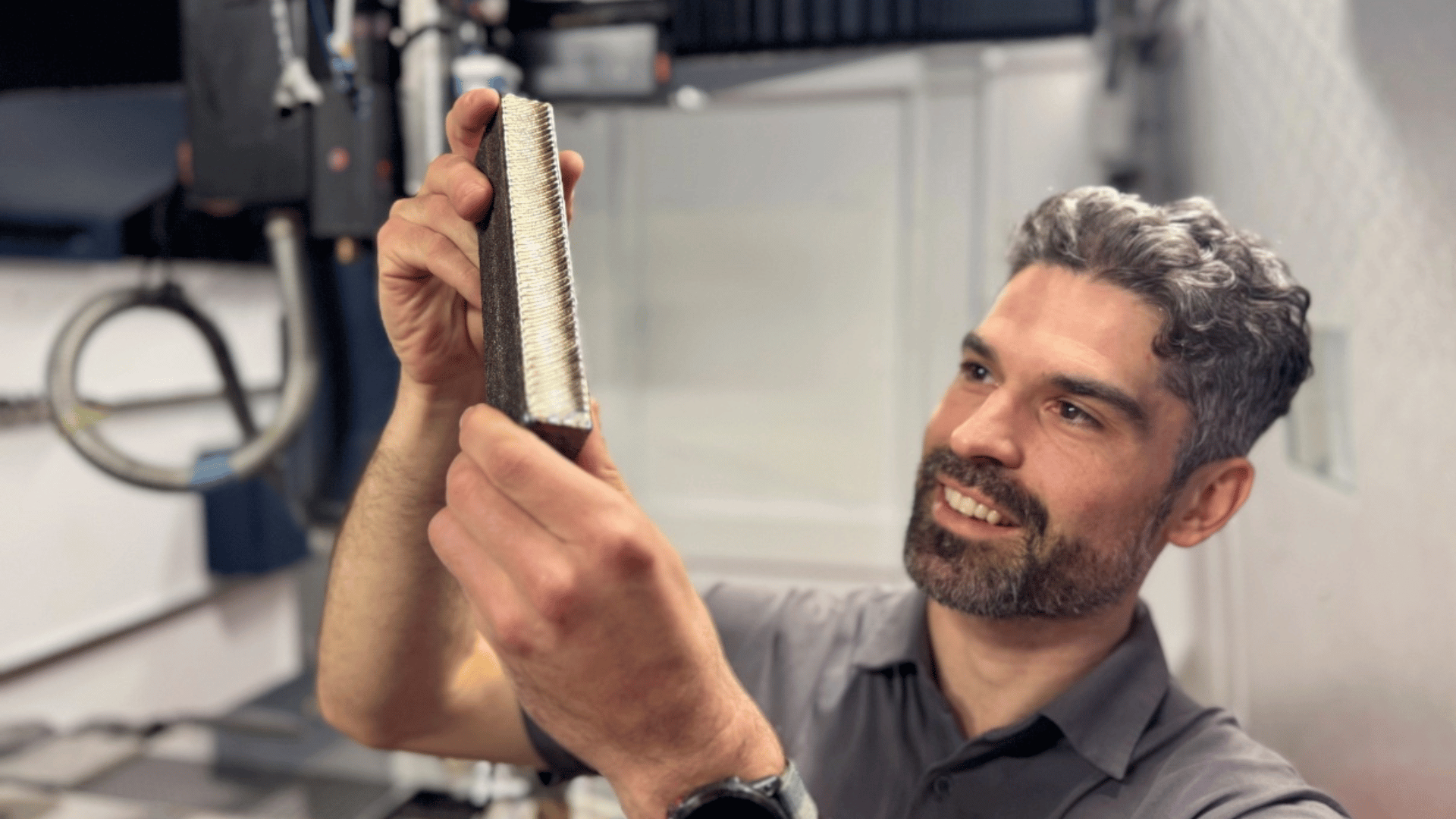

Another breakthrough in additive manufacturing has been achieved, this time in the development of a new titanium alloy for 3D printing that is stronger and more cost-effective than current standards. Researchers at RMIT University in Australia announced their breakthrough, which could pave the way for a new generation of aerospace and medical device components.

A Stronger, More Affordable Titanium Alloy

According to researchers, the new alloy replaces expensive vanadium with readily available and less expensive alternative materials. The study’s lead author, Ryan Brooke, highlighted 3D printing’s potential. “3D printing allows faster, less wasteful, and more tailorable production yet we’re still relying on legacy alloys,” he said. “It’s like we’ve created an aeroplane and are still just driving it around the streets.”

According to Brooke and his team, the innovation’s new design framework is key. They say it provides a “clearer” method for predicting and controlling the printed grain structure of metallic alloys. The new alloy prints more evenly, reportedly improving strength and performance. Additionally, it avoids the column-shaped microstructures that create even mechanical properties.

Brooke says their work solves two major industry challenges. The new alloy is reportedly 29% cheaper to produce than standard titanium. In addition, it’s stronger and more ductile, which means it can be deformed without losing toughness.

“What I heard loud and clear from end users was that to bring new alloys to market, the benefits have to not just be minor incremental steps but a full leap forward, and that’s what we have achieved here,” Brooke added.

RMIT and the research team focus on further developing and commercializing the technology.

“We are very excited about the prospects of this new alloy, but it requires a team from across the supply chain to make it successful,” Study corresponding author Professor Mark Easton said. “So, we are looking for partners to provide guidance for the next stages of development.”

The full research and the findings are published in Nature Communications.