Whether they’re hidden in your Easter basket or you’re checking out the newest flavors at the grocery store, the sugary chicks known as PEEPS® are almost synonymous with the holiday itself. We spoke with Caitlin Servian, PEEPS® Brand Manager, about the flavor creation, manufacturing process, and sustainability practices behind everyone’s favorite Easter candy.

Tomorrow’s World Today (TWT): Where and who came up with the Peeps concept?

Caitlyn Servian (CS): PEEPS® are made by Just Born Quality Confections, a family-owned candy manufacturer that has been in business since 1923. Just Born acquired the Rodda Candy Company of Lancaster, Pennsylvania in 1953. Although better known for its jelly bean technology, Rodda also made a small line of marshmallow products that intrigued the Just Born family. A popular three-dimensional marshmallow chick was made by laboriously hand-squeezing marshmallows through pastry tubes. Sam Born’s son Bob, who had joined the company in 1946, helped to mechanize the marshmallow forming process a year after buying the company.

TWT: How does production keep up with the demand of Peeps during Spring?

CS: We have a great planning, operations, and logistics team that works year-round to bring PEEPS® to our fans. Since we have an assortment of colors, shapes, and flavors across seasons, the team works hard to balance when and where each PEEPS® product will be made. They decide when to produce based on the season and product we’re making.

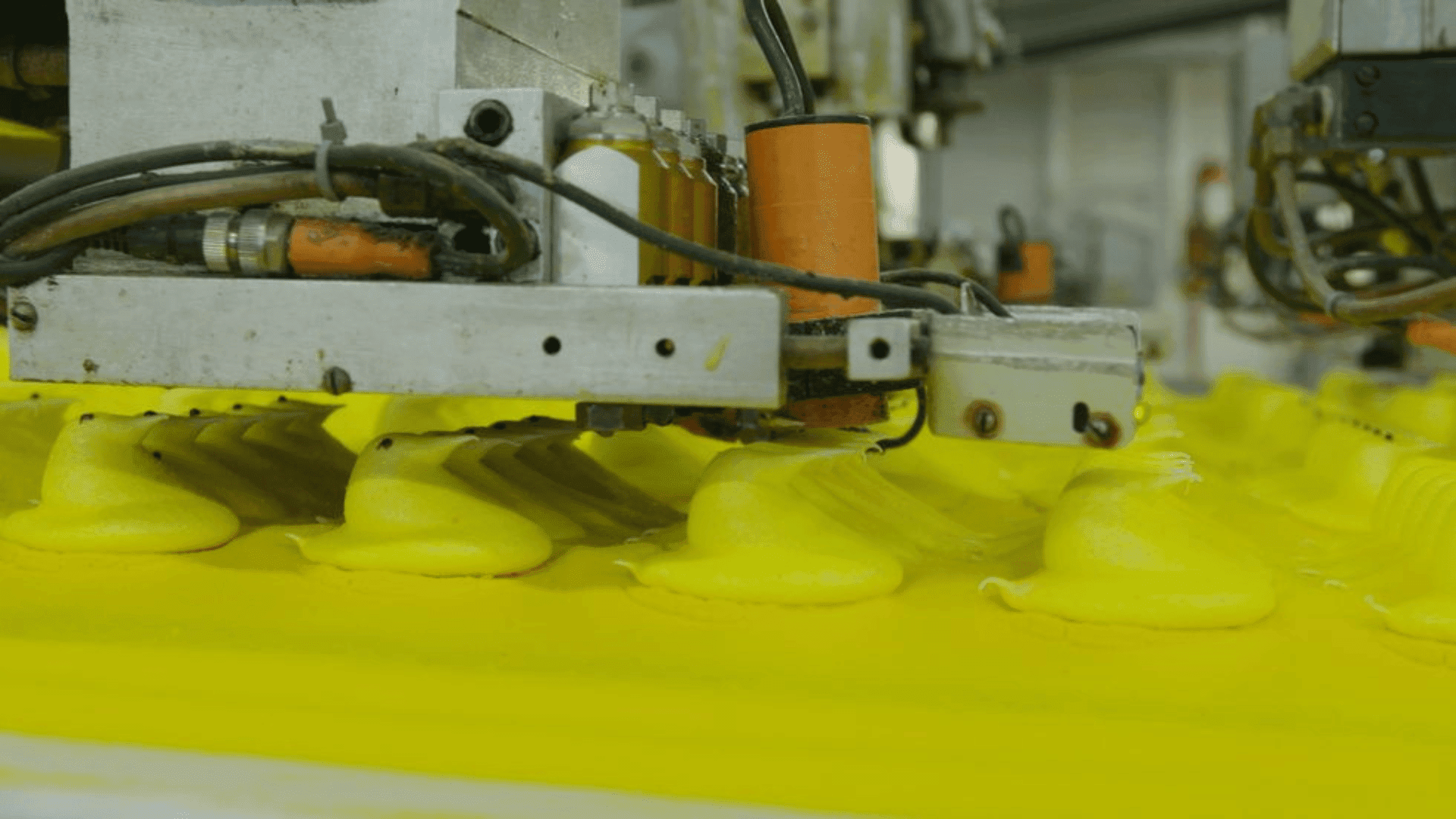

We also have several different production belts with various capabilities, so once we decide what will be made they determine which production belt is needed. All of this is centered around when customers are buying our products, so it ensures that our fans can enjoy PEEPS® for all of their holiday traditions. We make 5.5 Million PEEPS® per day, which is the equivalent of 2 Billion PEEPS® per year.

TWT: How has the candy been able to stand the test of time and remain a staple of Easter?

CS: PEEPS® continue to stand the test of time and remain an Easter staple because they are beloved by so many. For generations, people have received PEEPS® in their Easter baskets. They love this tradition and continue to make PEEPS® a special part of Easter celebrations by passing this down to their children and families. Plus, with a variety of tasty flavors to choose from, as well as fun innovations that bring PEEPS® to life in new and exciting ways, there’s something for every kind of Marshmallow lover to enjoy.

TWT: How have you innovated Peeps over the years?

CS: We continuously work to identify unique yet delicious new products every year while also providing returning fan favorites. This year, we introduced four new tasty Marshmallow creations to our lineup, including PEEPS® Rice Krispies Treats® Flavored Marshmallow Chicks, PEEPS® ICEE® Blue Raspberry Flavored Marshmallow Chicks, PEEPS® Sour Strawberry Flavored Marshmallow Chicks and PEEPS® Delights™ S’mores Graham Cracker Flavored Marshmallow Chicks Dipped in Milk Chocolate.

A part of our business that continues to grow is licensing. Not only do fans love to eat, bake, and decorate with PEEPS®, but they also love the Chick and Bunny as their favorite seasonal characters. We have a growing licensing business which includes everything from plush to clothing, hand soap, activity books, sprinkles, and even at one point, PEEPS® Flavored PEPSI®. This part of the business allows our loyal fans to enjoy the brand through multiple different touch points throughout the season.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

TWT: Peeps used to take 27 hours to make and now they take 6 minutes. Have you added any new technology or practices to your production line recently that have made the peep-making process even more efficient?

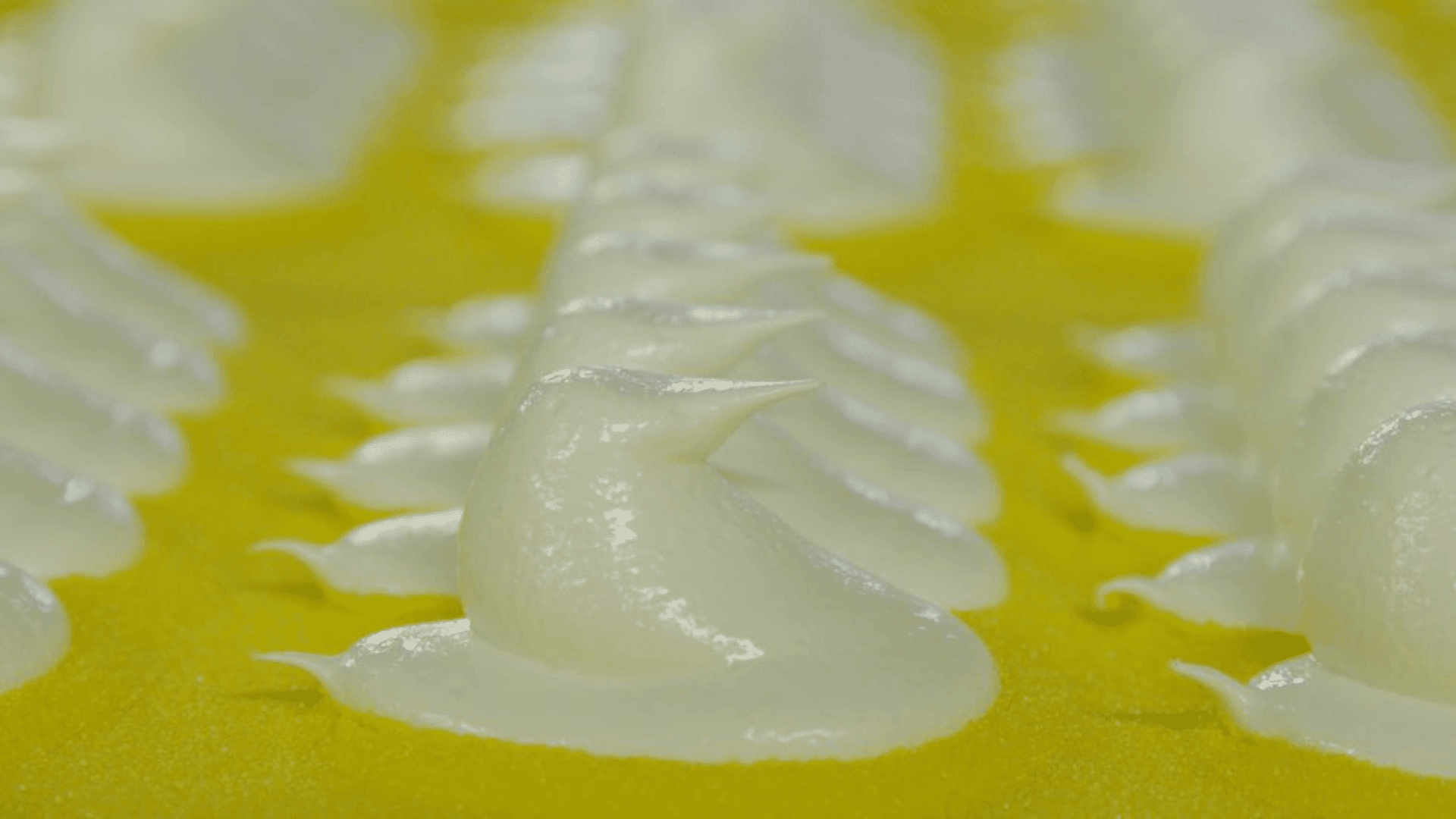

CS: We use a version of the machines today that our founder’s son – Bob Born – invented back in 1954 to automate the PEEPS® production process. We have also integrated technology from Soft Robotics which combines automation and vision-guided software with a gripper made of a soft polymer that molds itself around an object like an octopus tentacle. The spongy fingers can pick up an item without having to determine its weight or center of gravity, and without damaging fragile objects like PEEPS®. This year, we also installed a camera system to review PEEPS® Chick eye decorations. If some of the PEEPS® have a little too much PEEPSONALITY®, we will take them off the production belt to be recycled and used in future batches.

TWT: How is Just Born working to adopt sustainability in their manufacturing practices?

CS: Just Born Quality Confections has always focused on sustainability in our manufacturing practices. In fact, HOT TAMALES® Cinnamon Flavored Chewy Candies were developed as a way to use recycled MIKE AND IKE® Fruit Flavored Chewy Candies. In the PEEPS® production process, nothing goes to waste. One example, any sugar that is on the belt at the beginning of the process and isn’t used is transferred back to the beginning of the process. We are good environmental stewards with a 98% recycling rate and our Bethlehem Facility is landfill-free.

TWT: What are some of your goals for the future for Peeps?

CS: As we look to the future, our goal for the PEEPS® Brand, and at Just Born Quality Confections overall, is to bring sweetness to people’s lives. We want to continue to bring joy to consumers and their families through the classic, iconic PEEPS® Marshmallow, as well as innovative PEEPS® candy offerings and merchandise. As a company, we aim to inspire joy and create moments of sweetness that bring people together, celebrating traditions and making new memories. Our journey forward is guided by a commitment to creativity, community, and the endless pursuit of making life a little sweeter for everyone.