Progress toward carbon-free and reliable energy is driven by innovative concepts that help achieve this goal. Most recently, one of those innovative concepts took a major step forward. General Atomics transitioned its Fast Modular Reactor (FMR) from a conceptual vision into a maturing technology.

Part of this step forward was the demonstration of the feasibility of the FMR’s design, which could redefine how and where nuclear energy can be deployed. Supporting this technological breakthrough is the U.S. Department of Energy (DOE).

What is a Fast Modular Reactor?

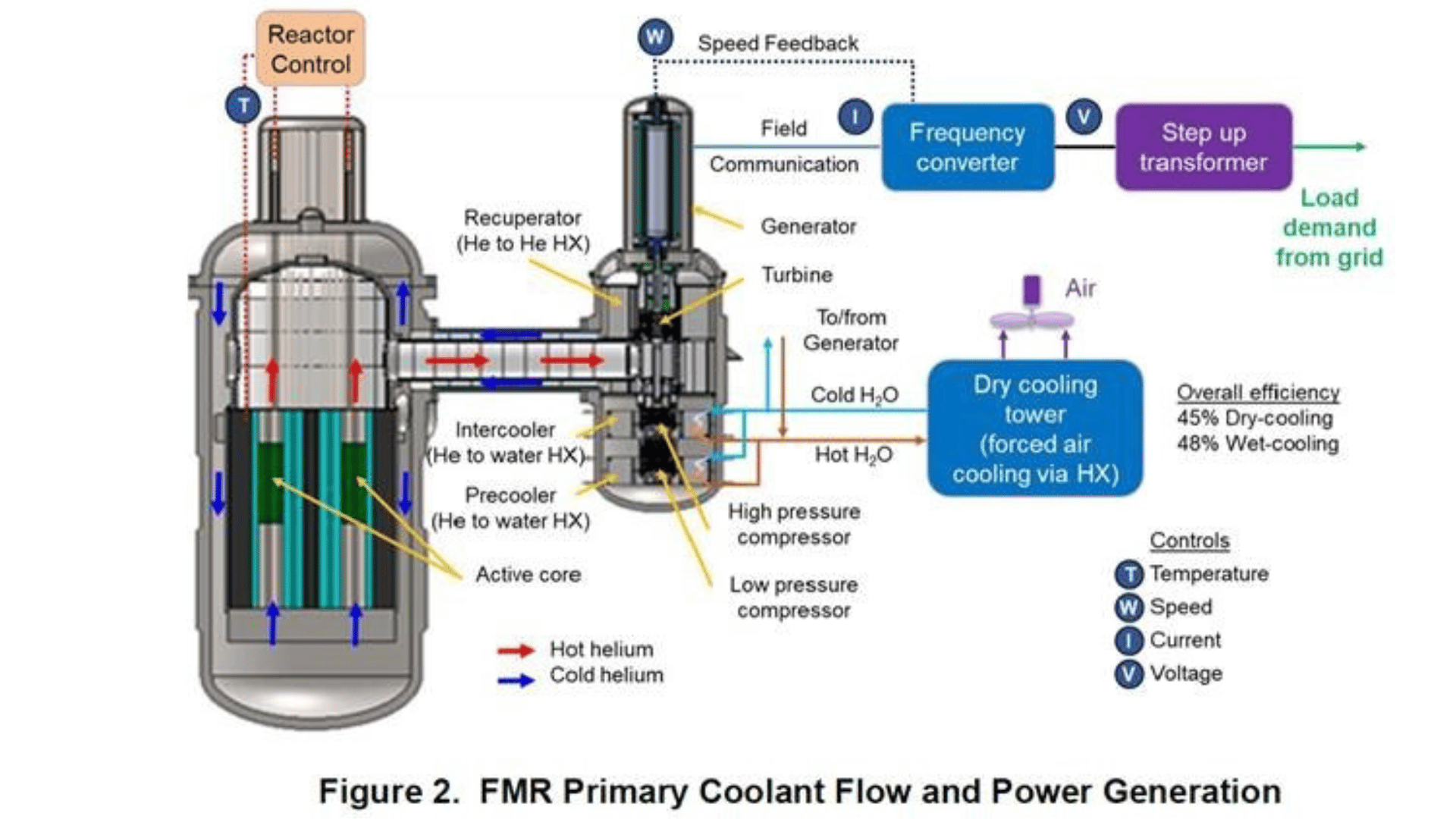

An FMR is a gas-cooled modular reactor designed for efficiency and versatility. Traditional large-scale nuclear plants often require massive footprints and years of on-site construction. However, the FMR is engineered to be built in factories and assembled on-site. This modular approach allows the system to deliver 44 megawatts of power. To put this amount of power into perspective, it’s enough to support small communities or industrial sites. Additionally, all of this power is generated while occupying only approximately 0.2 acres of land.

A standout feature of the FMR design is its use of high-assay low-enriched uranium (HALEU) fuel wrapped in silicon carbide. According to engineers, this advanced cladding can withstand temperatures twice as high as the materials currently used in standard light-water reactors. This thermal resilience is a cornerstone of the FMR’s safety.

Additionally, the reactor is designed to pair with an air-cooling system. The design also eliminates the need for a constant water source. As a result, the FMR becomes a viable solution for remote locations where traditional nuclear plants would be nearly impossible to build.

“The ARC-20 program has supported critical advances in the Gas-cooled Fast Reactor concept and demonstration of robust materials that enable an added layer of safety, while still enabling operation without the need for a water source,” said Dr. Christina Back, Vice President of General Atomics. “These features facilitate siting and compatibility for small communities and diverse applications, including the recycling of used nuclear fuel.”

The Path to 2030

As the technology “matures,” future efforts will focus on safety testing and refining the power conversion components. If these phases are successful, the industry could see a full-scale demonstration of the FMR in the 2030s.