The plastic bottle you tossed in the recycling bin today might actually help hold up your house tomorrow.

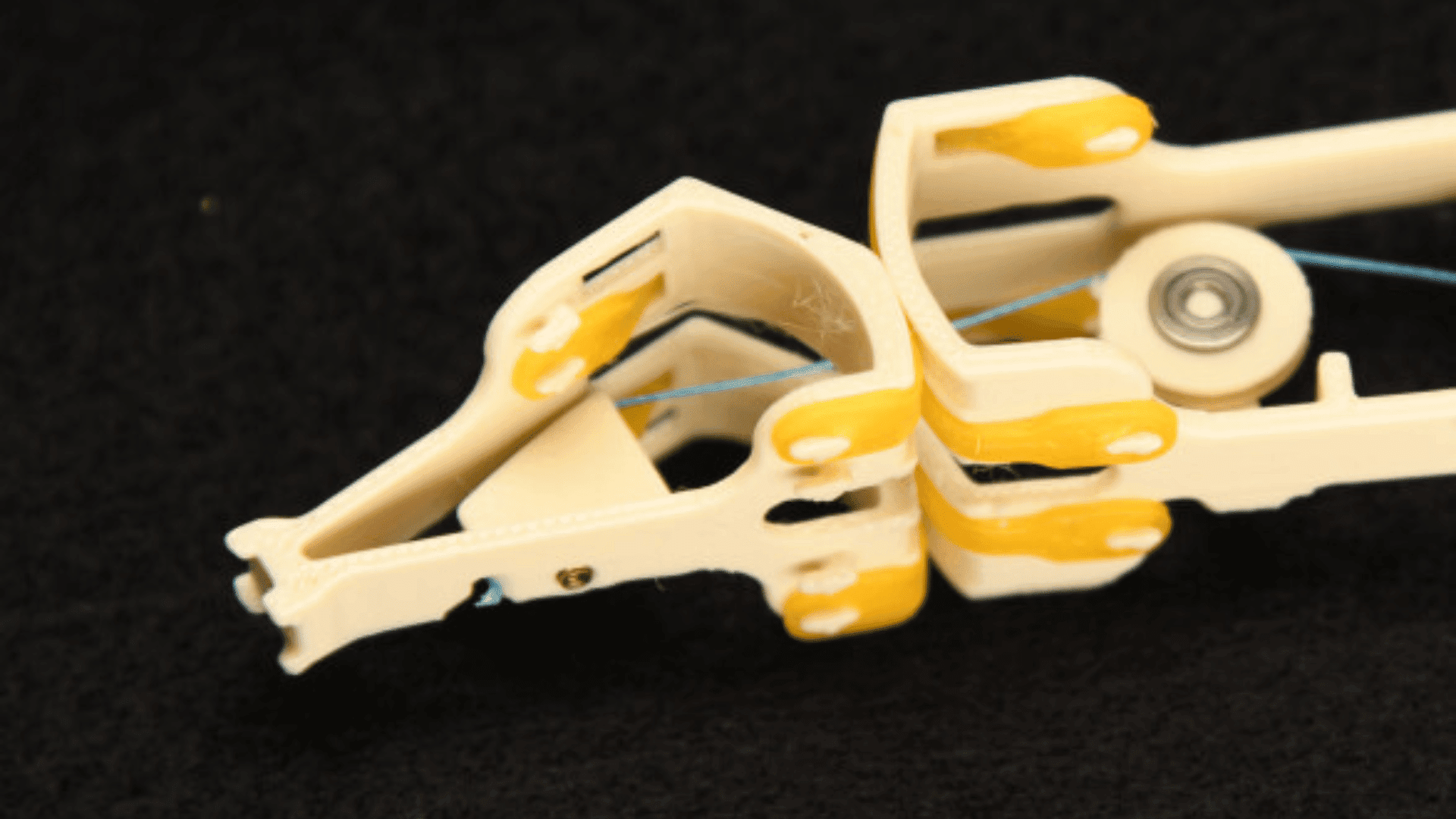

Engineers at MIT have found a way to take recycled plastic and turn it into 3D-printed floor trusses, the structural beams that keep your floors from sagging. When the team tested a floor frame made from these plastic parts, it held over 4,000 pounds. According to the engineers, these results beat the standards set by U.S. building officials.

Plastic Beats Wood

Building houses usually takes a lot of timber. But as the world grows, we’re running out of trees to keep up with the demand for new homes.

“We’ve estimated that the world needs about 1 billion new homes by 2050. If we try to make that many homes using wood, we would need to clear-cut the equivalent of the Amazon rainforest three times over,” said AJ Perez, a researcher at the MIT Office of Innovation. “The key here is: We recycle dirty plastic into building products for homes that are lighter, more durable, and sustainable.”

Right now, a typical wood truss is heavy and held together with metal plates. MIT’s plastic versions weigh only 13 pounds and can be printed in about 13 minutes. Because they are so light, you wouldn’t need a massive semi-truck to move them. For example, the researchers say a regular pickup truck or even a moped could get them to a construction site.

Printing With “Dirty” Plastic

Most recycling programs require plastic to be perfectly clean and sorted, which is expensive and slow. The MIT team, known as MIT HAUS, wants to skip those steps. They are working on a system where old water bottles and food containers go straight into a shredder and then into a giant 3D printer.

“We are starting to crack the code on the ability to process and print really dirty plastic,” Perez said. “The questions we’ve been asking are, what is the dirty, unwanted plastic good for, and how do we use the dirty plastic as-is?”

The goal is to set up small “micro-factories” in shipping containers near places where plastic waste piles up, like football stadiums. From there, they could print entire home frames, including walls, stairs, and roofs, right where people need them most.