Progress rarely looks like a straight line. Denise Johnson’s career journey from test engineer to leading resource industries at Caterpillar shows how curiosity, experimentation, and resilience can turn early uncertainty into lasting impact. Her story offers a practical roadmap for innovation in heavy industry—one built on learning, iteration, and long-term thinking.

Curiosity as a Career Compass

Johnson’s path began with shadowing engineers simply to understand what a vague job title really meant. That curiosity led her into hands-on testing labs, where she examined how steering systems fail and why durability matters in real-world conditions. The experience shaped a foundational mindset: analyze problems deeply, identify root causes, and treat every obstacle as data for the next iteration.

Those early lessons also bridged the gap between engineering fundamentals and leadership. Johnson’s career demonstrates that technical rigor and human-centered communication are not opposing forces—they are complementary skills in high-stakes industrial environments.

Observation Built the Caterpillar Brand

The conversation then zooms out to Caterpillar’s origins, where founders CL Best and Benjamin Holt moved beyond livestock-powered machinery by paying close attention to real-world challenges. Their observational insight led to early engines, track-type tractors, and a brand identity rooted in solving practical problems.

That origin story mirrors the modern product discovery process. Watch the system, name the friction, and design solutions that remove it. From its earliest days, Caterpillar’s progress came from understanding how work actually happens, not from assumptions made in isolation.

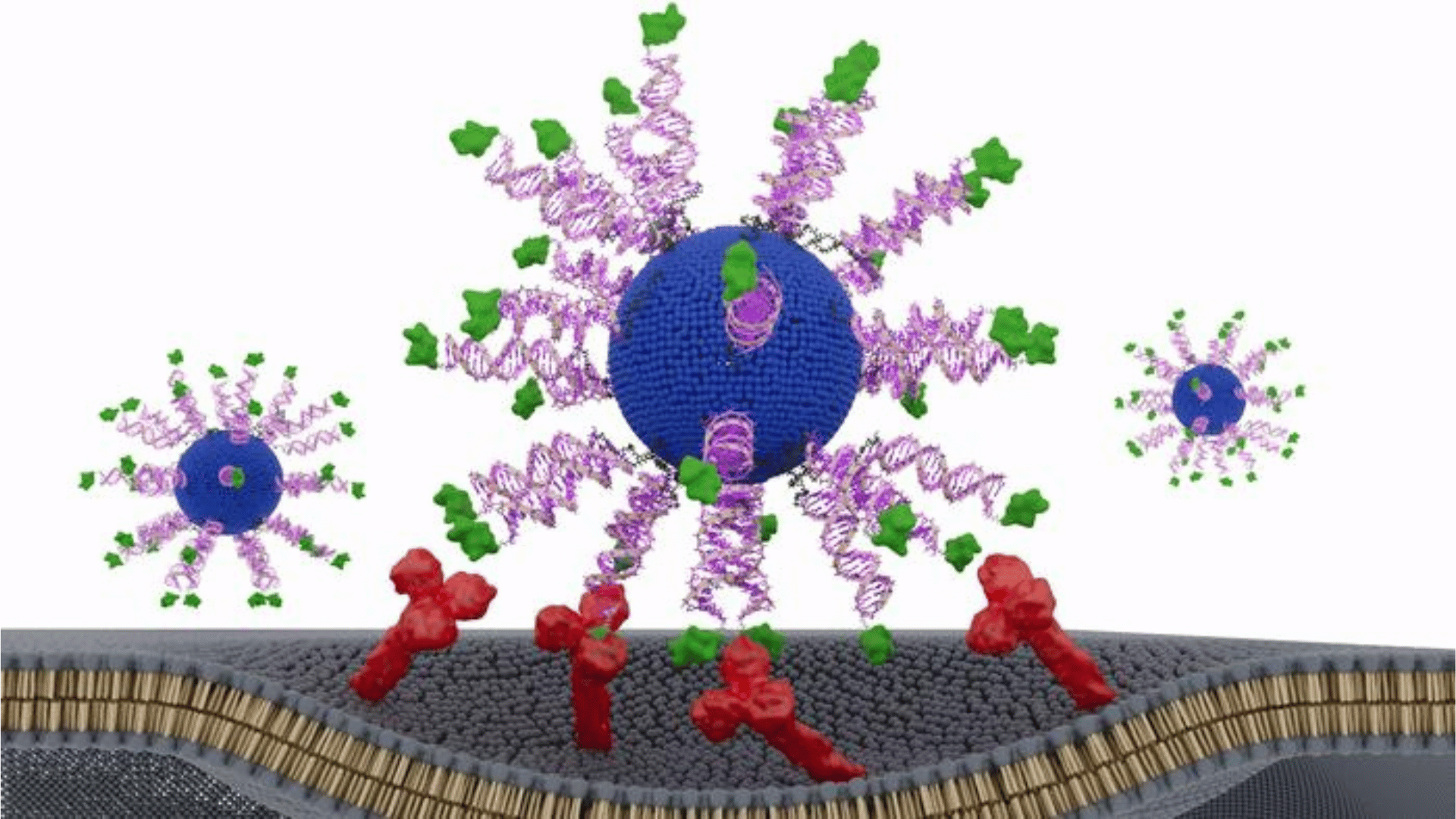

Designing Technology That Teaches

That same philosophy drives Caterpillar’s modern digital thread strategy. By embedding assistive technology into equipment, the company enables new operators to perform complex tasks, such as digging precise holes, without requiring months of training. At the same time, experienced crews benefit from synchronized workflows and fewer costly errors.

The goal isn’t technology for technology’s sake. It’s safer jobsites, faster learning curves, and machines that translate complex operations into predictable, repeatable outcomes across construction and mining environments.

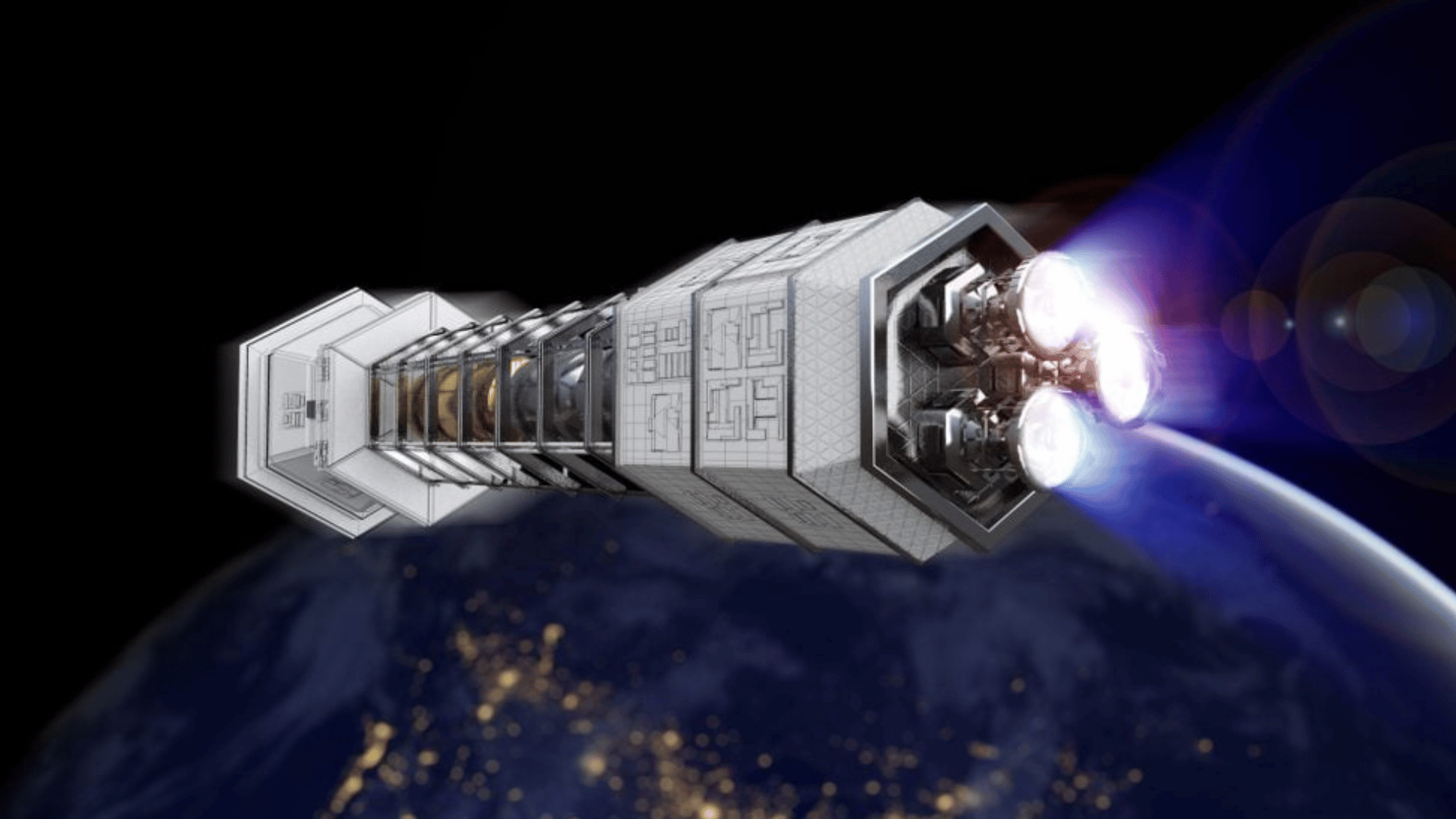

Autonomy at Industrial Scale

Autonomy takes those gains even further. Johnson describes fleets of five-story mining trucks operating without drivers, coordinated like a factory on wheels. Optimized routing boosts throughput, sensors monitor conditions with machine-level precision, and removing humans from cabs significantly reduces exposure to hazards.

This capability didn’t emerge overnight. Caterpillar began investing in autonomous systems in the mid-1980s, iterating across hardware, software, and systems integration for decades. Only through disciplined testing and long-term commitment did the technology become commercially reliable. The takeaway for innovators is clear: durable breakthroughs often require patience, persistence, and a willingness to rethink assumptions as data evolves.

Why Diverse Teams Build Better Machines

Behind every machine is a diverse team. Caterpillar employs more than 10,000 engineers and nearly 1,000 PhDs, alongside technicians, communications specialists, finance leaders, and marketers. Johnson frames success not as climbing titles, but as making a meaningful difference.

That mindset drives hiring for diversity of background and thought, while supporting careers that can flex across design, manufacturing, and leadership roles. Hard skills provide technical depth, but soft skills—clarity, teamwork, reliability—create momentum. Complex products are built by cross-functional teams that know how to work together.

Resilience as an Innovation Strategy

The episode closes with a focus on resilience. Projects stall. Offers fall through. Prototypes fail. Progress comes from decoupling identity from outcomes, treating results as information, and learning how to “fail forward.” Sometimes, Johnson notes, stepping back is the fastest way to move ahead.

For professionals looking toward the future of work in heavy industry, the opportunity is wide open. AI-enabled equipment, robotics, electrification, and data-driven operations all need builders across disciplines. From fields once plowed by horsepower to mines managed by autonomous fleets, progress continues when we listen closely to problems, invest for the long term, and commit to making work safer, smarter, and more connected to opportunity.

This blog post was generated using Buzzsprout’s CoHost AI tool and is based directly on content from the associated podcast interview. This article has been reviewed and edited by Tomorrow’s World Today staff.