The vast, intricate process of bringing goods to life—from the paper we write on to the packaging that keeps our food fresh—often involves powerful, complex, and sometimes dangerous steps. Imagine handling immense, heavy rolls of material, a task both physically punishing and highly prone to error.

Now, picture a future where precision robots step in as the gentle giants of the factory floor, lifting the massive burden and freeing human workers for safer, more creative endeavors.

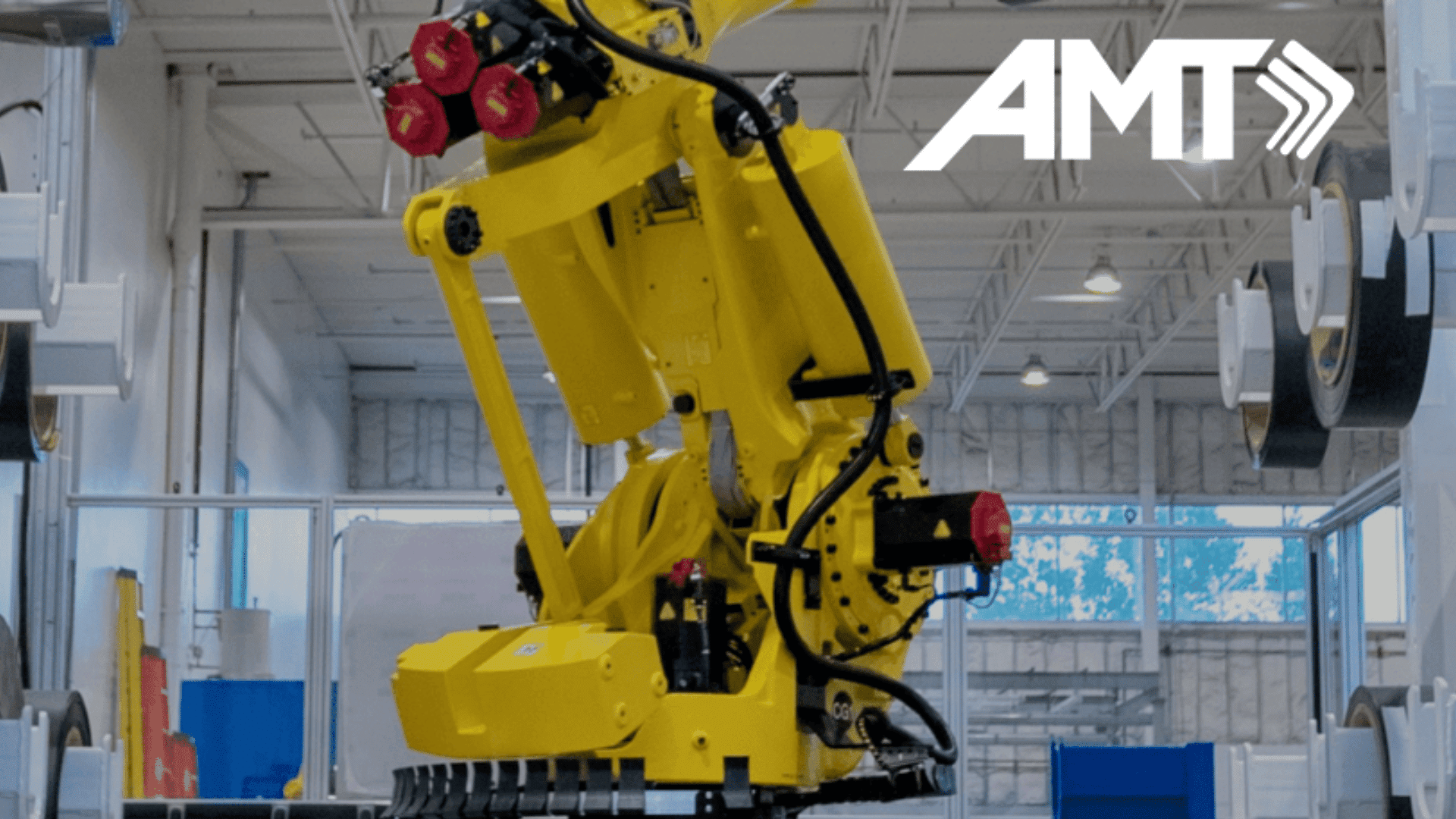

Applied Manufacturing Technologies (AMT) has launched new robotic solutions that are quietly yet profoundly reshaping the “converting industry,” or the sophisticated process of turning raw materials into finished goods like packaging, by making the movement of these heavy rolls safer and more efficient than ever before.

The Big Idea

This innovation is more than faster machines; it’s about elevating the standard of living for the people who make our world run. The core concept involves deploying advanced robotic arms, similar to those often used for car assembly, to manage the movement of heavy, large coils and rolls of materials, such as paper, plastic, or film, within a manufacturing facility. Think of it as giving the factory floor a team of tireless, perfectly coordinated athletes who specialize in safely moving objects that weigh as much as a small car.

The novelty lies in applying advanced, flexible robotics and integrated vision technology to the hazardous, repetitive, and often manual tasks of roll handling in packaging and converting operations.

Life Before

Before this wave of automation, the process of moving massive rolls of material—which can weigh thousands of pounds—was a significant operational challenge. It was often accomplished manually or with older, less flexible mechanical equipment. These methods were inefficient, slow, and, most importantly, presented a continuous risk of physical strain and serious injury to human operators. Roll handling has long been considered one of the “most physically demanding and risk-prone tasks in manufacturing”.

The need for this type of system grew out of decades of industrial experience. Applied Manufacturing Technologies (AMT), founded in 1989, has been a leader in automation engineering, specializing in material handling systems.

Their focus, honed by years of work in complex areas like palletizing and integrating Autonomous Mobile Robots (AMRs), has now been applied to this overlooked area of converting operations. The challenge was clear: manual handling was creating a persistent bottleneck and unnecessary risk, demanding a robust, adaptable, and safety-driven solution.

The Robotic Breakthrough

The new robotic roll handling system is not a single tool but an entire integrated solution, acting as a conductor for the symphony of manufacturing. The key mechanism is its blend of adaptability, advanced sensing, and seamless integration.

Firstly, the systems are designed for high flexibility, supporting a wide variety of roll sizes, material types, and pallet configurations. This means one system can handle multiple products, making it a valuable long-term investment. Secondly, they feature automatic tool-changers, allowing the robot to swap out end-of-arm tooling as needed without human intervention, maintaining production flow.

The systems are also designed to integrate flawlessly with the next generation of factory equipment, including conveyors and Autonomous Mobile Robots (AMRs), enabling true digital twin simulation and efficiency.

“Roll handling is one of the most physically demanding and risk-prone tasks in manufacturing,” said Craig Salvalaggio, President at AMT. “We’ve engineered systems that reduce that burden, improve throughput, and allow customers to redeploy labor where it matters most. It’s a practical solution to a persistent problem.”