Localized renewable energy demand is rising, but it often comes to a halt where wind speeds are low. However, researchers at the Fraunhofer Institute for Applied Polymer Research (IAP) are seeking a solution. Through a partnership with the BBF Group, researchers have developed a lightweight rotor for small wind turbines. These turbines are specifically designed for regions with light breeze conditions.

Their goal is to provide a decentralized and efficient energy supply for households, businesses, and disaster relief.

Small Turbine, High Efficiency

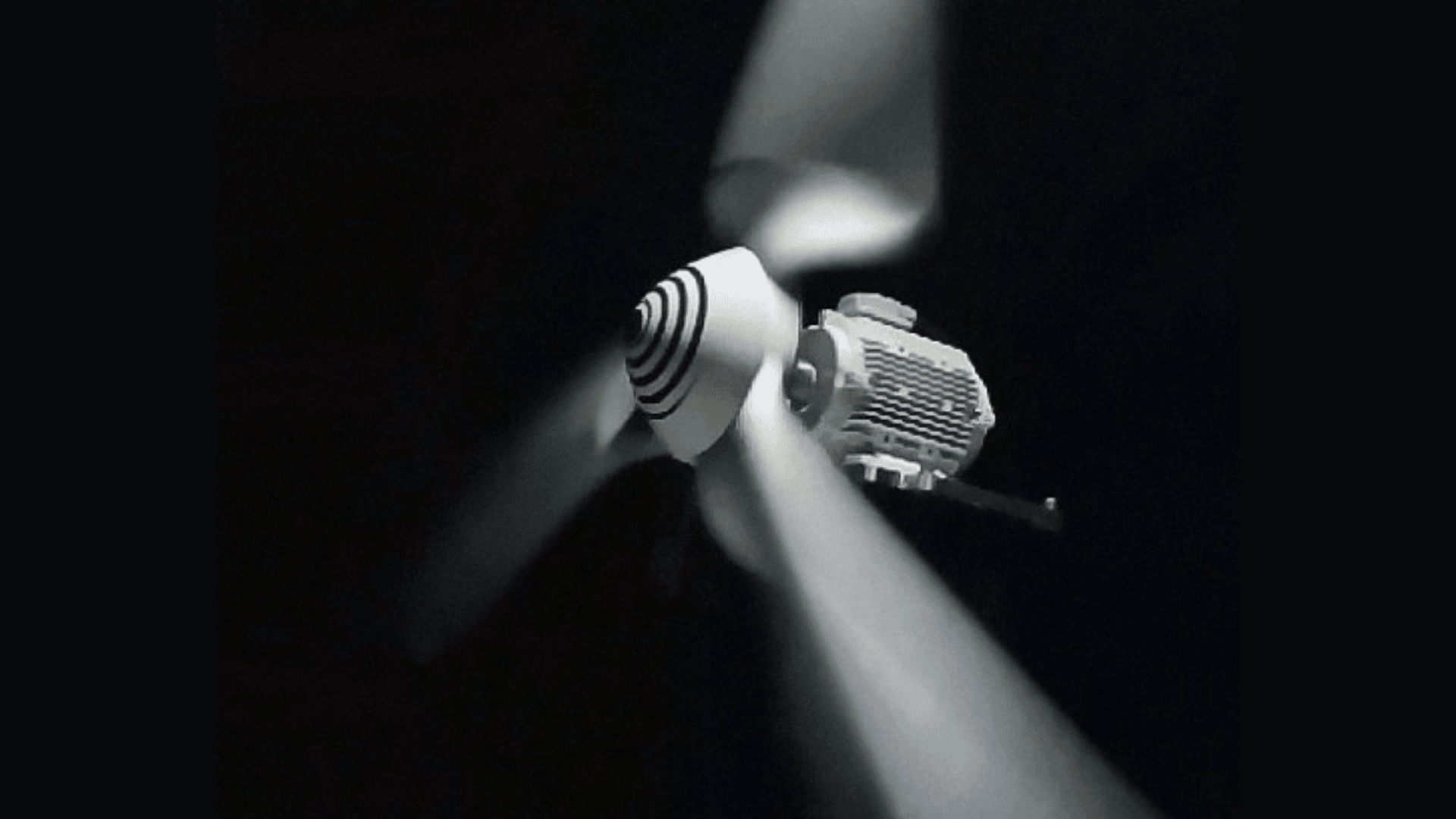

A drastically reduced starting speed is the core of this innovation. According to wind tunnel tests, rotors begin turning at 2.7 meters per second, which is significantly lower than the roughly 4 meters per second required by comparable systems. “Our goal is to use the power of the wind as effectively as possible to generate electrical energy,” said Marcello Ambrosio, Head of Simulation and Design at Fraunhofer IAP’s PYCO division.

Researchers reportedly achieved remarkable results by optimizing the aerodynamic design and manufacturing process.

These mini turbines reach a speed of up to 450 revolutions per minute and deliver 2500 watts at 10 meters per second. According to engineers, this makes it roughly 83% more powerful than similar systems. In addition, its measured efficiency of 53% is close to the physical maximum of 59%.

“Efficient small wind turbines make an important contribution to an independent energy supply,” said Raúl Comesaña M., Managing Director of the BBF Group.

Automated and Safe

The rotor’s lightweight construction uses hollow, two-shell fiber composite materials. As a result, the overall weight is reduced by up to 35% compared to conventional designs. Furthermore, the manufacturing process utilizes high-tech automation. Ambrosio and his team utilized an industrial 3D printer for mold design and an Automated Fiber Placement system for the precise fabrication of components.

In addition, the design has a special laminate structure for safety. Ambrosio explained, “We designed the individual layers of the composite material so that the rotor blades can flex elastically in a storm and turn out of the wind.” The design reduces the rotation speed and protects the turbine from overload without complex control tech.

Five prototypes are currently undergoing field testing to investigate the impact of location and height on performance. Future work includes developing lightweight structures from chemically identical materials, known as monomaterials, to enhance recyclability and environmental sustainability.