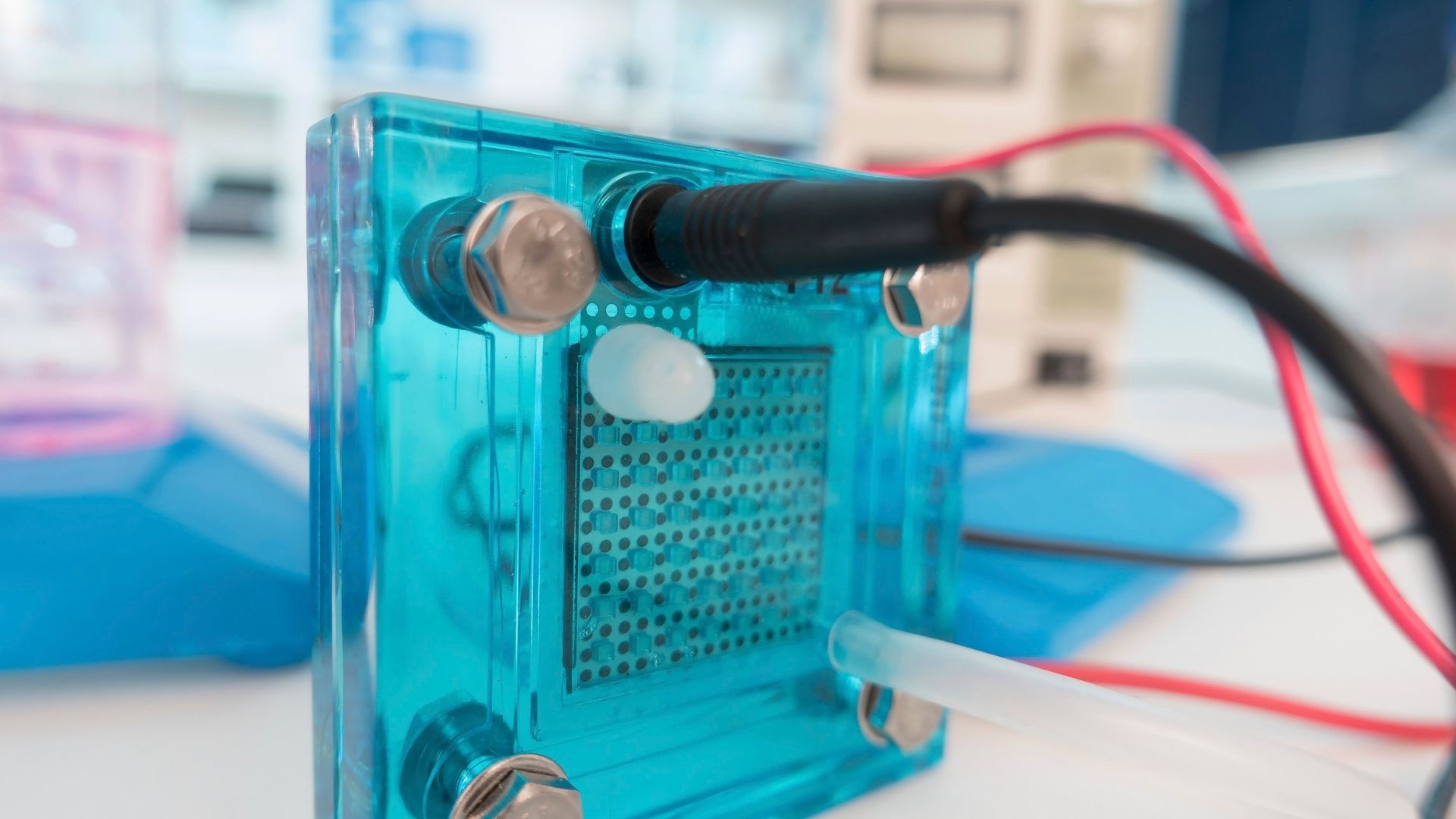

Inspired by the structure of coral, researchers from the Technical University of Denmark designed powerful and lightweight fuel cells using 3D printing.

Coral-Inspired Fuel Cells

Fuel cells are used in various industries such as data centers, hospitals, ships, and hydrogen cars. They’re highly valuable for renewable energy systems due to their ability to generate and store energy through electrolysis.

The new design, called the Monolithic Gyroidal Solid Oxide Cell (or The Monolith), is “fully ceramic”. This eliminates the heavy metal components that make up 75% of a typical fuel cell’s weight.

It’s engineered to have the largest surface area possible while remaining lightweight, which allows gases to flow freely, improves heat distribution, and increases mechanical stability. The design is capable of producing over one watt per gram.

“Currently, using electricity-based energy conversion, such as batteries and fuel cells, doesn’t make sense for aerospace applications,” said Venkata Karthik Nadimpalli, a senior researcher and corresponding author.

“But our new fuel cell design changes that. It’s the first to demonstrate the Watts to gram ratio – or specific power – needed for aerospace, while using a sustainable, green technology,” explained the author.

The fuel cell showed its durability by withstanding temperature swings of 100°C. It also showed no structural failures when repeatedly switched between power-generating and power-storing modes. When used in electrolysis mode, they can produce “hydrogen at a rate nearly ten times” faster than standard models.

Another benefit of the new design is that it could simplify manufacturing processes. Whereas conventional solid oxide cell stacks require dozens of steps and multiple materials, the new system can be created in five steps and has proven to be more durable over time.

Researchers behind the project see its potential to benefit the aerospace industry by reducing the cost and environmental impact of commercial jets and space missions.

“Still, I believe that we can improve the system further using thinner electrolytes, cheaper current collectors, like silver or nickel instead of platinum, and even more compact designs,” stated Nadimpalli.

The findings were published in the journal Nature Energy.