According to the U.S. Department of Agriculture, 30-40% of the nation’s food supply goes to waste annually. That is a staggering number. Billions of pounds of food rot in landfills, releasing greenhouse gases. Similarly, plastic waste poses a concerning threat.

However, researchers are working on a way to repurpose a significant amount of food waste into biodegradable plastics, simultaneously tackling two environmental issues.

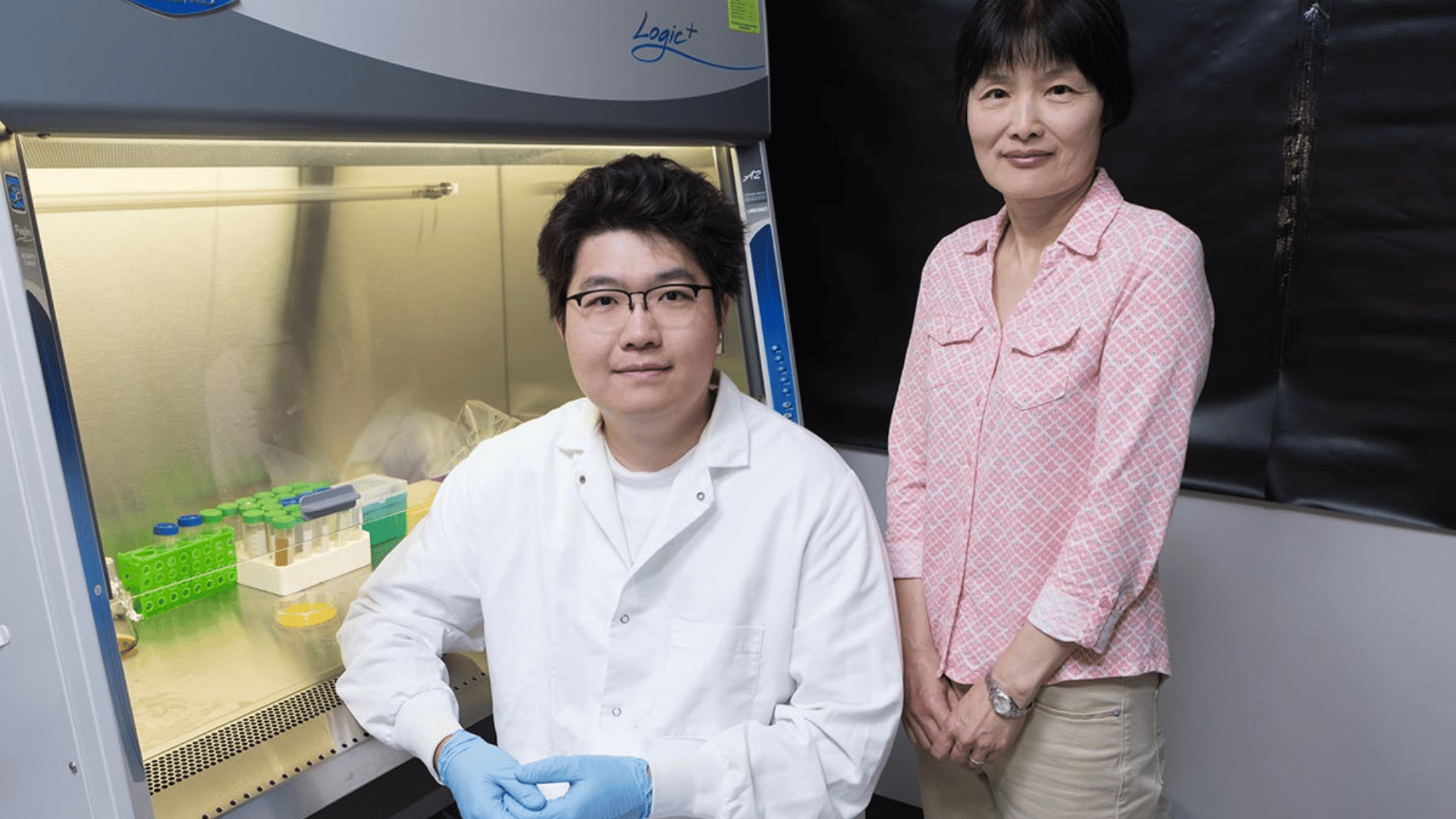

A team from Binghamton University in New York is pioneering this innovation. The team is led by a PhD candidate, Tianzheng Liu. With faculty support from Professor Sha Jin and Professor Kaiming Ye, the team published their foundational findings in Bioresource Technology. Their work shows how companies could scale up the innovative process.

Food Waste to Eco-Friendly Plastic

The research originates from a state grant that Jin received to explore food waste solutions. “We can utilize food waste as a resource to convert into so many industrial products, and biodegradable polymer is just one of them,” she explained. “We’re aiming not only to valorize food waste but also reduce manufacturing cost of this eco-friendly polymer.”

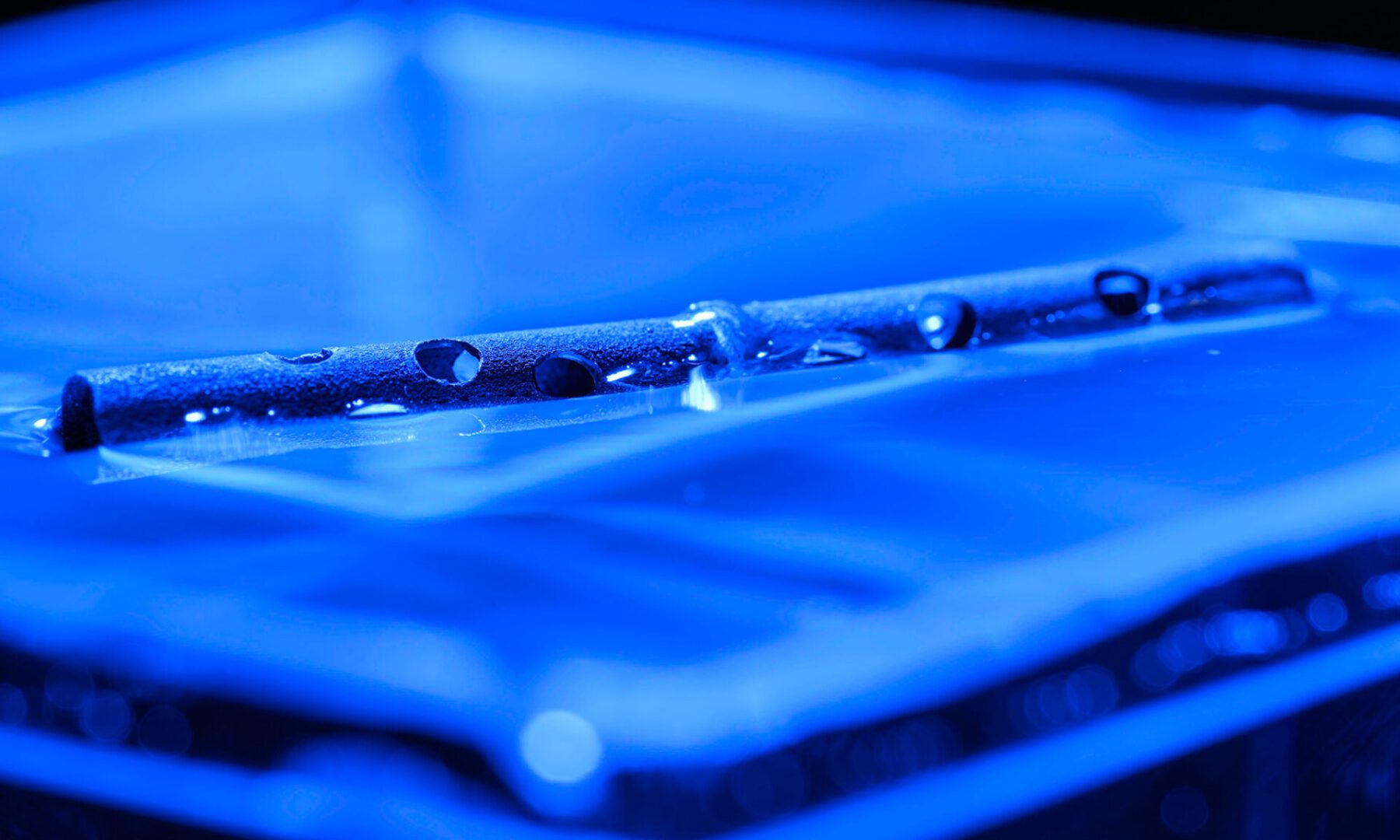

Biodegradable plastic production is traditionally costly and relies on refined sugars. However, Binghamton’s team uses Cupriavidus necator bacteria. They feed the bacteria lactic acid, which is fermented from food waste and serves as a carbon source. Ammonium sulfate is used as a nitrogen source.

Bacteria synthesize polyhydroxyalkanoate (PHA) plastic as a natural way to store carbon and energy. About 90% of the PHA is harvestable for biodegradable products.

Liu says the research was not without challenges and hurdles. “The bioconversion of food waste into organic acids was a relatively easy one.”The bioconversion of food waste into organic acids was a relatively easy one,” he said. “Cultivation of the plastic-producing bacteria was hard, because at the beginning I didn’t have experience with bacteria fermentation for producing biopolymer.”

He added, “At every move, I felt like something was not what I expected.”

Researchers answered critical questions about the process’s viability in an industrial setting. According to the press release, they can store food waste for up to a week without negatively impacting the bioconversion, which offers flexibility. In addition, they determined that the process is “very robust,” regardless of specific food types, as long as different wastes are mixed consistently.

The team’s next step is scaling up the process. They seek grant funding or industrial partnerships to continue the process at a larger level.