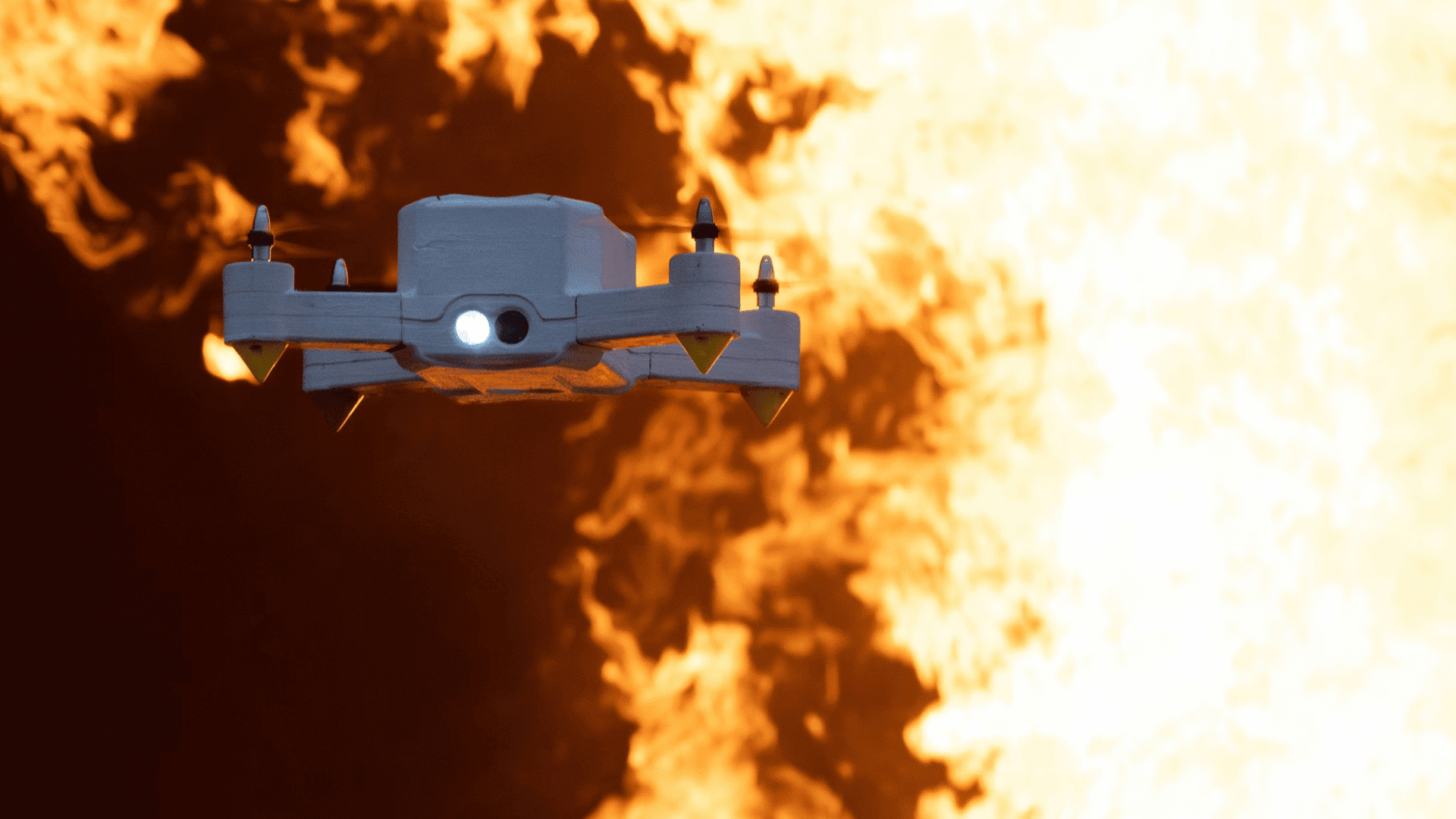

The UK’s first major infrastructure project, committed to carbon-neutral construction, used the world’s first hydrogen-powered digger.

Hydrogen-Powered Digger

A project that will connect Kent and Essex via a new road and tunnel, the Lower Thames Crossing aims to reduce its construction carbon footprint by 70%. To achieve this, the project will utilize low-carbon materials, such as steel and concrete, and employ sustainable and innovative construction methods.

The goal of this project is to double road capacity across the Thames, alleviate traffic at the Dartford Crossing, and provide a direct freight route linking the South East ports, the Midlands, and the North.

The Lower Thames Crossing project marked a milestone with the live deployment of a British-made JCB hydrogen-powered backhoe loader for survey work. Operated by Skanska and supplied by Flannery Plant Hire, National Highways stated that the machine is powered by hydrogen from Ryze.

Powered by a hydrogen-fuelled internal combustion engine, this marks the first instance such machinery was used outside of a test environment. The digger reportedly reduced CO2 emissions by more than 1.1 tons in its first month of operation.

“This project will prove that the British construction industry has the vision and skills to build the projects needed to drive growth in a way that enhances, not impacts, the local environment,” mentioned Matt Palmer, executive director for the Lower Thames Crossing.

JCB managing director Steve Fox stated that it is the first time hydrogen has been proven as a carbon-neutral fuel in a working construction machine on a major UK project.

Roads and Buses Minister Simon Lightwood highlighted the wider impact of the project, stating that it will, “be completely carbon neutral, showing major infrastructure projects can be delivered hand in hand with our ambitious environmental targets.”

Construction on the Lower Thames Crossing is expected to begin in 2026, and the new route is expected to open in the early 2030s.