Rare earth elements (REEs) are a crucial component for almost all modern technology, everything from smartphones to electric vehicle batteries. However, retrieving the elements involves a complex mining process.

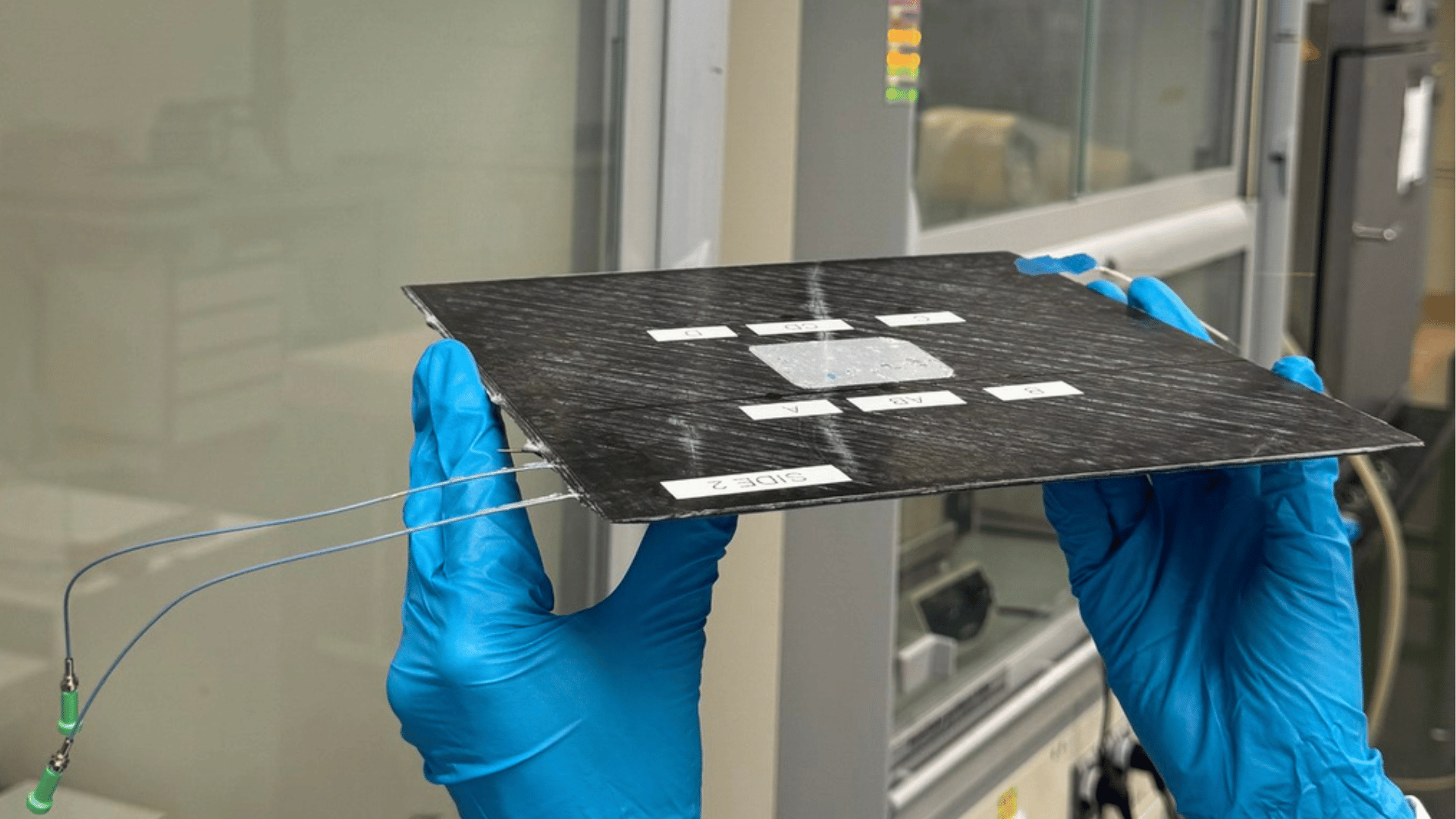

In a groundbreaking study, researchers at Rice University have revealed an efficient and environmentally friendly method for extracting rare earth elements from end-of-life magnets. The process combines Flash Joule Heating (FJH) technology with chlorination. Researchers believe the method could revolutionize the recycling of critical metals.

Researchers published their findings in the Proceedings of the National Academy of Sciences. Rice University professor James Tour and his colleagues led the study.

A Shift in Rare Earth Element Processing

Metallium Ltd. exclusively licenses the new application. The company plans to integrate the process into its commercialization efforts.

Advertisement

“Rice University’s breakthrough confirms what we see as the future of critical metals processing: cleaner, faster and vastly more efficient than current processes,” said Michael Walshe, Managing Director and CEO of Metallium. “The ability to recover rare earths from magnet waste at scale, with higher yields, lower costs, and zero acid or wastewater, represents a paradigm shift for global supply chains.”

Current rare earth element recovery methods involve harsh chemicals, generate wastewater, and are energy-intensive. However, the new method reportedly can overcome these issues. According to researchers, it provides a domestic, sustainable, and high-yielding source of the essential elements.

Lab Success to Industry Application

Metallium is moving quickly to commercialize the findings. Walshe said, “Metallium is uniquely positioned, with exclusive rights to this technology, to take it from laboratory success into industrial reality.”

Their next step is adapting Rice University’s process at Metallium’s pilot plant in Texas. Walshe explained, “With our exclusive rights to commercialize Flash Joule Heating for critical metal recovery, we intend to adapt these Rice University findings to our pilot-scale prototype system in Texas.”

Metallium has a central strategy of developing a low-carbon and highly efficient approach to critical metal recovery. The FJH technology is currently patented to extract critical materials, including gallium, germanium, antimony, REEs, and gold. It extracts these materials from various feedstocks, including e-waste, refinery scrap, and monazite.