A new, printable aluminum alloy developed by MIT researchers is five times stronger than traditionally manufactured aluminum. Additionally, researchers say, it can withstand temperatures of up to 400 degrees Celsius (752°F). A significant breakthrough in materials science is expected to revolutionize industries such as aerospace and automotive.

According to researchers, the resulting metal offers a lighter, cheaper, and more temperature-resistant alternative to conventional materials such as titanium. Mohadeseh Taheri-Mousavi (who conducted the work as a postdoc at MIT) and John Hart, the head of the Department of Mechanical Engineering at MIT, led the research team.

They credited a novel approach combining simulations with machine learning for their success.

A Breakthrough In Durable, Printable Alloys

The team says their cutting-edge machine learning methodology trimmed the vast number of possible material compositions to search through. Traditionally, methods require simulating over one million combinations. However, the team’s approach identified the ideal mix after evaluating only 40 possible compositions.

Researchers explained that the alloy’s microstructure is the secret to its enhanced performance. Specifically, they say, the densely packed microscopic constituents called “precipitates” are the key. They achieved this high-strength structure by using a form of 3D printing called Laser Bed Powder Fusion (LBPF). LBPF replaced the traditional metal casting method.

“Here, 3D printing opens a new door because of the unique characteristics of the process—particularly, the fast cooling rate,” Hart explained. “Very rapid freezing of the alloy after it’s melted by the laser creates this special set of properties.”

This rapid cooling created the small-precipitate, high-strength alloy that their machine learning model predicted.

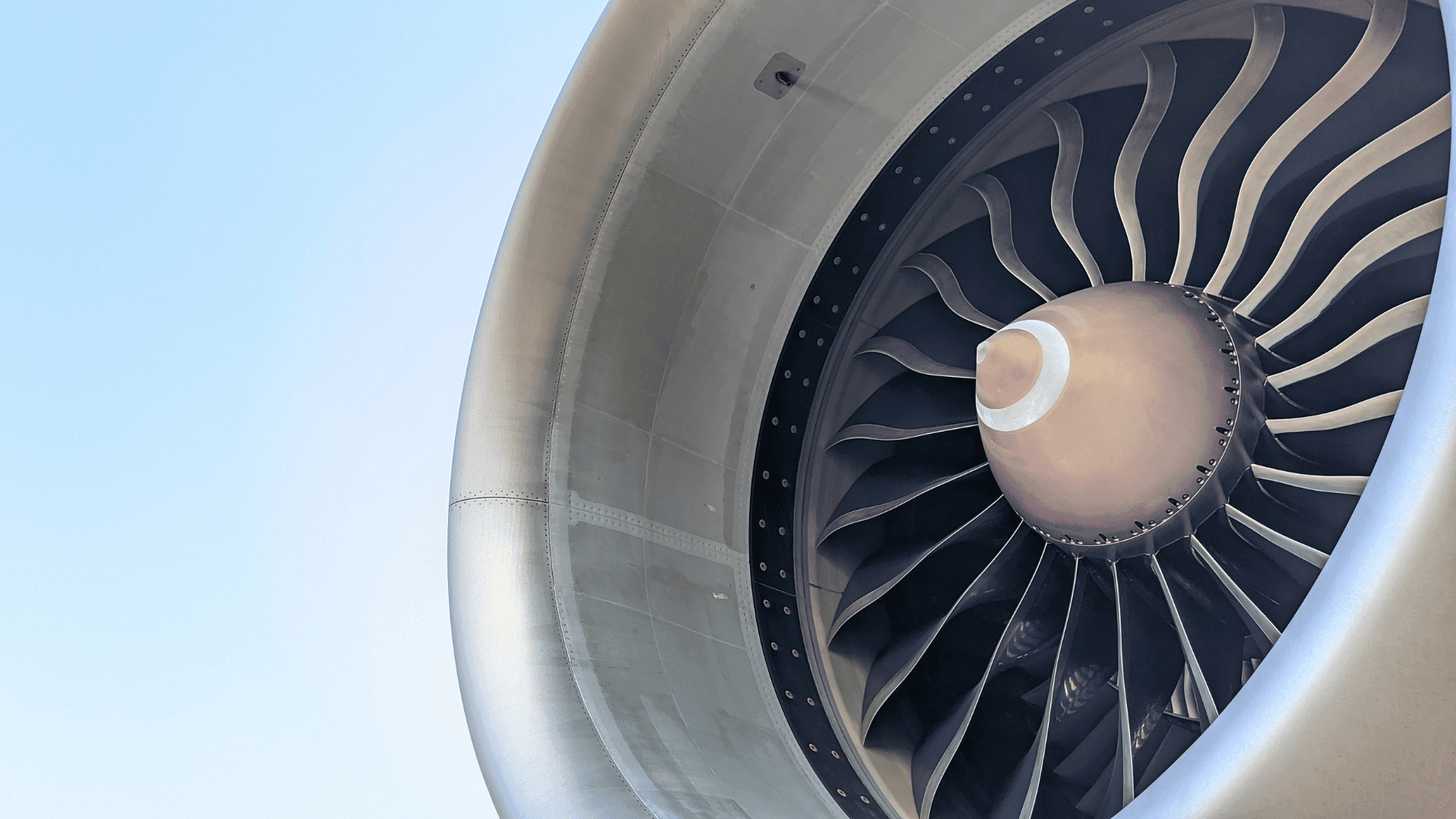

Researchers are excited about the potential applications of this strong, lightweight, and temperature-resistant material. They envision the alloy being used for fan blades in jet engines because current materials are made from heavy and costly titanium.

“If we can use lighter, high-strength material, this would save a considerable amount of energy for the transportation industry.” Mohadeseh Taheri-Mousavi said.

Hart added to the list of potential uses. He said, “Because 3D printing can produce complex geometries, save material, and enable unique designs, we see this printable alloy as something that could also be used in advanced vacuum pumps, high-end automobiles, and cooling devices for data centers.”