When you think of medical adhesives, your mind probably doesn’t wander to slugs. But that’s exactly where the next frontier in medicine may lie. In our upcoming podcast episode, we sit down with Benjamin Freedman, PhD, and Phoebe Kwon of Limax Biosciences, whose lab is reimagining wound care and surgical repair by drawing insights from a humble garden slug.

Garden Slugs to Operating Rooms

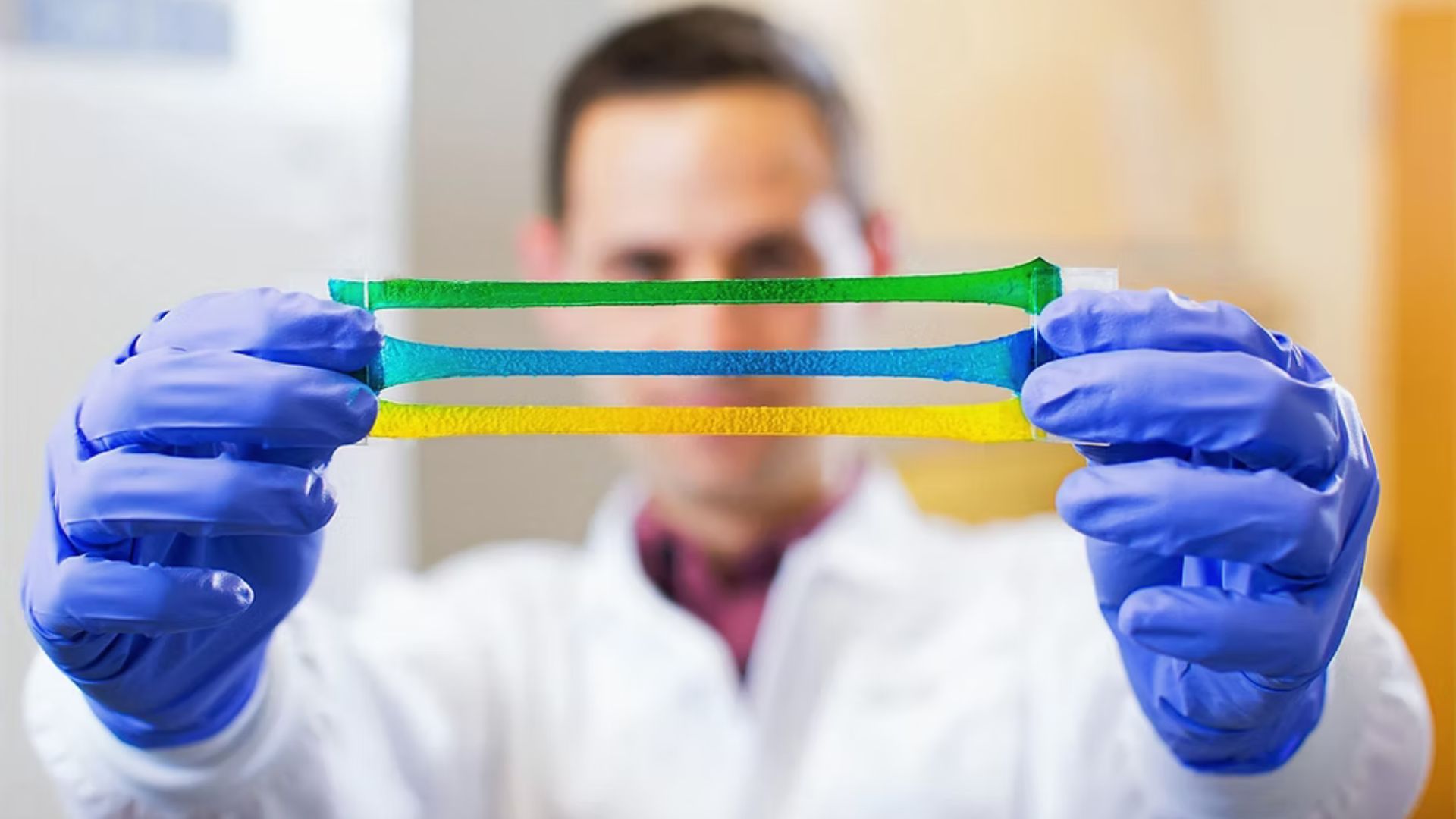

Most biomed researchers try to mimic muscles or tissues when designing adhesives for wet environments. The problem? These adhesives stick well to surfaces, but the adhesive bodies themselves break and tear under stress. That’s where slug slime offers a secret. The mucus of Dusky Arion slugs is about 90% water, yet it can stretch 10–15× its original length without tearing. That property—stretchiness + strength in a wet medium—is exactly what holds the key to a medical adhesive that works where others fail.

Engineering the Breakthrough

Friedman and Kwan didn’t use any real slug parts. Instead, they translated slug chemistry into a dual-network hydrogel design. One network grants flexibility, the other reinforces toughness. On top of that sits a liquid adhesive layer—rich in primary amines—that acts like slug slime, enabling strong binding to wet tissues while preserving the internal integrity of the hydrogel.

The moment of truth came when they tested it on a beating pig heart. A material that is nearly all water, yet firmly grips a moving organ, signals a leap beyond current surgical adhesives.

Advertisement

Why This Matters

-

Seals wounds in wet, dynamic environments—a huge challenge in internal surgery

-

Flexible and cuttable—you can shape it without fracturing

-

No cold storage needed, extended shelf life, sterility in demand

-

Holds high drug loads (up to 500 mg/mL) while staying adhesive—opening doors to localized, sustained drug delivery

Where It’s Headed

Since winning the Harvard President’s Innovation Challenge in 2022, Limax has pushed their adhesive through multiple optimization rounds. They’re contending with real-world constraints: sterilization, storage, handling, regulatory classification (Class II, III, and combo products), and clinical trial design. Their hope? To launch human feasibility studies after proving safety and function in surgical preclinical models.

Their vision spans neurosurgery, general surgery, dermatology, and more. They plan to remain lean, forging partnerships to scale production while their core team pushes the boundaries of innovation.

This blog post was generated using Buzzsprout’s CoHost AI tool and is based directly on content from the associated podcast interview. This article has been reviewed and edited by Tomorrow’s World Today staff.