Building a factory or designing a new product is expensive. If you get it wrong, fixing mistakes in the real world costs a lot of money and time. Siemens is trying to fix that with a new piece of software called Digital Twin Composer.

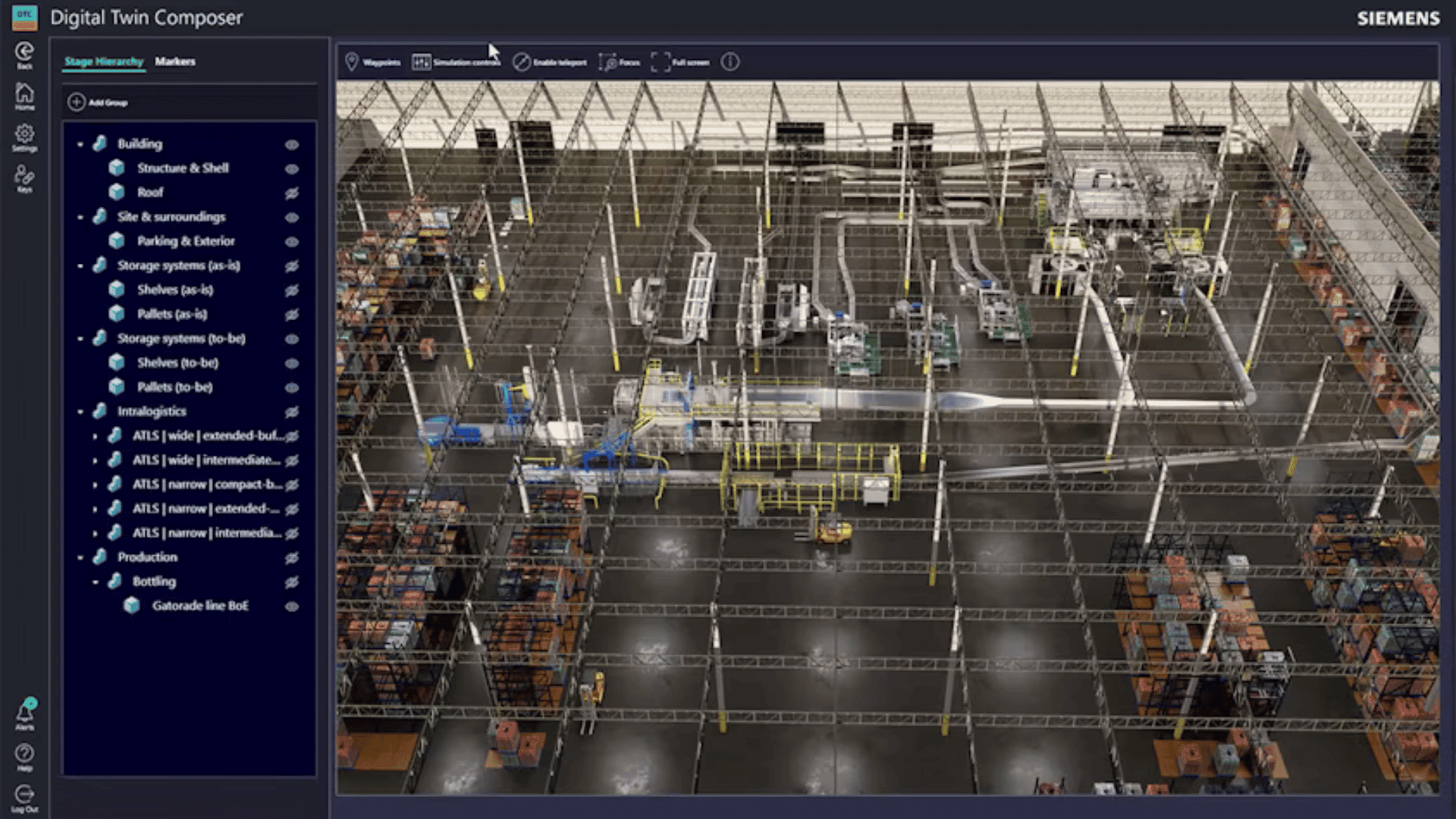

According to the company, this tool helps companies build what it calls “Industrial Metaverse” environments. While it sounds very “futuristic,” the idea is actually pretty practical. It allows businesses to combine 2D and 3D data with real-time information to create a photorealistic, working copy of a product or a factory.

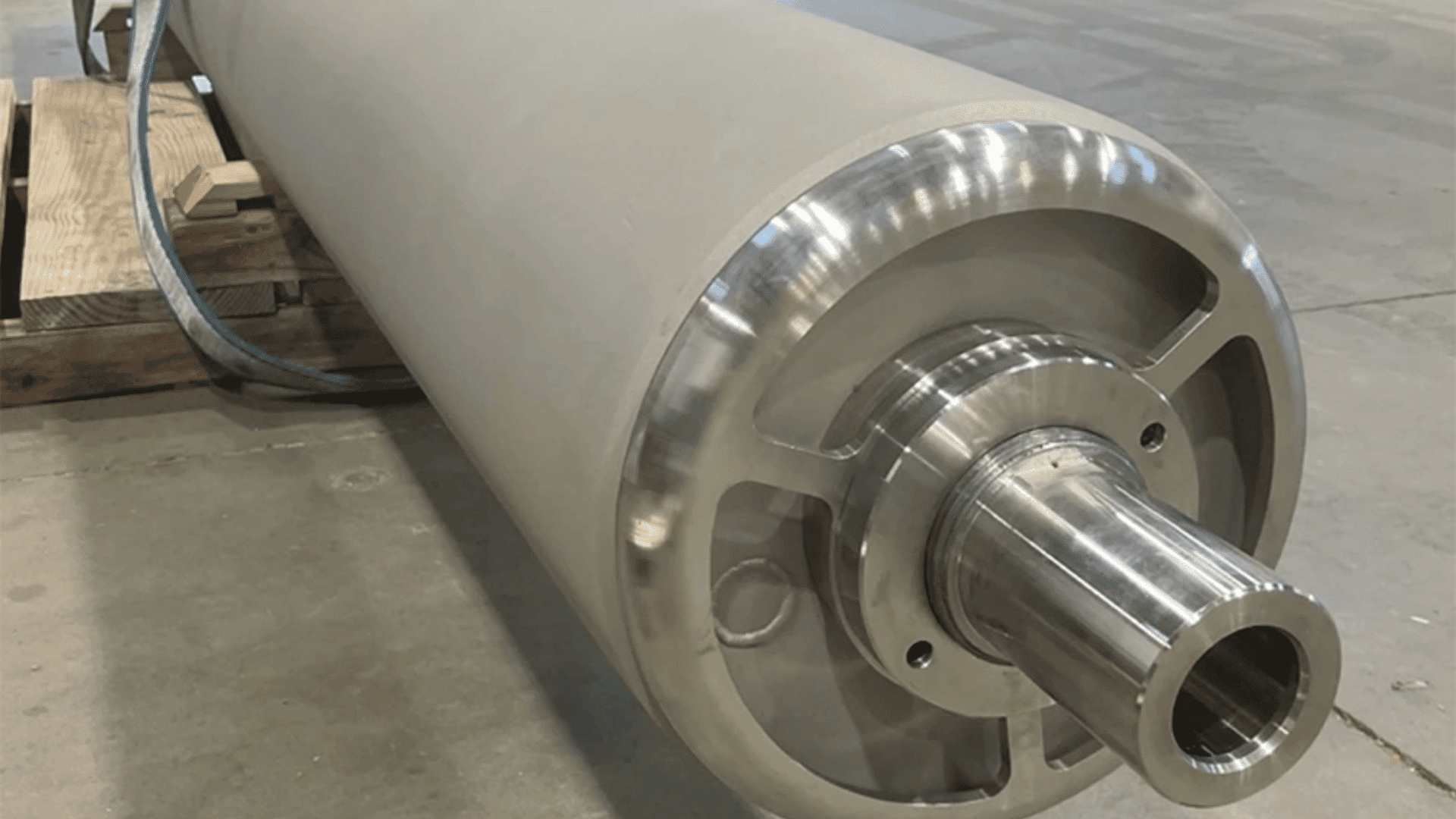

By using libraries from NVIDIA Omniverse, these digital models obey the laws of physics. This means engineers can see exactly how a new smartphone or a massive tanker ship will work before they actually build it.

Seeing the Digital Twins in Action

It’s easier to understand this if you look at a real example. Siemens teamed up with PepsiCo to digitally transform some of its U.S. manufacturing and warehouse sites. Instead of making a 3D drawing, they recreated every machine, conveyor belt, and pallet route with physics-level accuracy.

Once the digital twin was set up, PepsiCo used AI agents to simulate different scenarios. As a result, the system identified up to 90% of potential issues before any physical changes were made. This helped them get a 20 % increase in throughput immediately. It also led to a 10 to 15% reduction in capital expenditure because they could find hidden capacity in the virtual world instead of buying unnecessary equipment.

Breaking Down the Silos

A big issue in manufacturing is that design, engineering, and production teams often work separately using different tools. Digital Twin Composer tries to get everyone on the same page by putting design, simulation, and operations into one view.

“The new Digital Twin Composer delivers on our vision for the industrial metaverse. It helps manufacturers to overcome the unprecedented challenges of mastering complexity, accelerating production, reducing costs and increasing profitability,” said Joe Bohman, executive vice president, PLM Products, Siemens Digital Industries Software.

The software creates a “digital thread” that connects all these different stages. It allows teams to test automation and processes in minutes.

Rev Lebaredian, vice president of Omniverse and Simulation Technology at NVIDIA, explained why this matters: “By integrating NVIDIA Omniverse libraries into Digital Twin Composer, enterprises can take advantage of physically accurate simulation across their workflows to validate their entire lifecycle – from product design to factory logistics – in the virtual world before committing a single atom to the real one.”