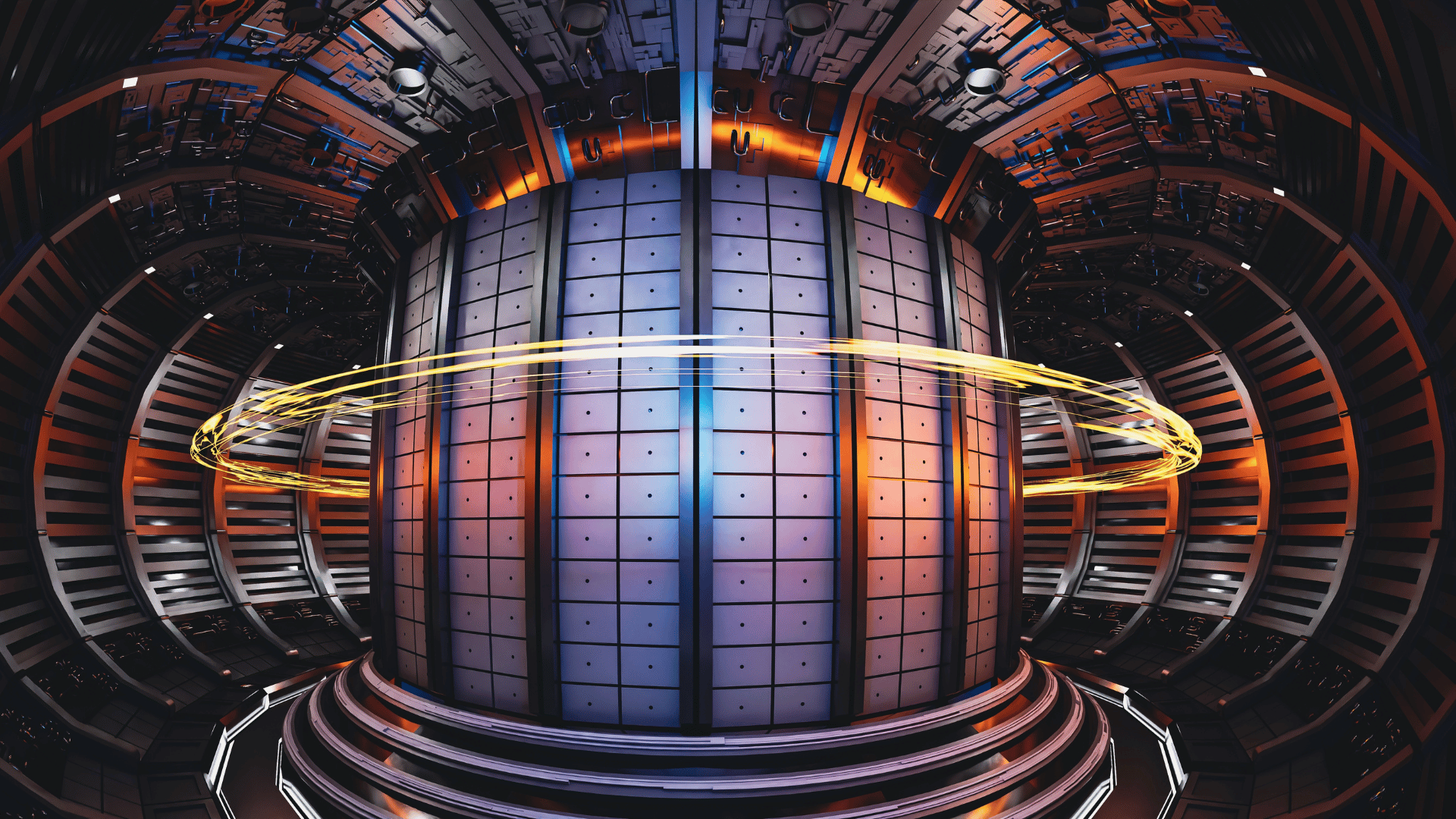

Nuclear fusion is the energy source that powers the Sun. Scientists and engineers continue their quest for the clean, nearly limitless energy source. However, finding metals that are durable enough to withstand the Sun’s temperatures remains a significant challenge. This is one of the roadblocks that stands in fusion’s path.

University of Miami engineers are studying advanced metal alloys at a scale hundreds of times smaller than a human hair that could withstand such extreme temperatures.

New Metal Alloy Revolutionizing Nuclear Fusion

Associate Professor of Mechanical Engineering Giacomo Po leads the team of engineers. Po and his team focused a beam of ions onto tiny metal samples, manipulating their form and observing how they behave when exposed to extreme conditions. The professor says their work contributes to “the holy grail, a dream that scientists have been chasing for decades.” In this case, the holy grail is nuclear fusion.

High-temperature, high-radiation environments inside future commercial fusion reactors require a new class of materials. Initial layers utilize refractory metals, such as tungsten, while the deep core requires more robust materials.

This led Po to study high-entropy alloys (HEAs), which are created by mixing five or more elements in relatively equal proportions. According to Po, these boast exceptional strength, hardness, and resistance to corrosion and high-temperature stress. However, they know little about the critical failure mechanism, “irradiation creep.”

This is the deformation of materials over time when exposed to radiation and stress. “We need to know how long they can survive in a fusion reactor before they become brittle,” Po said.

A sophisticated methodology involving high-temperature deformation experiments helped researchers gain a deeper understanding. Po said, “The advantage with this method is that we’re able to rationalize what we’ve observed in experiments into models and equations, and then we test the models and experiments at the same scale.” This dual approach aims to predict and improve the alloys’ performance. Ultimately, enhancing the performance of these alloys could bring us closer to commercialized nuclear fusion reactors.

“Fusion power can literally change the world,” Po concluded.