Engineers at Duke University demonstrated the ability to print functional and recyclable electronic components at a sub-micrometer scale. Their achievement provides an eco-friendly alternative for the electronic display industry. Finding a green option is crucial for an industry that currently faces major environmental challenges.

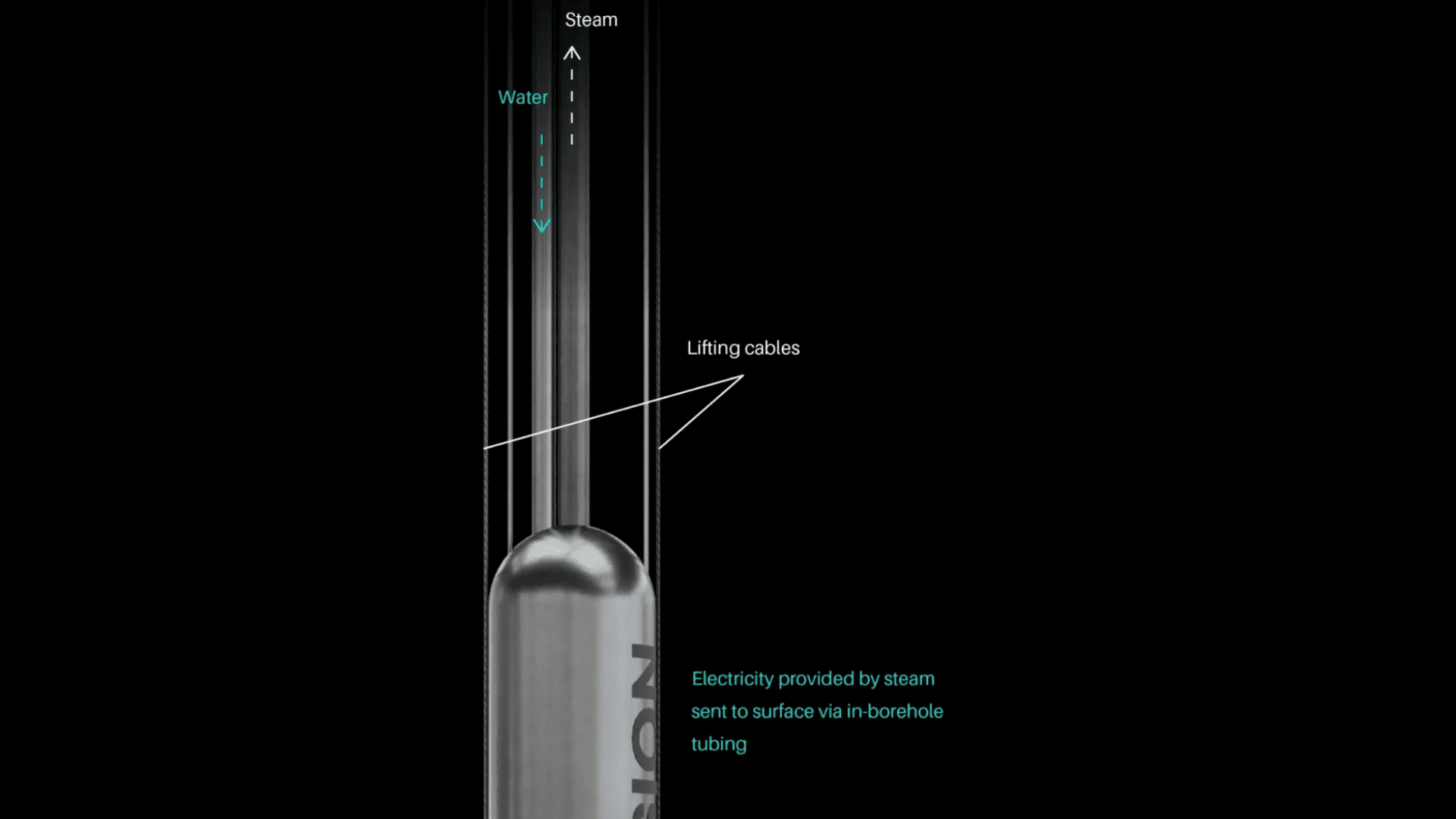

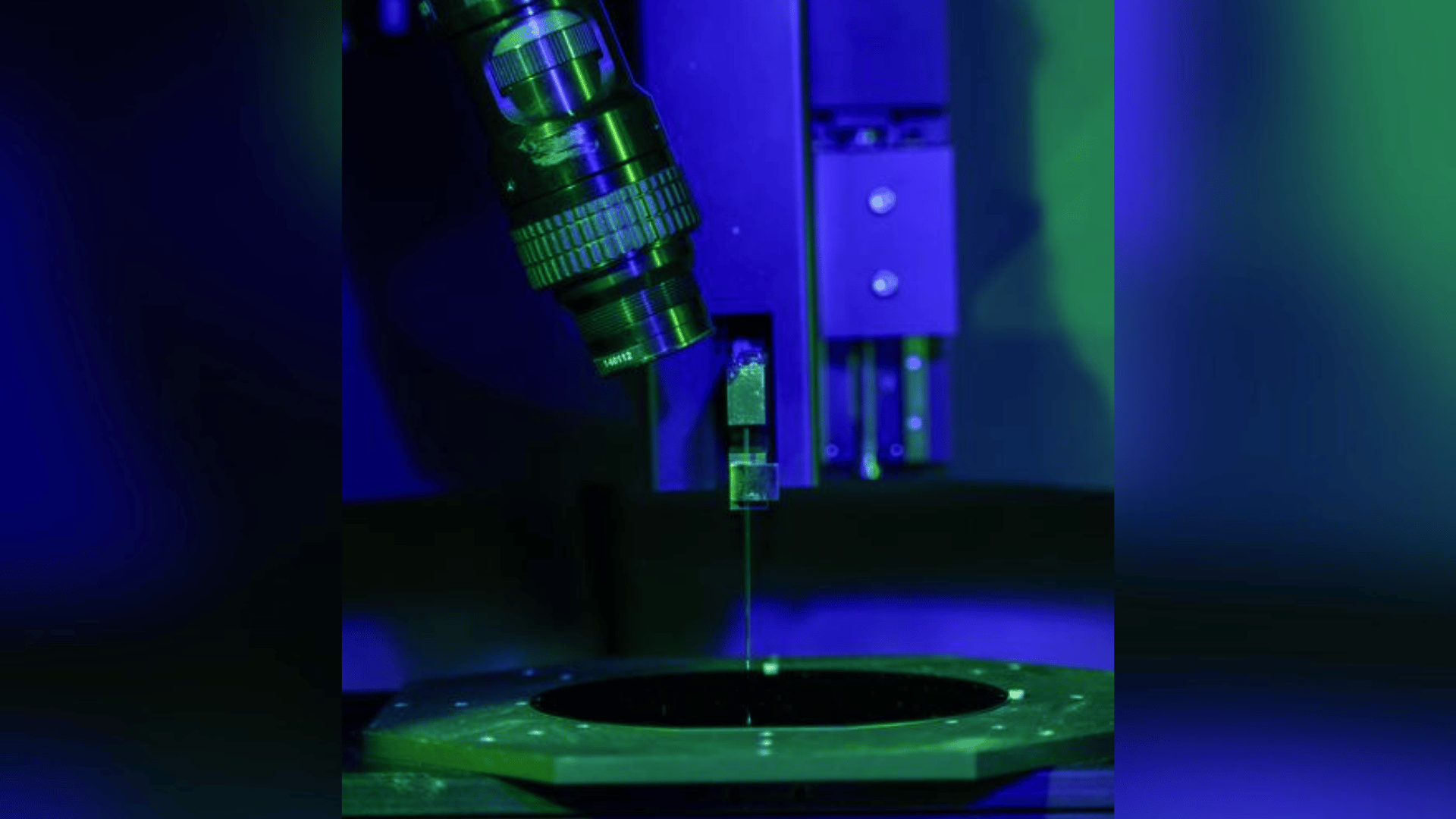

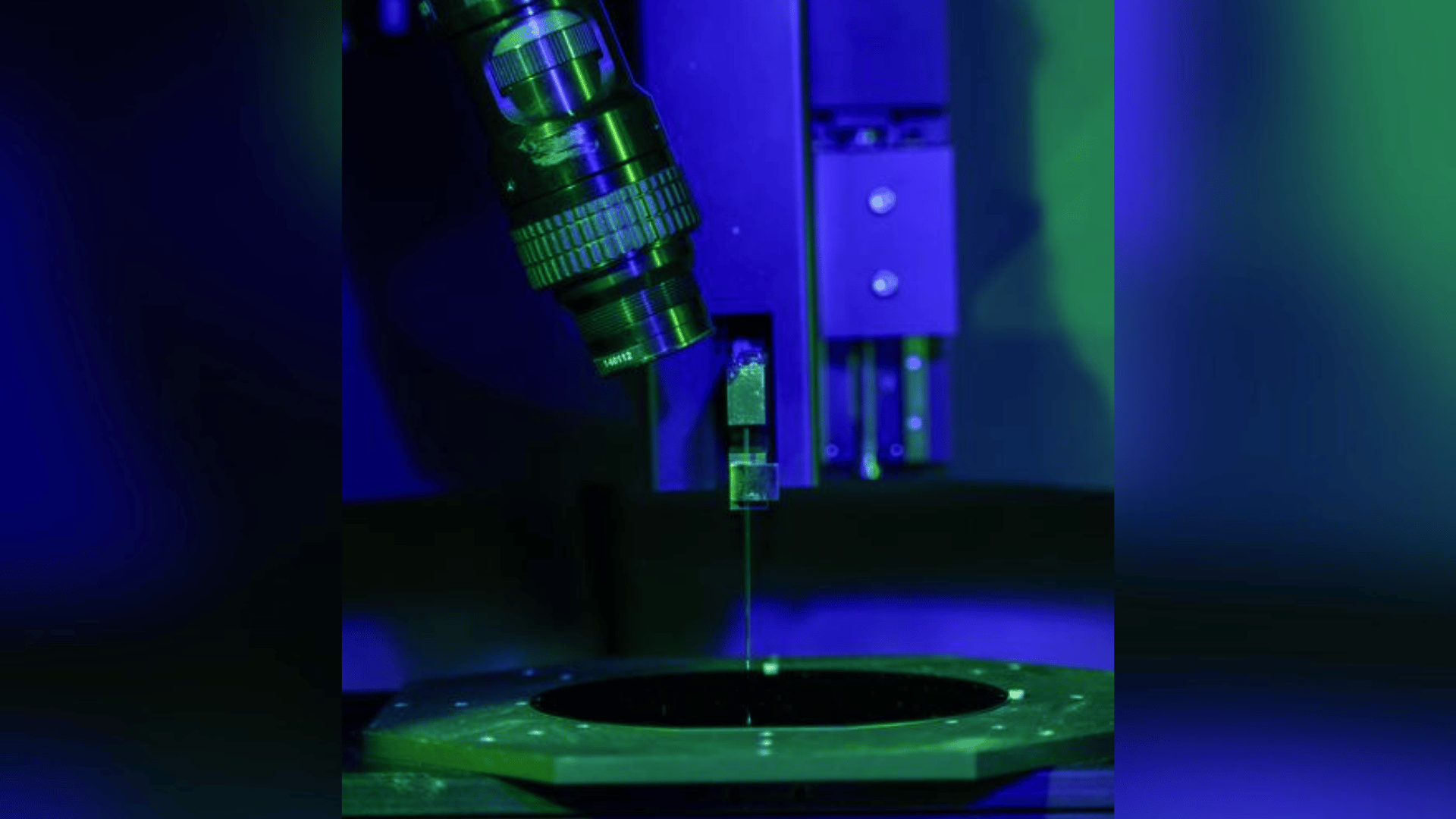

Engineers utilized new hardware and ink chemistry, allowing for ultra-fine printing resolution. In addition, the engineering team partnered with Hummink Technologies to also utilize “high precision capillary printing.” According to the team, the technique uses natural forces, the same phenomenon that absorbs liquid into a paper towel, to dispense tiny amounts of specialized ink through a minute pipette.

Carbon Inks Achieve Industry-Comparable Performance

The researchers used three carbon-based inks that can be printed onto rigid substrates and flexible materials. For example, it can be printed onto glass or paper. These inks allow the devices to be fully recycled, addressing the alarming statistic that less than a quarter of global electronic waste is currently recycled.

Advertisement

The high-precision printing method allows the creation of features tens of micrometers long with tiny, sub-micrometer gaps. These small, consistently formed gaps define the channel length of the resulting thin-film transistors (TFTs). A smaller channel length directly translates to strong electrical performance, which Franklin believes is nearing the standard required to drive OLED displays.

Franklin views digital displays as the most immediate and promising application. He says that the process yields fully recyclable components and requires significantly less energy. In addition, it produces fewer greenhouse gas emissions than traditional vacuum-based TFT manufacturing.

“If we want to seriously increase U.S.-based manufacturing in areas dominated by global competitors, we need transformational technologies,” Franklin said. “Our process prints carbon-based transistors that can be fully recycled and provide comparable performance to industry standards. It’s too promising of a result not to be given further attention.”

Franklin admits that the tech won’t replace high-performance chips. However, he is optimistic about its transformative potential in other sectors. While he is optimistic, he points out that the technology will face hurdles.

“The only real obstacle, to me, is getting sufficient investment and interest in addressing the remaining obstacles to realizing the considerable potential,” Franklin concluded.